Voice coil locating and correcting fixture and vibration assembly assembling process

A technology of main positioning parts and voice coils, which is applied in the field of voice coil positioning and correction tooling and vibration component assembly technology. It can solve problems such as broken wires and open circuits, speaker or receiver vibration rubbing rings, and poor performance. It achieves quality assurance, convenient operation, and Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

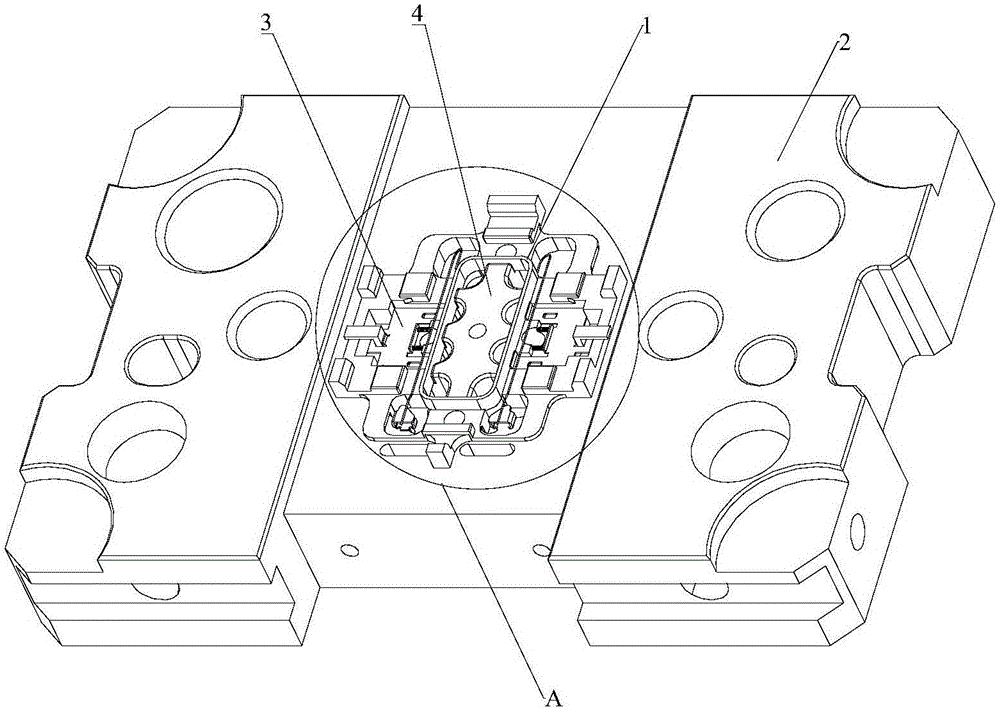

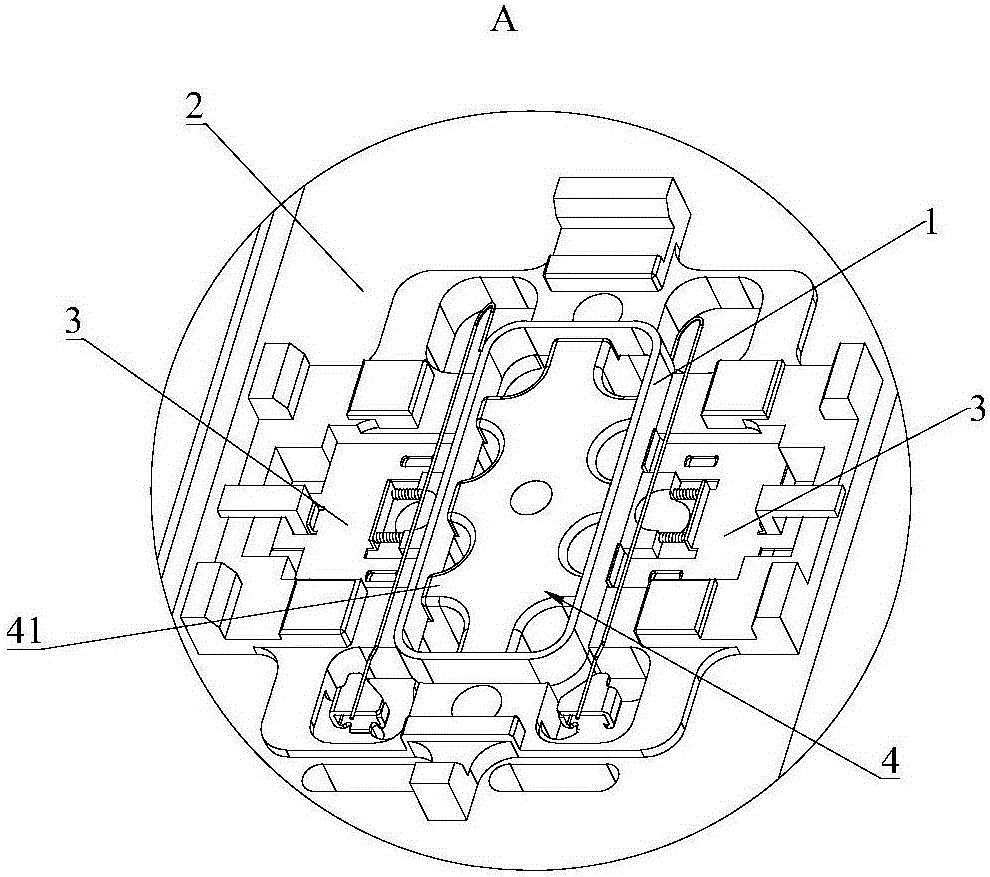

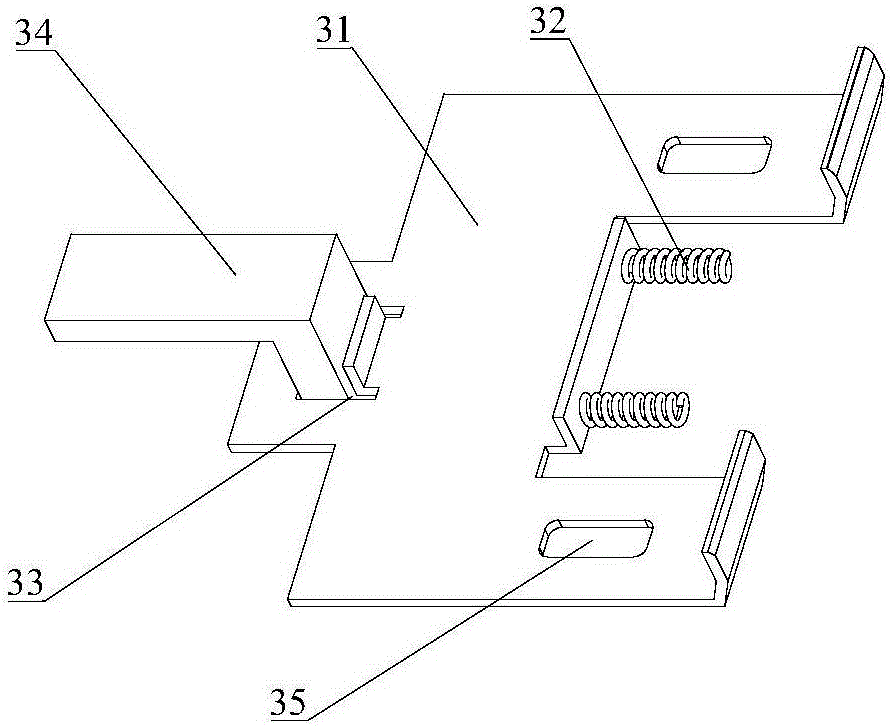

[0047] Please refer to Figure 1 to Figure 5, Embodiment 1 of the present invention is: a voice coil positioning and correcting tool, which is used for positioning and correcting the voice coil 1 during the assembly process of a loudspeaker or a receiver. The tool for positioning and correcting the voice coil includes a main positioning piece 2, a secondary positioning piece and a correction device 3. The cooperation between the main positioning piece 2 and the secondary positioning piece can accurately position the voice coil 1, and the correction device 3 can be positioned on the voice coil 1 After positioning, the voice coil 1 is rectified, so that the inner concave or outer drum part of the voice coil 1 returns to the normal state. The positioning method of the voice coil 1 can be internal positioning or external positioning. The main positioning member 2 is provided with a slot 21 matching the shape of the voice coil 1 . In some embodiments, when the voice coil 1 is pos...

Embodiment 2

[0051] Embodiment 2 of the present invention is: a loudspeaker or receiver vibration component assembly process, including the following steps,

[0052] S1, pull the elastic member 32 of the rectification device 3 through the latch 34, make the rectification sheet 31 away from the slot 21 on the main positioning member 2, and insert the latch 34 into the slot 22 on the main positioning member 2;

[0053] S2. Insert the voice coil 1 into the slot 21 of the main positioning part 2;

[0054] S3, install the pot frame on the main positioning part 2, and spot weld the voice coil 1 and the pot frame;

[0055] S4. Pull out the pin 34 from the slot 22, tighten the elastic member 32 and drive the correction piece 31 to squeeze the voice coil 1, and correct the voice coil 1;

[0056] S5, bonding the basin frame, the voice coil 1 and the sound film to form a loudspeaker or receiver vibration assembly;

[0057] S6. Pull apart the elastic member 32 of the correction device 3 again, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com