Thick film heating tube anti-local-dry-burning structure and method

A heat pipe, partial technology, applied in the field of thick film heat pipe anti-local dry burning structure, can solve the problems of difficult detection, no way to detect, affect the life and safety of heat pipe, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with specific embodiments.

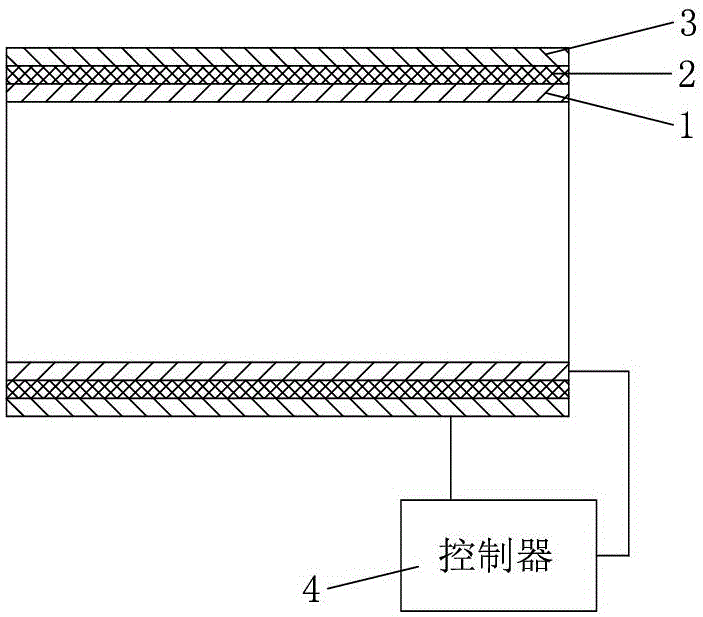

[0028] Such as figure 1 As shown, a thick film heating tube anti-local dry burning structure includes a metal base tube body 1 in the shape of a hollow round tube. The outer circumference of the metal base tube body 1 is provided with an insulating layer whose resistance value changes with temperature. 2. The outer circumferential surface of the insulating layer 2 is provided with a heating element 3 printed by thick film resistive paste.

[0029] Further, the anti-local dry burning structure of the thick film heating tube further includes a controller 4 which is electrically connected to the metal substrate tube body 1 and the heating body 3 respectively.

[0030] Among them, the metal substrate tube body 1 of the present invention can be made of stainless steel or aluminum alloy material, that is, the metal substrate tube body 1 is a stainless steel tube body or an aluminum alloy tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com