A device and method for measuring the start-up pressure gradient of fluid flow in polymer flooding reservoirs

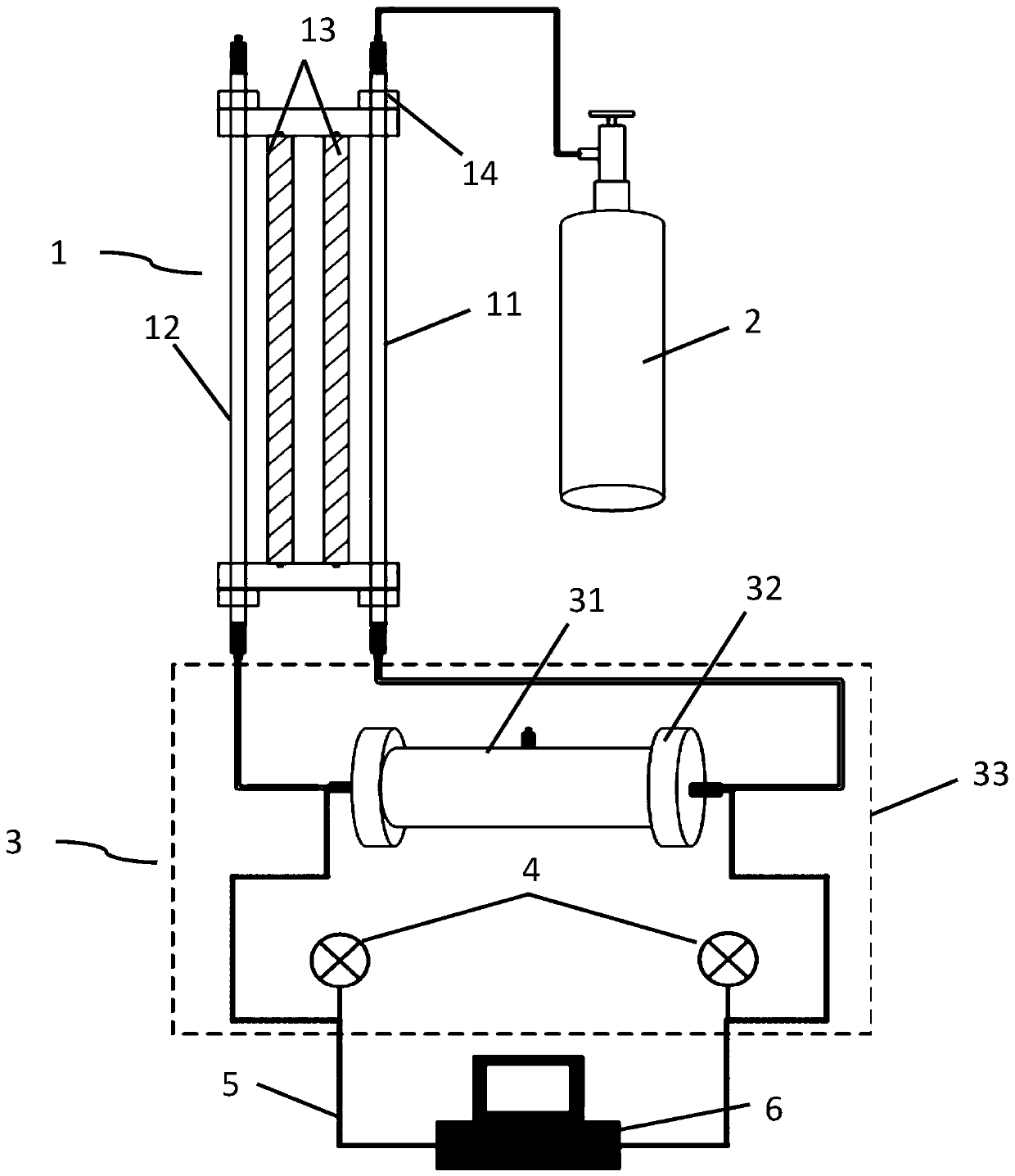

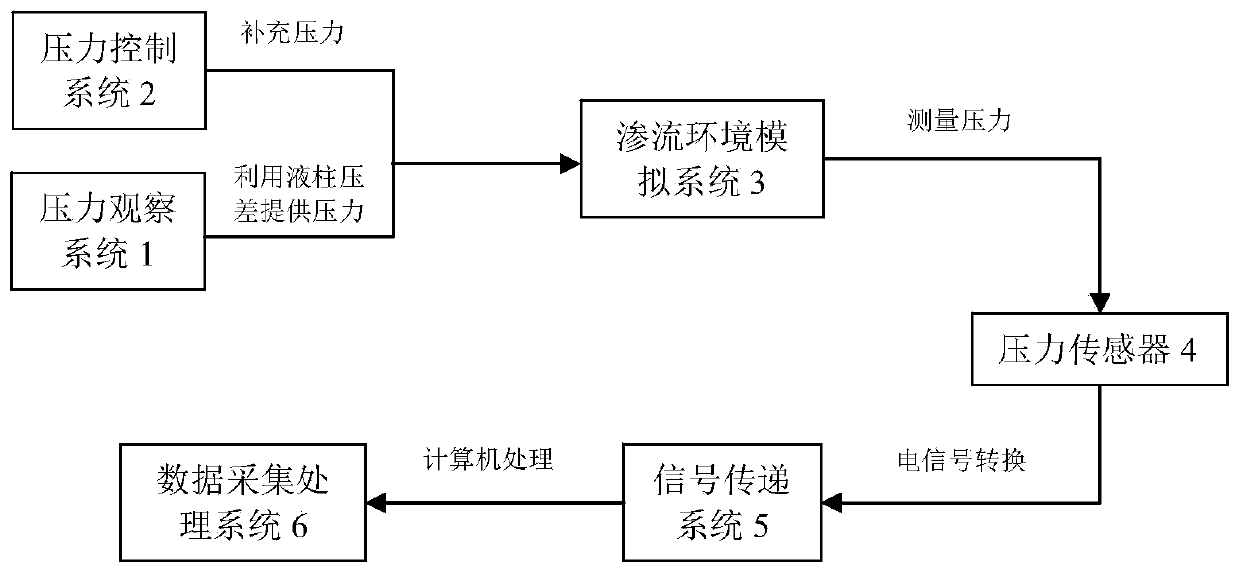

A technology for starting pressure gradient and seepage. It is used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problem of low experimental reliability, long experimental time, and difficulty in flow control. Large and other problems, to achieve the effect of accurate calculation results, intuitive observation results, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

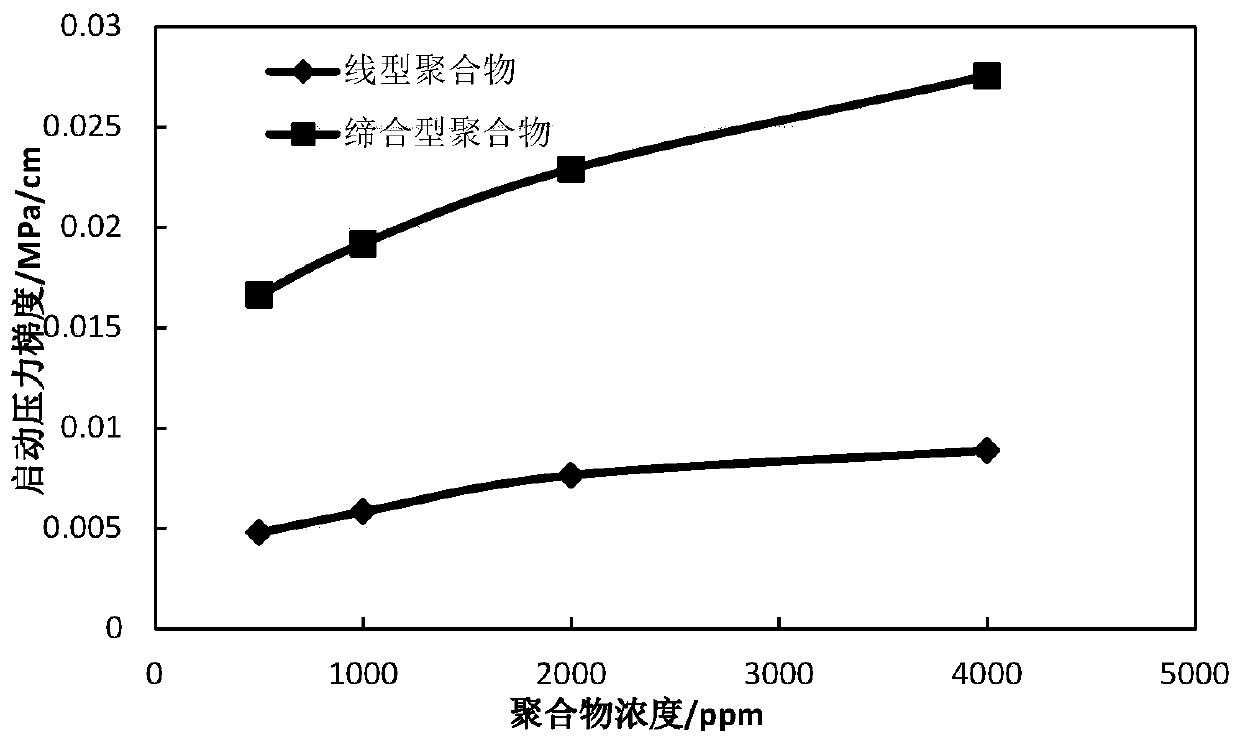

[0041] In this example, the sand-packing pipe 31 is used to simulate a reservoir with a permeability of 500mD, and the linear polymer with a concentration of 500ppm, 1000ppm, 2000ppm, and 4000ppm in the Bohai S oilfield is used as the experimental fluid to simulate the start of seepage when the linear polymer replaces the linear polymer. pressure gradient. Specific steps are as follows:

[0042] 1) Saturate the sand filling pipe 31 with 500ppm linear polymer SNF, place it in the oven 33, preheat it to 57°C, and let it rest for 2 hours.

[0043] 2) Drop a small amount of 500ppm linear polymer SNF into the toughened glass tube 11 at the inlet end and the toughened glass tube 12 at the outlet end to fill the pipeline.

[0044] 3) Gradually add 500ppm linear polymer dropwise to the toughened glass tube 11 at the inlet end, so that the liquid level in the toughened glass tube 11 at the inlet end rises by about 2 cm, and wait for 2 hours after the addition. drop and the liquid lev...

Embodiment 2

[0049] In this example, the sand-packing pipe 31 is used to simulate a reservoir with a permeability of 500 mD, and the concentration of the association polymer in the Bohai Z oilfield is 500 ppm, 1000 ppm, 2000 ppm, and 4000 ppm as the experimental fluid to simulate the displacement of the association polymer. The percolation initiation pressure gradient for the type polymer.

[0050] 1) Saturate the sand filling pipe 31 with 500ppm of associative polymer APP4, place it in the oven 33, preheat it to 65°C, and let it rest for 2 hours.

[0051] 2) Drop a small amount of 500ppm association polymer APP4 into the toughened glass tube 11 at the inlet end and the toughened glass tube 12 at the outlet end to fill the pipeline.

[0052] 3) Gradually add 500ppm of associative polymer dropwise into the toughened glass tube 11 at the inlet end, so that the liquid level in the toughened glass tube 11 at the inlet end rises by about 2 cm, and wait for 2 hours after the addition. If the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com