Syrup viscosity controller of cotton candy machine

A viscosity and controller technology, applied in the direction of viscosity control, non-electric variable control, control/regulation system, etc., can solve the problem of low precision and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0013] The invention provides a high-precision syrup viscosity controller for flower sugar machines.

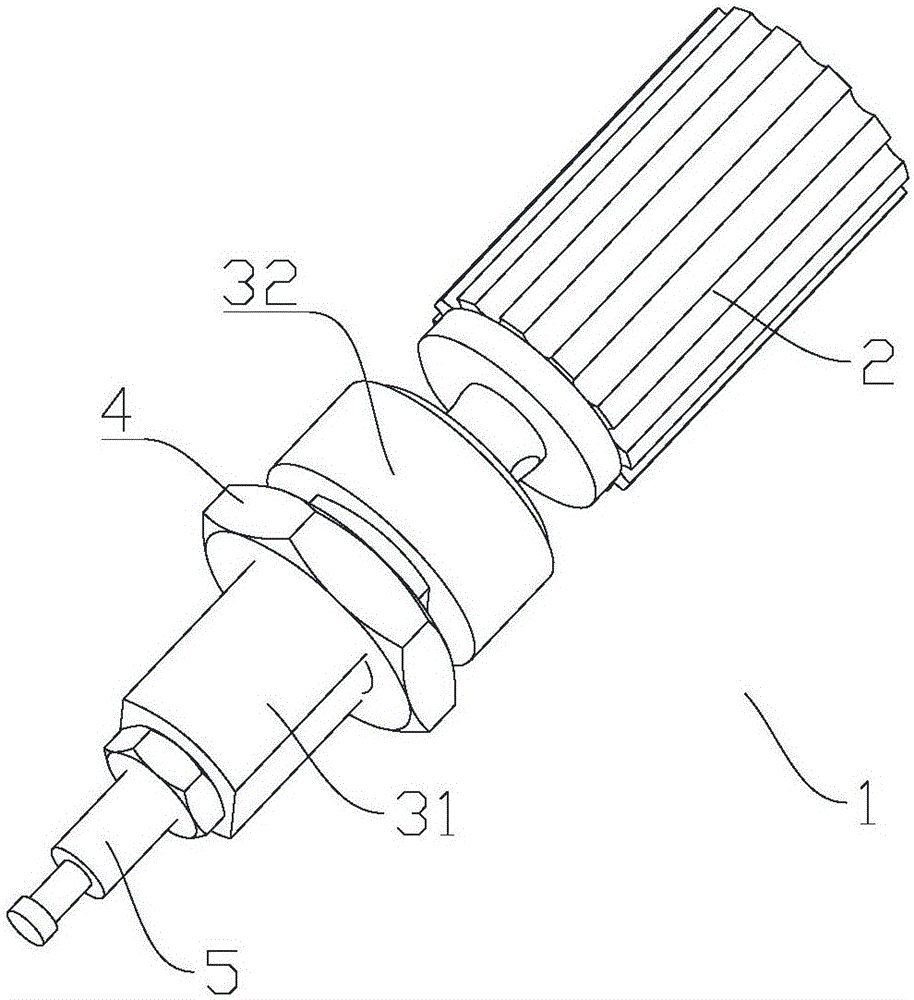

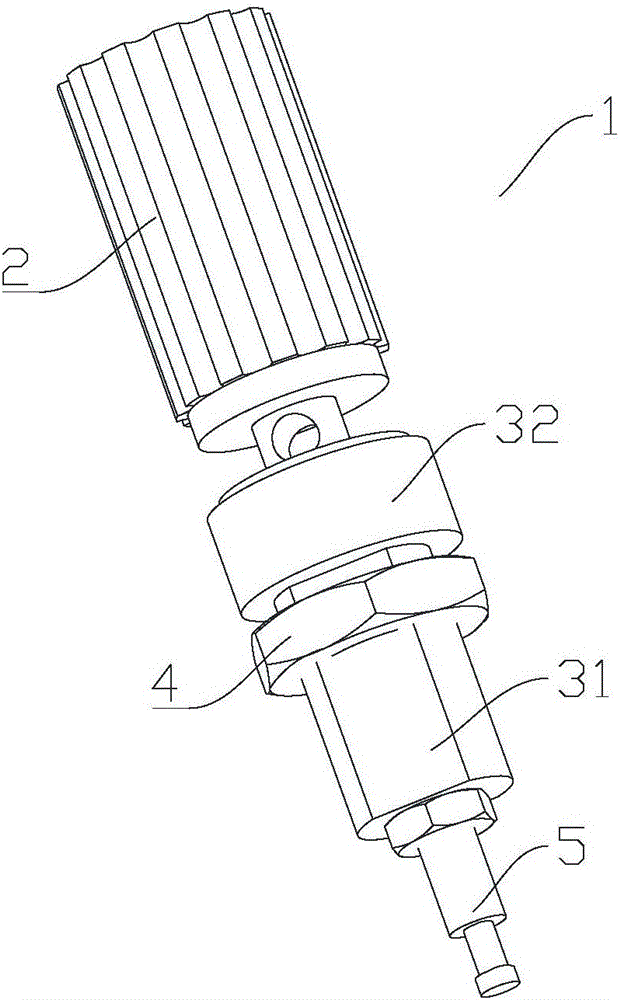

[0014] Such as figure 1 , figure 2 As shown, a flower sugar machine syrup viscosity controller 1 includes a control knob 2, a rotating shaft 31 is arranged on the control knob 2, and an extrusion sleeve 32 is arranged on the rotating shaft 31. A fastening screw 4 is also provided on the rotating shaft 31 , and a spout 5 is provided at the end of the rotating shaft 31 .

[0015] Such as figure 1 , figure 2 As shown, the surface of the control knob 2 is provided with anti-slip threads.

[0016] Such as figure 1 , figure 2 As shown, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com