Method for performance index prediction and coverall quality evaluation of sinter

A technology for quality evaluation and sintering ore, applied in neural learning methods, special data processing applications, instruments, etc., can solve the problems of not fully considering the impact, lack of prediction models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

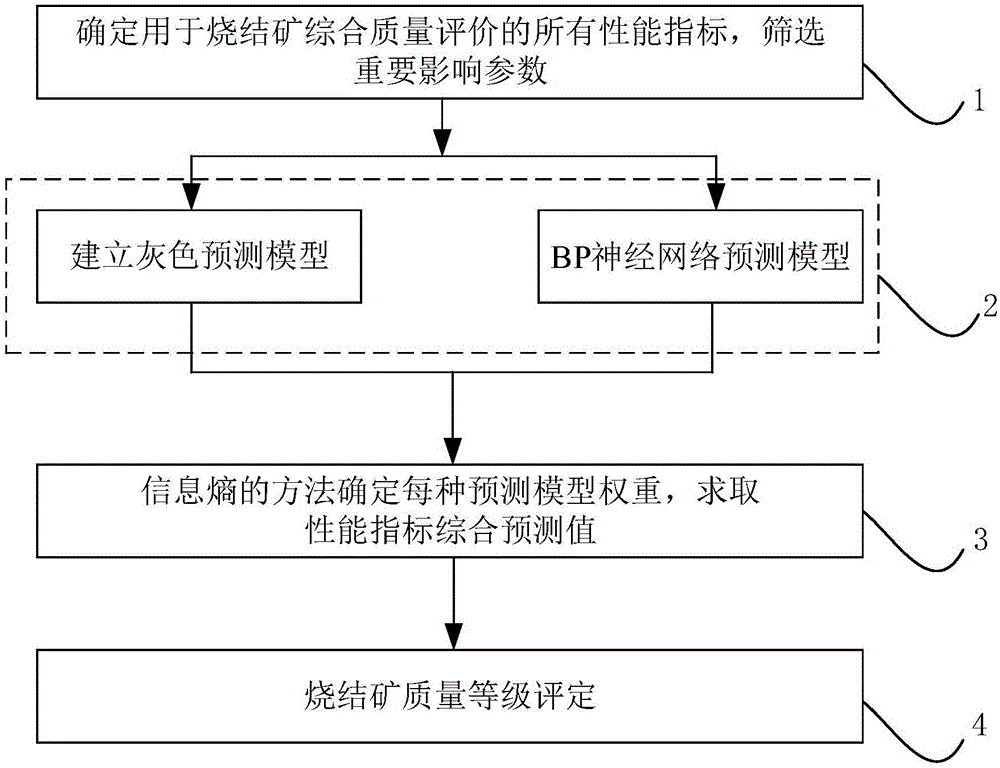

[0100] Such as figure 1 As shown, a method for sinter performance index prediction and comprehensive quality evaluation, the method includes the following steps:

[0101] Step (1): Determine all the performance indicators used for the comprehensive quality evaluation of sinter, and determine the important influencing parameters corresponding to each performance indicator according to the gray correlation degree method;

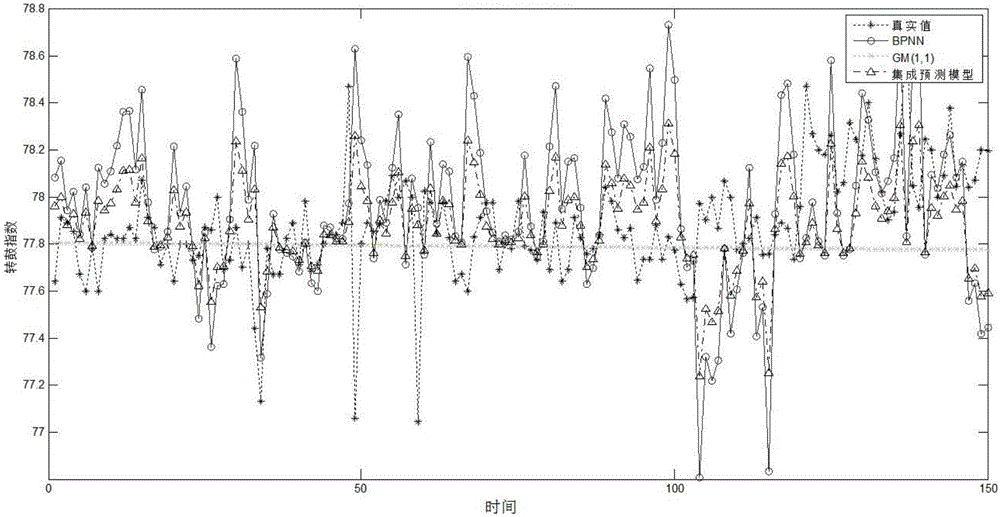

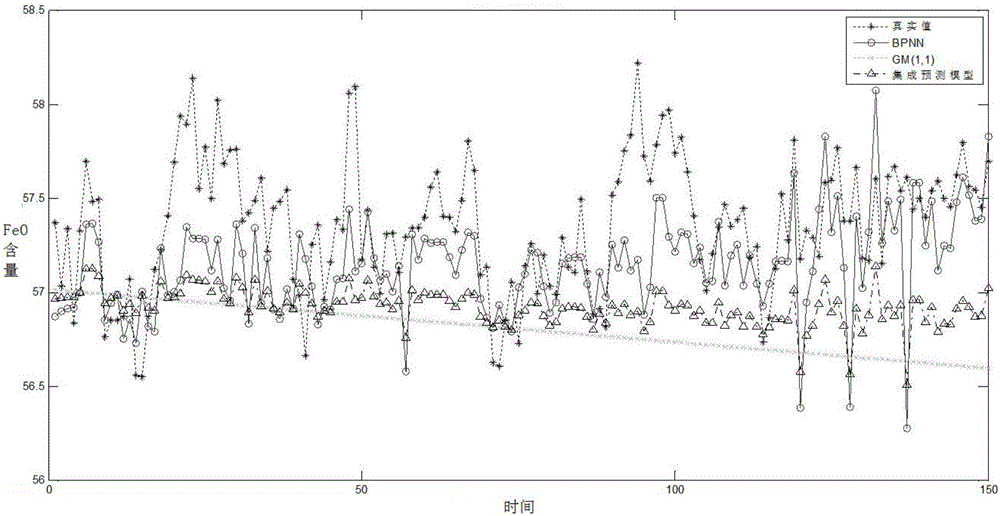

[0102]Step (2): Establish two independent prediction models for each performance index respectively, and described prediction model is used for predicting each performance index value, two independent prediction models comprise gray prediction model and BP in the present embodiment Neural network prediction model, the gray prediction model is a prediction model based on time series, the input of the BP neural network prediction model is an important influence parameter corresponding to the corresponding performance index, and the output of the BP neural networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com