Mounting structure for spray tube with real-time observation function in dynamic powder sterilization cabinet

A technology of installation structure and spray pipe, which is applied in the direction of water supply equipment, sanitary equipment for toilets, heating, etc., can solve the difficulty for operators to move inside the sterilization cylinder, cannot observe the sterilization cylinder in real time, and enlarge Difficulty cleaning the sprinkler pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

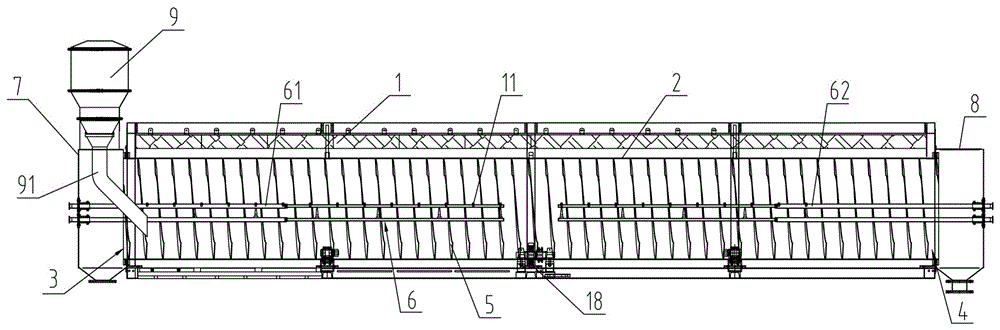

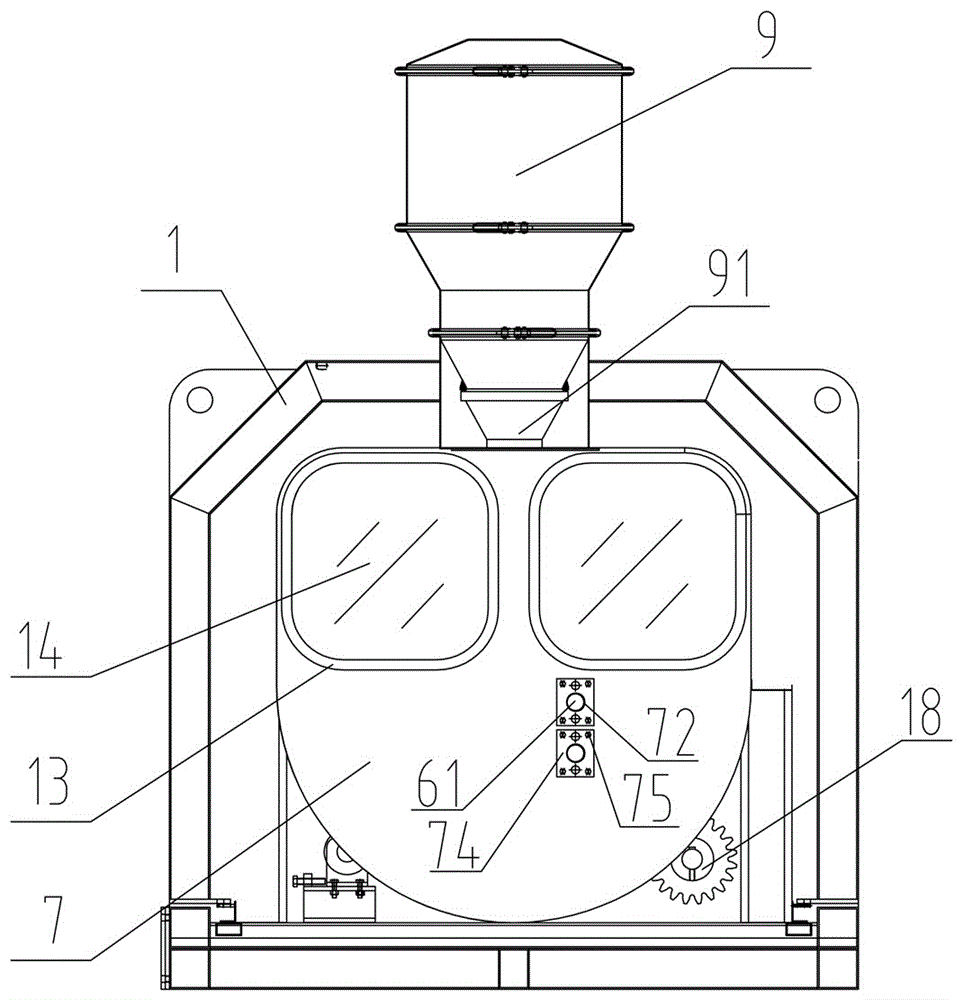

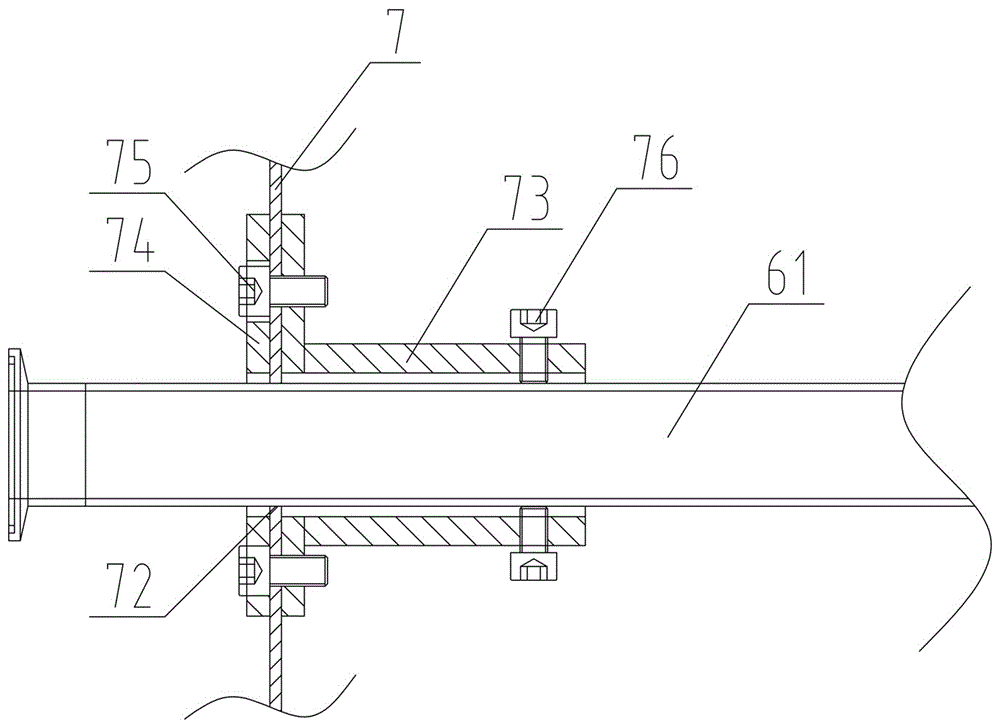

[0016] Such as figure 1 , figure 2 As shown, the installation structure of the spray pipe with real-time observation in the powder dynamic sterilization cabinet includes: a frame 1 and a sterilization cylinder 2 installed on the frame 1, and the front and rear ends of the sterilization cylinder 2 are respectively set There is a feeding port 3 and a feeding port 4, and the frame 1 on the side of the feeding port 3 is provided with a feeding bucket 9 for storing the powder to be sterilized, and the bottom of the feeding bucket 9 is provided with a The feed pipe 91 in the mouth 3, the powder granules in the feeding bucket 9 can be thrown into the sterilization cylinder 2 through the feed pipe 91, and the inner wall of the sterilization cylinder 2 is provided with a The port 3 is transported to the spiral gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com