An economical plastic mold steel plate and its manufacturing method

A plastic mold, economical technology, applied in the field of economical plastic mold steel plate and manufacturing, can solve problems such as cost increase, increase production cost, prolong production cycle, etc., and achieve the effect of reducing raw material cost, increasing content, and improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

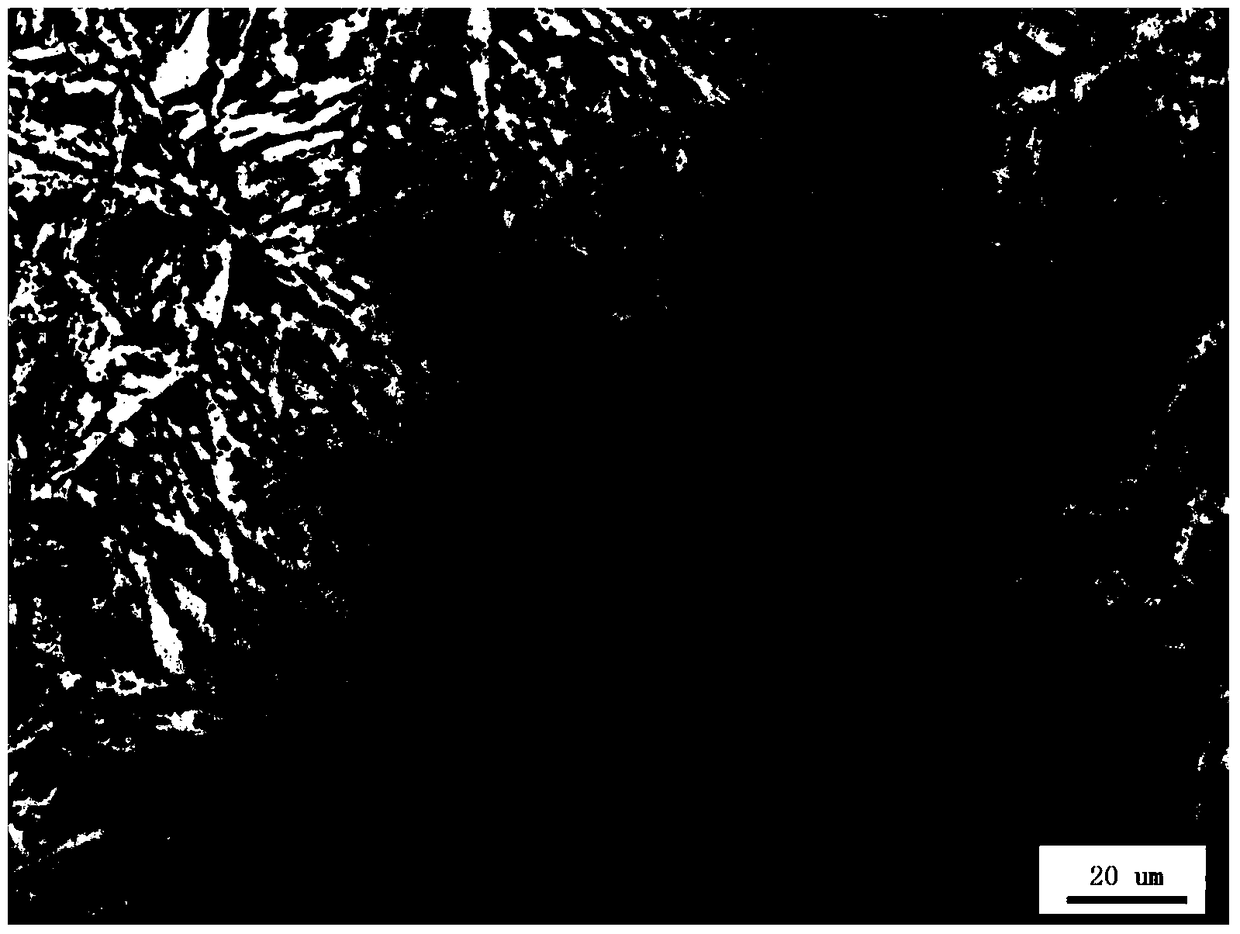

Image

Examples

Embodiment Construction

[0030] Below by embodiment the present invention will be further described. The following examples are only some optimal implementation modes of the present invention, and do not limit the scope and technical means of the foregoing invention in any way.

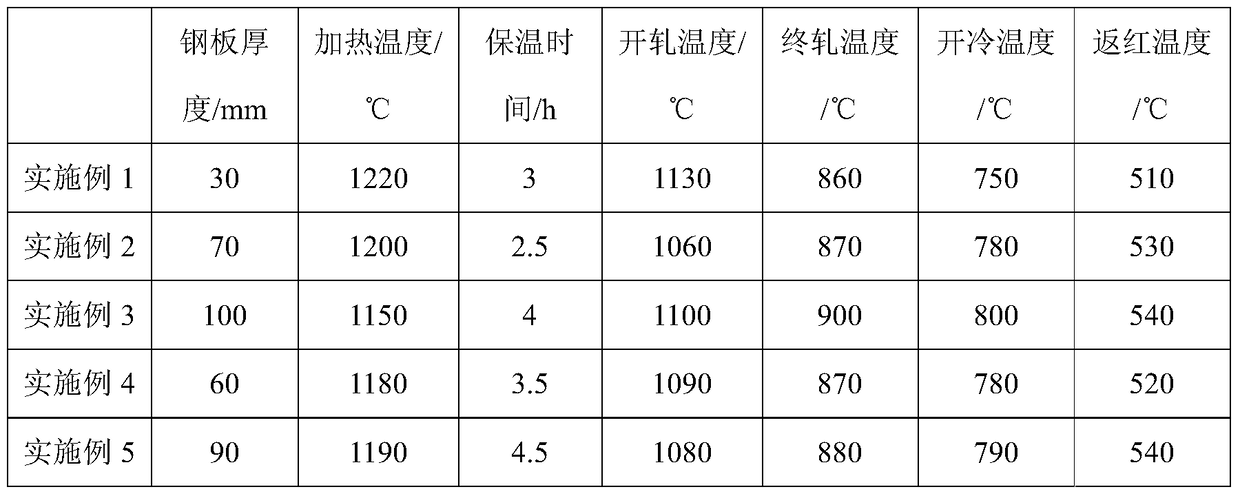

[0031] In the embodiment of the present invention, smelting, continuous casting, furnace heating, rolling, cooling, and heat treatment are carried out according to the composition ratio of the technical solution. The composition of the steel of the embodiment of the present invention is shown in Table 1. See Table 2 for the heating and rolling process parameters of the cast slab of steel in the embodiment of the present invention. See Table 3 for the tempering process and cross-sectional hardness of the steel plate in the embodiment of the present invention.

[0032] Table 1 Composition (wt%) of the steel of the embodiment of the present invention

[0033]

C

Si

mn

Cr

Mo

B

P

S

Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com