Device and method for measuring mechanical seal ring friction

A technology for mechanical seals and measuring devices, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as the inability to meet the needs of friction force measurement, and achieve comprehensive and improved measurement of friction force of mechanical seal rings The effect of reliability and simple experimental principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

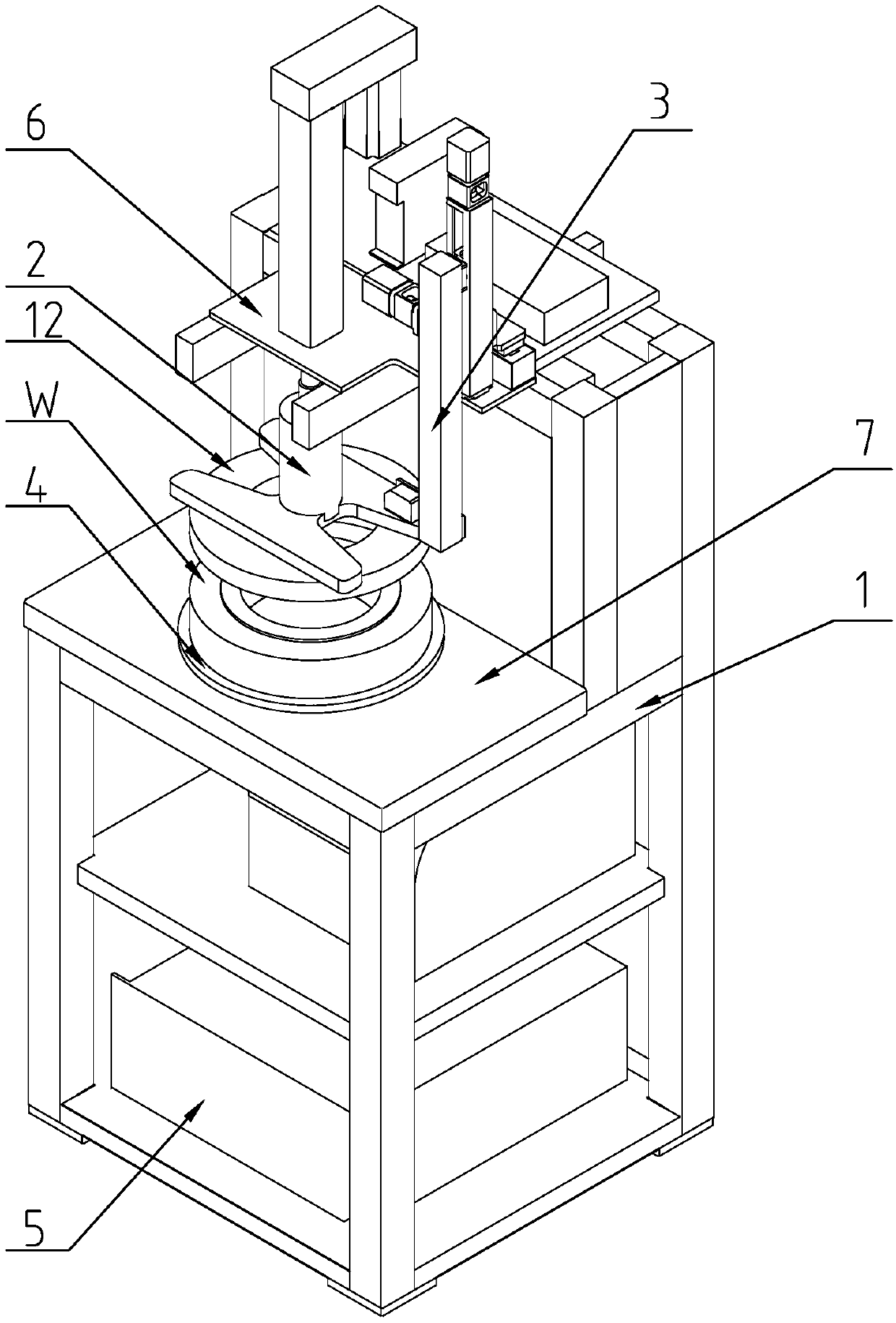

[0033] Such as figure 1 As shown, a mechanical seal ring friction measurement device includes a load and force measurement module 2 for applying pressure to the moving ring 24, a displacement measurement module 3 for measuring the displacement of the moving ring 24, and a device for driving the mechanical seal ring W to rotate along its axis. Turntable module 4, control module 5, frame-shaped base 1, support plate 6 fixed on the top of base 1, workbench 7 fixed in the middle of base 1 and arranged horizontally, loading and force measuring module 2 and displacement measuring module 3 are respectively fixedly connected to the support plate 6, the turntable module 4 is fixed on the workbench 7, and the control module 5 is fixed on the bottom of the base 1;

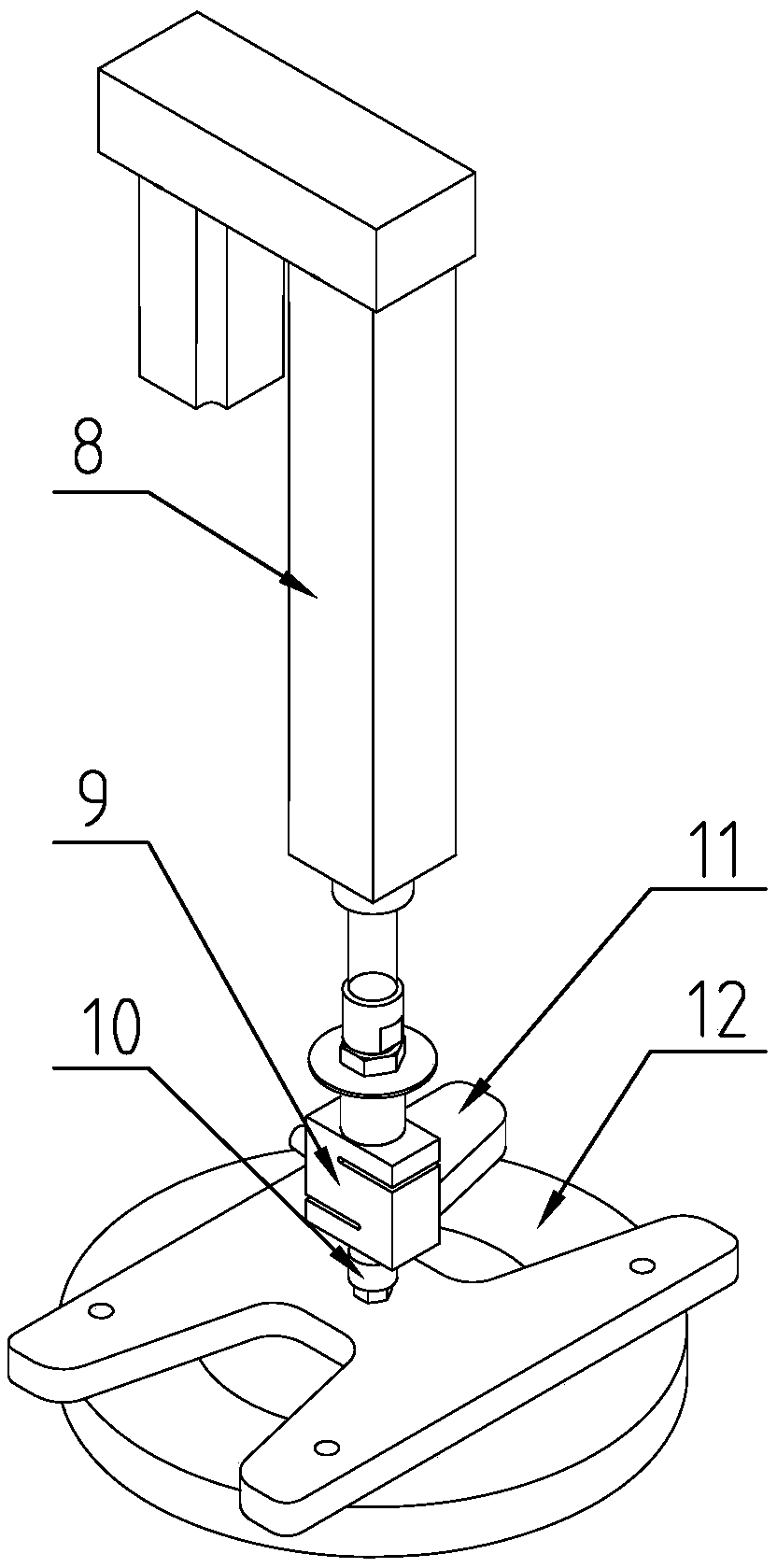

[0034] Such as figure 2 As shown, the loading and force measuring module 2 includes a servo electric cylinder 8, a force sensor 9, a floating joint 10 and a pressure plate 11; the servo electric cylinder 8 is fixed on the s...

Embodiment 2

[0041] A method for measuring the frictional force of a mechanical seal ring, comprising the steps of:

[0042] Preparatory stage: Fix the static ring 12 of the corresponding diameter of the mechanical seal ring W to be measured on the bottom surface of the pressure plate 11, fix the mechanical seal ring W to be measured on the rotary table 23, and input the inherent parameters such as the height and diameter of the mechanical seal ring W Go to the measurement interface, and give the control information so that the servo electric cylinder 8 can move according to a certain rule;

[0043] Measurement stage: the mechanical seal ring W rotates continuously with the rotary table 23 under the drive of the motor 19 (the rotary table 23 is driven to rotate by the conveyor belt 21, and the mechanical seal ring W is fixed on the rotary table 23, and the motor 19 can drive the mechanical seal ring W rotates circumferentially at a certain speed, thereby ensuring the relative rotation betw...

Embodiment 3

[0047] A method for measuring the frictional force of a mechanical seal ring, comprising the steps of:

[0048] Preparatory stage: fix the static ring 12 corresponding to the diameter of the mechanical seal ring W to be measured on the bottom surface of the platen 11, and fix the mechanical seal ring W to be measured on the rotary table 23;

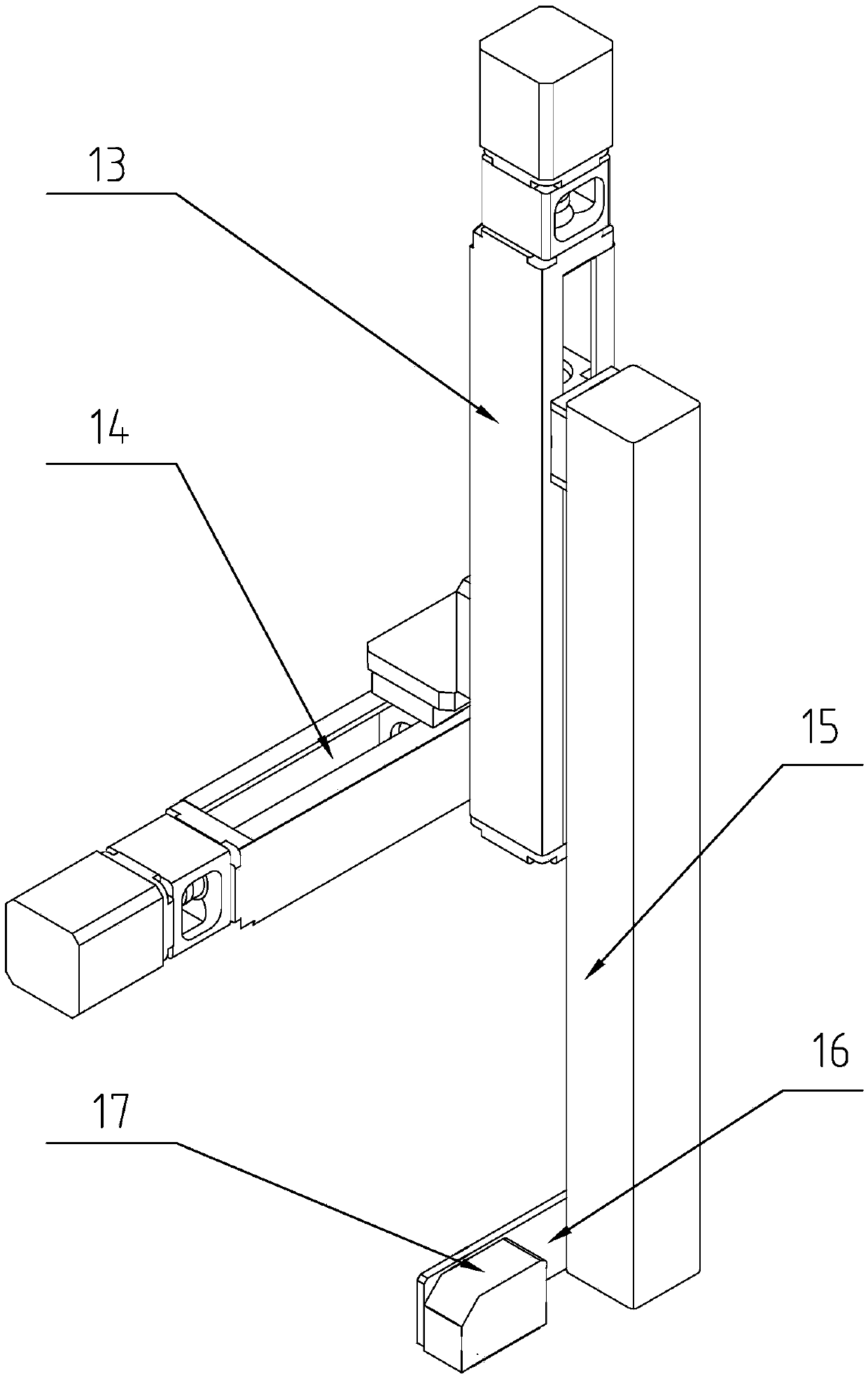

[0049] Measurement stage: the static ring 12 is driven by the servo electric cylinder 8 to move downward in the vertical direction at a fast forward speed, and when the lower surface of the static ring 12 is 0.1-1mm away from the upper surface of the moving ring 24, the static ring 12 temporarily stops downward Movement, control the movement of the X-direction linear module 14 and the Z-direction linear module 13, move the laser displacement sensor 17 to the measurement position, ensure that the upper surface of the static ring is within the effective measurement range of the laser displacement sensor 17, and the static ring 12 is in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com