Composite safety self-destruct syringe

A compound type, syringe technology, applied in the field of syringes, can solve the problems of safety performance restriction, easy operation error, self-destruction of the syringe, etc., and achieve the effect of avoiding medical accidents and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

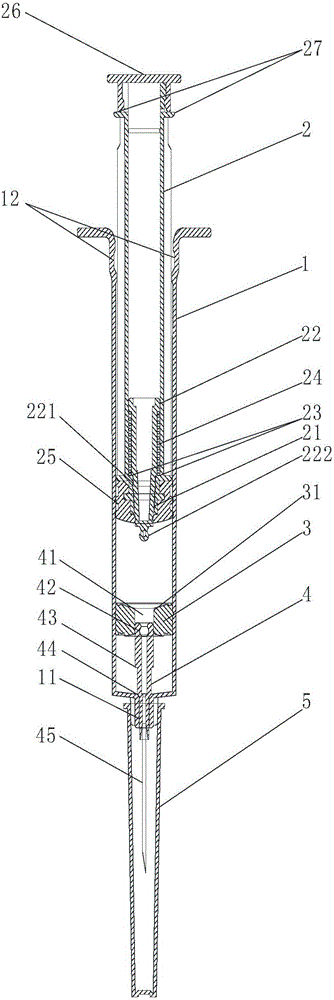

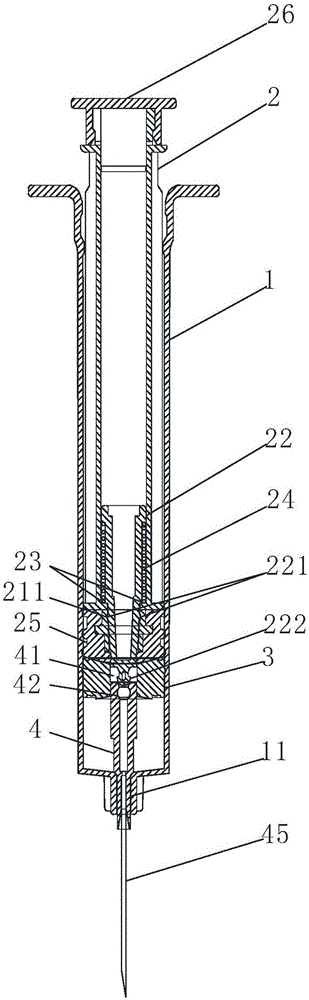

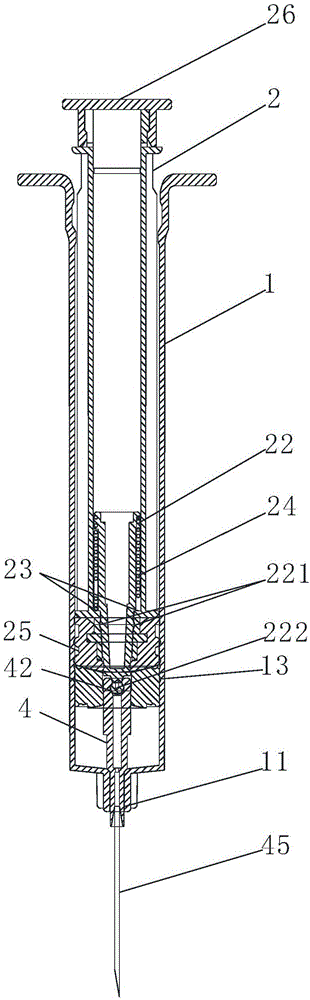

[0027] Such as Figure 1-6 As shown, this embodiment provides a composite safety self-destruct syringe, including:

[0028] Injection cylinder 1, the bottom wall of the injection cylinder 1 is radially retracted to form a first bayonet 11;

[0029] Injection rod 2, the injection rod 2 is movably connected in the injection cylinder 1, and the lower end of the injection rod 2 is tightly fitted with the inner wall of the injection cylinder 1, the inside of the injection rod 2 is a cavity, and the bottom wall of the injection rod 2 is radially retracted to form a The second bayonet 21, the spring sleeve 22 that can move upward relative to the injection rod 2 is installed under the cavity of the injection rod 2, the outer wall of the spring sleeve 22 is provided with a first stop convex point 221, and the inner wall of the second bayonet port 21 is provided with There is a first groove 211 that engages with the first stop convex point 221, and a contact portion 23 is provided unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com