Automatic blade-assembling equipment of oil pump motor

An oil pump motor and blade installation technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low degree of automation, easy fatigue, affecting product quality, etc., to improve production and assembly efficiency, easy to use and save. human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

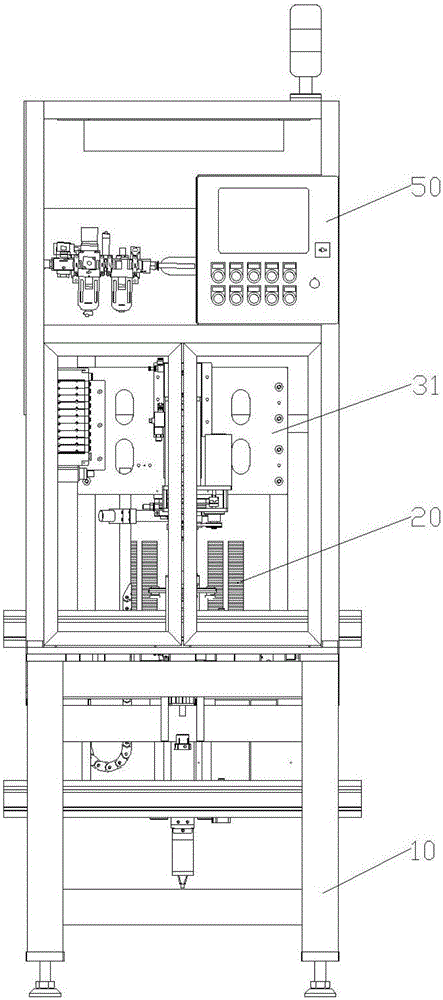

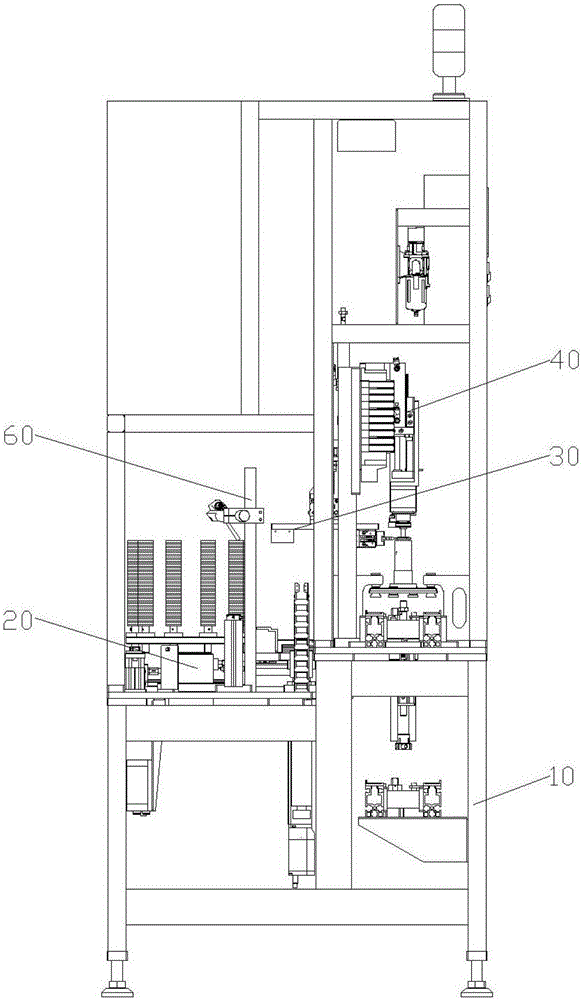

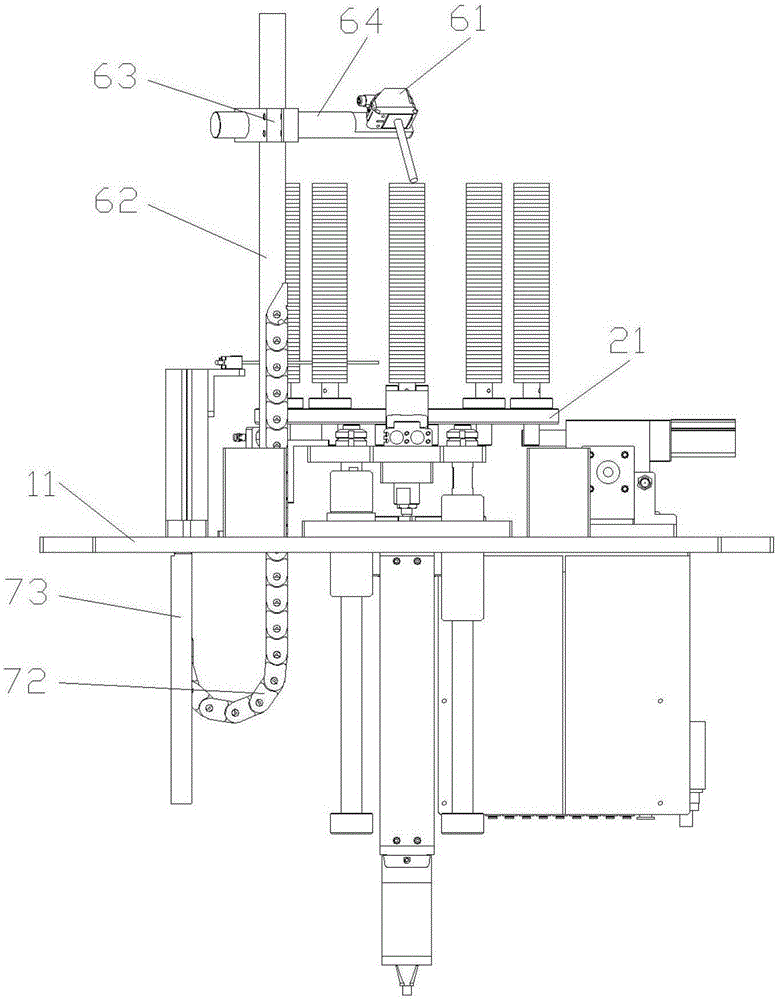

[0020] see Figure 1 to Figure 6 , a kind of oil pump motor automatic vane installation equipment described in the present invention, comprises frame 10 and the turntable feeding mechanism 20 that is arranged on frame 10, picks and unloads mechanism 30, blade pressing mechanism 40 and operation control mechanism 50. The turntable feeding mechanism 20 includes a feeding turntable 21 with several stations. One side of the feeding turntable 21 is provided with a visual detection mechanism 60 that can automatically identify the front and back of the blade. The loading and unloading mechanism 30 includes a mounting stand 31 , a column 32 , a rotating arm 33 and a rotating cylinder 34 for driving the rotating arm 33 to rotate horizontally. The install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com