chemical mechanical polishing device

A chemical machinery and polishing device technology, applied in grinding devices, grinding/polishing equipment, grinding machine tools, etc., can solve problems such as inability to accurately judge, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

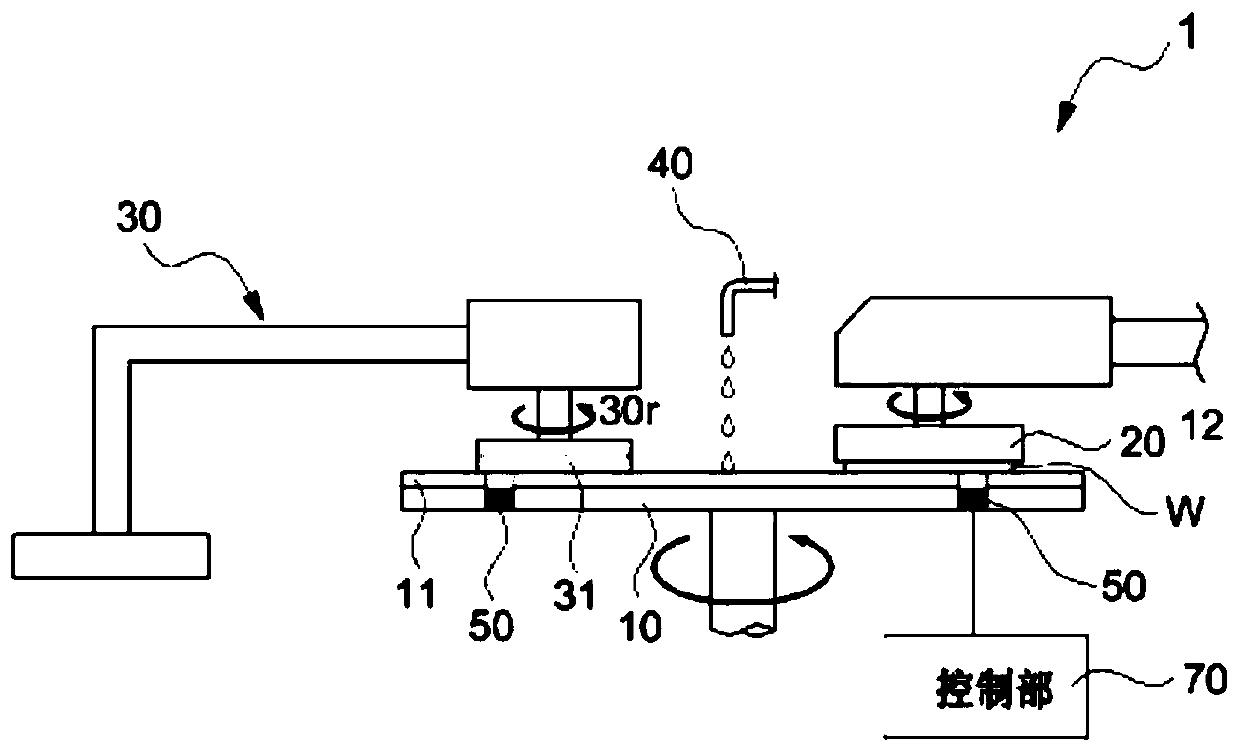

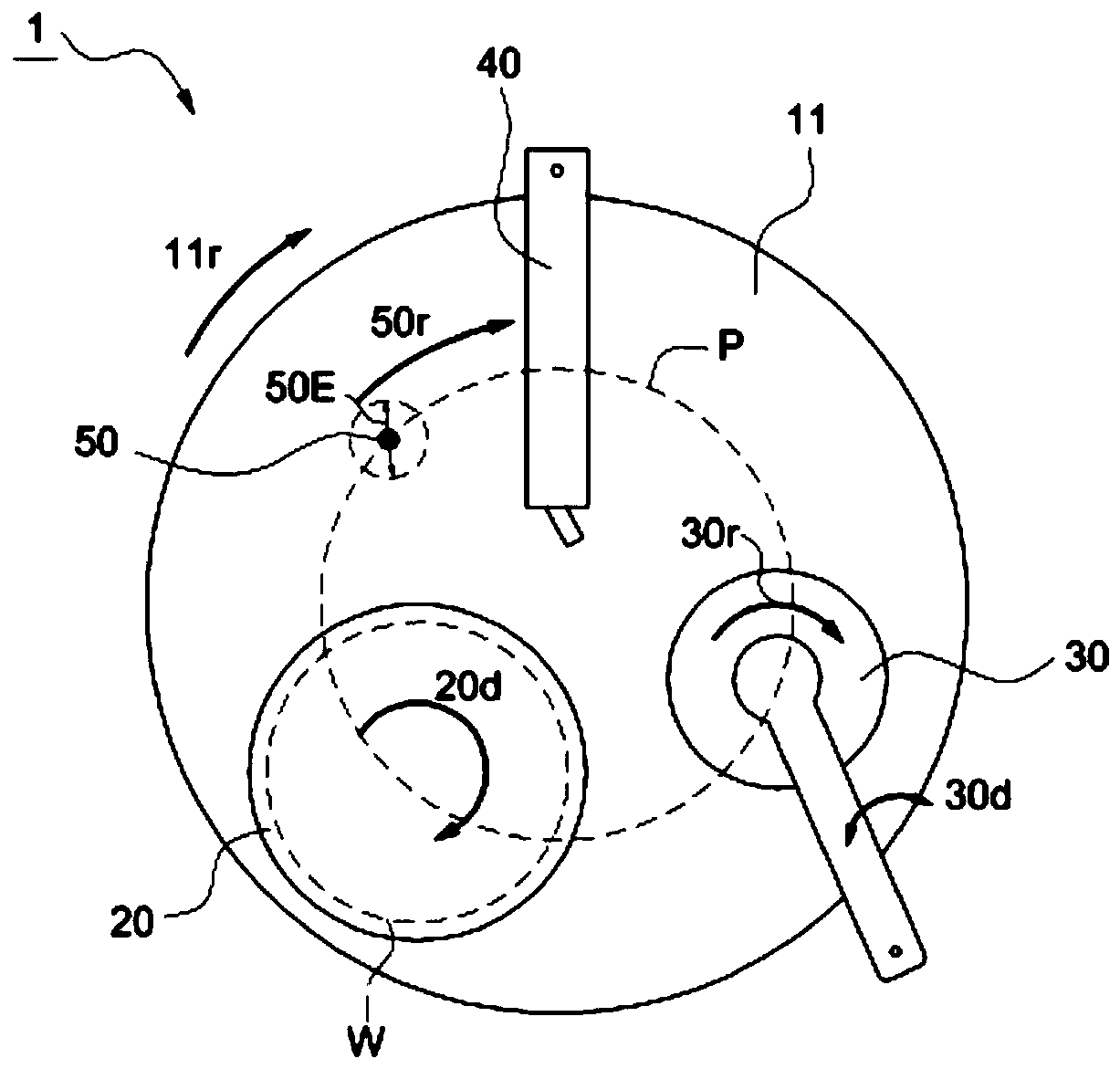

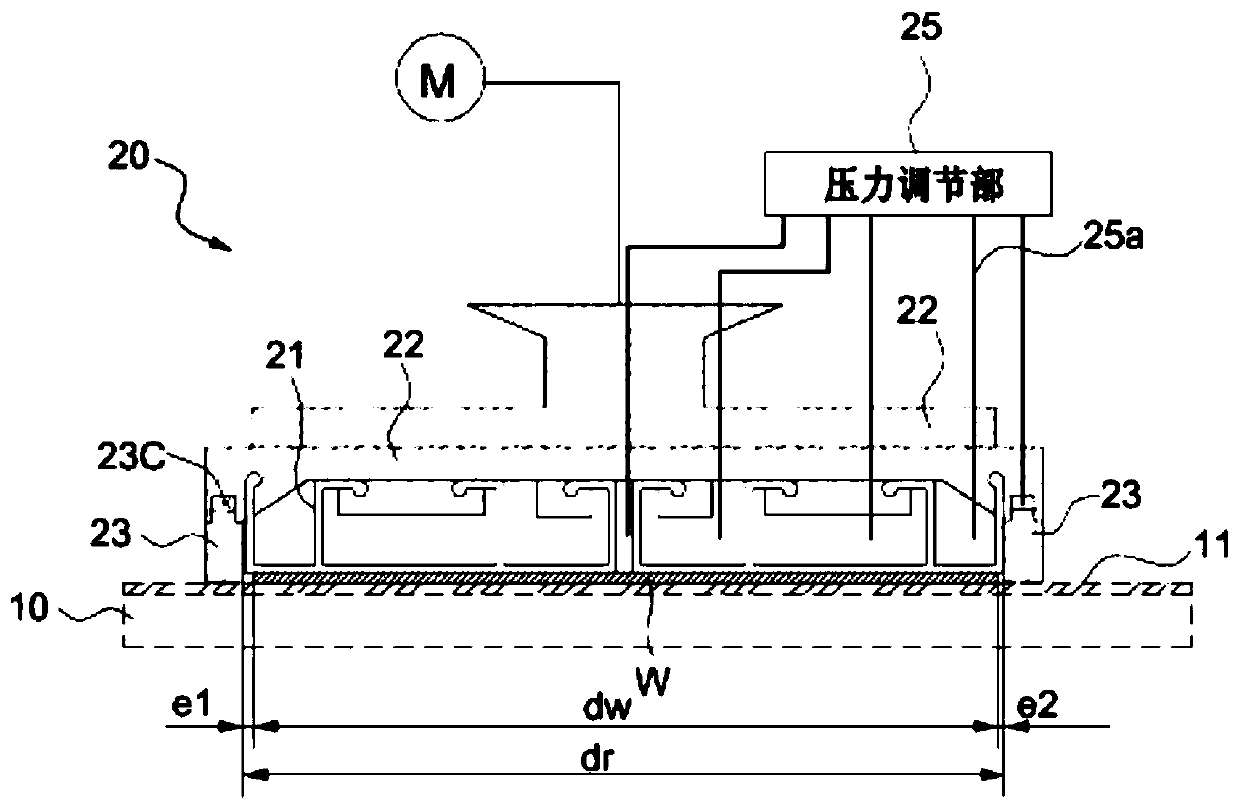

[0052] Next, a chemical mechanical polishing device 9 according to an embodiment of the present invention will be described in detail with reference to the drawings. However, in describing the present invention, detailed descriptions of well-known functions and configurations will be omitted in order to clarify the gist of the present invention.

[0053] A chemical mechanical polishing device 9 related to an embodiment of the present invention includes: a polishing flat plate 10 covered with a polishing pad 11, and the above-mentioned polishing pad 11 is in contact with the polishing layer of the wafer W formed with a conductive polishing layer to achieve polishing; The head 100 pressurizes the wafer W while it is on the bottom surface and rotates the wafer W; the thickness sensor 50 applies an eddy current to detect the thickness of the polishing layer of the wafer W and receives an output signal from the polishing layer; and the control unit 90 An AC current is applied to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com