Tensioned anchor leg buoy for single point oil unloading system

An oil unloading system and tensioning technology, which is applied in the direction of anchorage arrangement, cargo handling equipment, ship construction, etc., can solve the problems of shortening the hose replacement cycle, reducing the service life cycle of the hose, and hose damage, so as to increase the additional Effects of quality, increasing distance, and increasing restoring moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

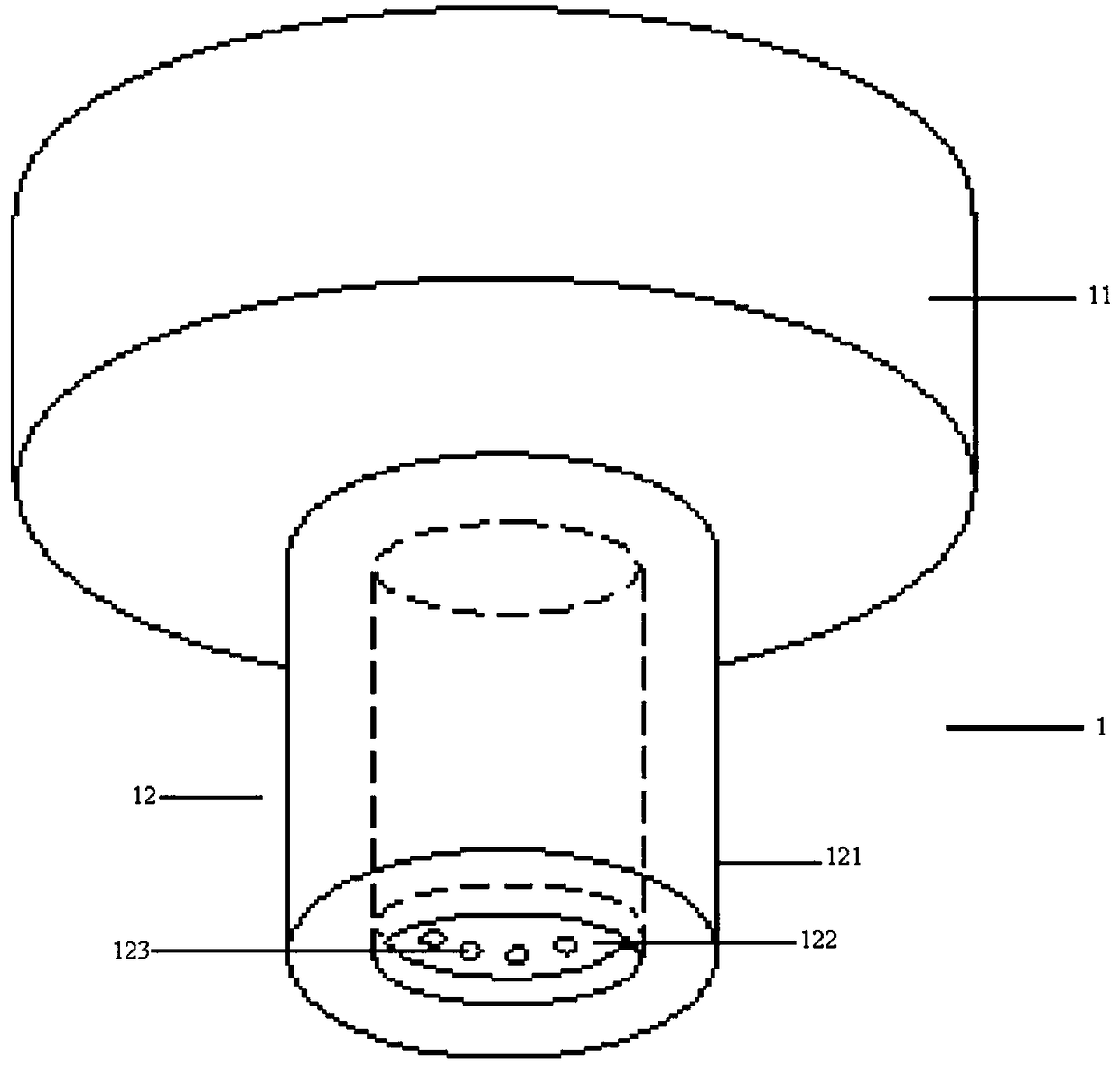

[0019] Such as figure 1 As shown, the present invention is based on the tensioned anchor leg buoy of the traditional single-point oil unloading system, which includes a catenary anchor leg buoy 1, and the catenary anchor leg buoy 1 includes a buoyancy mooring part 11, through which the buoyancy system The mooring part 11 can ensure that the present invention stays on the water surface, and can moor the oil hose. The buoyant mooring part 11 is cylindrical, and the bottom of the buoyant mooring part 11 has a damping ballast part 12. The damping ballast part 12 includes an annular barrel 121 installed at the center of the bottom of the buoyant mooring part 11, and the inner cavity of the annular barrel forms a ballast tank to form a ballast effect on the buoy to stabilize the area.

[0020] The present invention also makes full use of the heave plate technology. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com