Screw conveyor

A screw conveyor, screw conveying technology, applied in the direction of conveyor, transportation and packaging, packaging, etc., can solve the problems of accelerated network chain wear, increased use cost, shortened service life of conveying network chain, etc., to reduce the tension force , to ensure the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

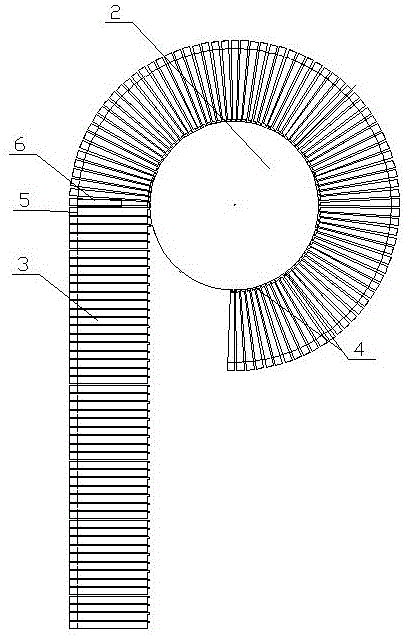

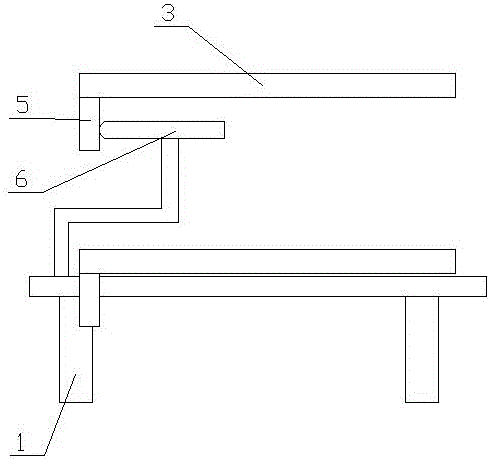

[0009] Such as figure 1 , 2 As shown, the present invention includes a spiral frame 1, on which is installed a spiral conveying net chain 3 driven by a rotating drum 2, and the inner side of the rotating drum 2 and the spiral conveying net chain 3 is provided with mutual engagement The lower end surface of the outer side of the curved conveyor network chain 3 is provided with a retaining strip 5, and the input end of the screw conveyor and the position where the turning cylinder 2 turns are provided with a top plate 6 connected to the spiral frame 1. The top plate 6 is arranged inside the baffle 5, and the outer end is pressed against the baffle 5 outward.

[0010] In addition, it is well known that bolt conveyors are divided into two different types: upward conveying and downward conveying. Therefore, the top plate of the upward conveying screw conveyor is provided with the input end of the bottom of the screw conveyor, and the top plate of the downward conveying screw conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com