A high-strength austenitic stainless steel for economical rail vehicles and its manufacturing method

A technology for austenitic stainless steel and rail vehicles, applied in the field of austenitic stainless steel, can solve the problems of rising stainless steel costs, long production and processing procedures, weak corrosion resistance, etc., to meet the requirements of lightweight, reduce the weight of the car body, improve The effect of body strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

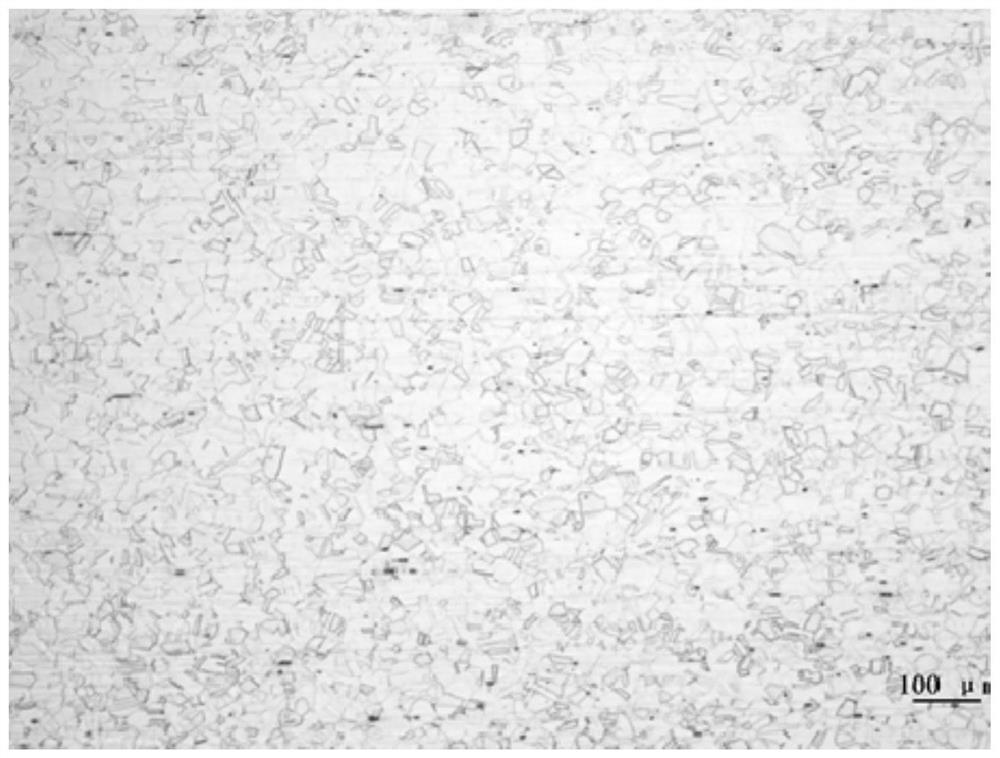

Image

Examples

Embodiment Construction

[0054] The invention will be further described below in conjunction with the examples.

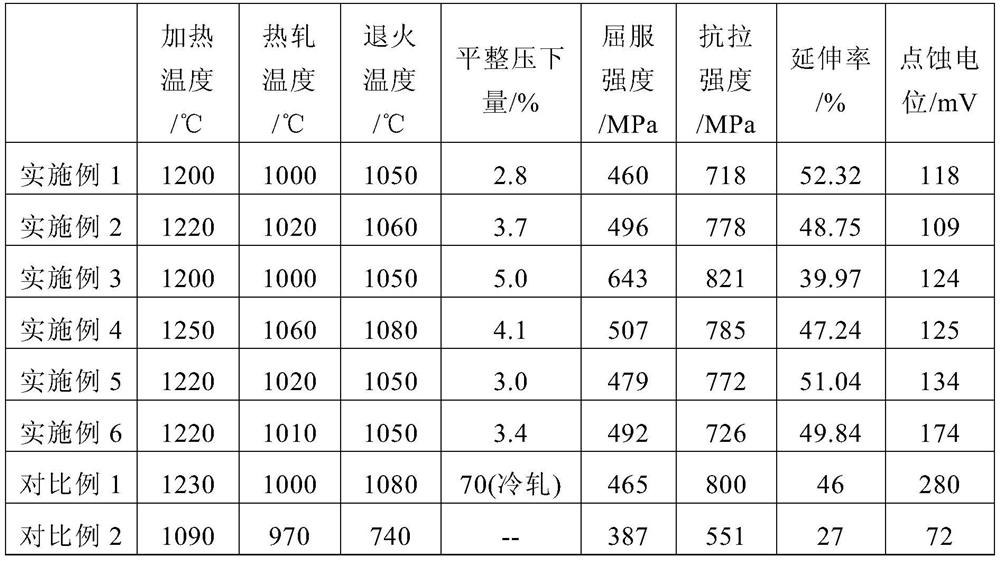

[0055] Examples of the composition of the austenitic stainless steel for economical rail vehicles of the present invention are shown in Table 1, and the balance is iron and inevitable impurities. The finished product properties are shown in Table 2.

[0056] The manufacturing method of austenitic stainless steel for economical rail vehicles of the present invention comprises the following steps:

[0057] 1) Smelting and continuous casting

[0058] According to the chemical composition, through electric furnace, AOD, VOD three-step smelting or electric furnace, AOD two-step smelting, after continuous casting to obtain casting billet;

[0059] 2) Hot rolling

[0060] The heating temperature of hot rolling is 1200~1280℃, and the heating time is determined by the thickness of the ingot or slab, which is determined according to the principle of 1~2min / mm; the final rolling temperature is 980...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com