Separation kettle in supercritical CO2 anhydrous dyeing and finishing equipment

A separation kettle and supercritical technology, applied in the field of separation kettles, can solve the problems of increasing the difficulty of color change production, restricting the development of fluid dyeing and finishing technology, etc., to solve the needs of color change and function change, and to facilitate repeated applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

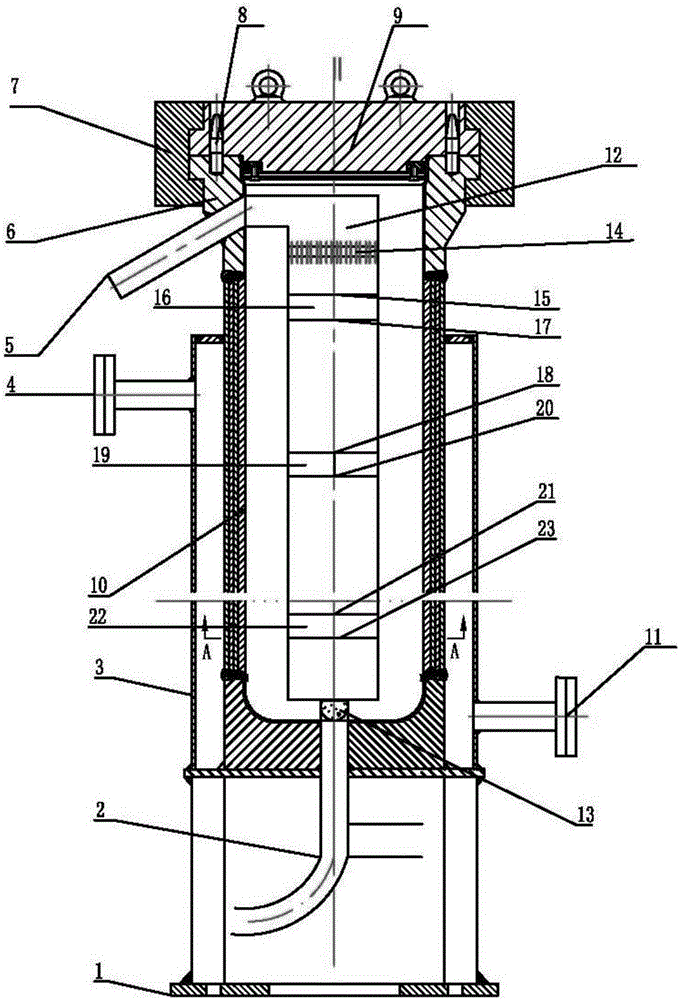

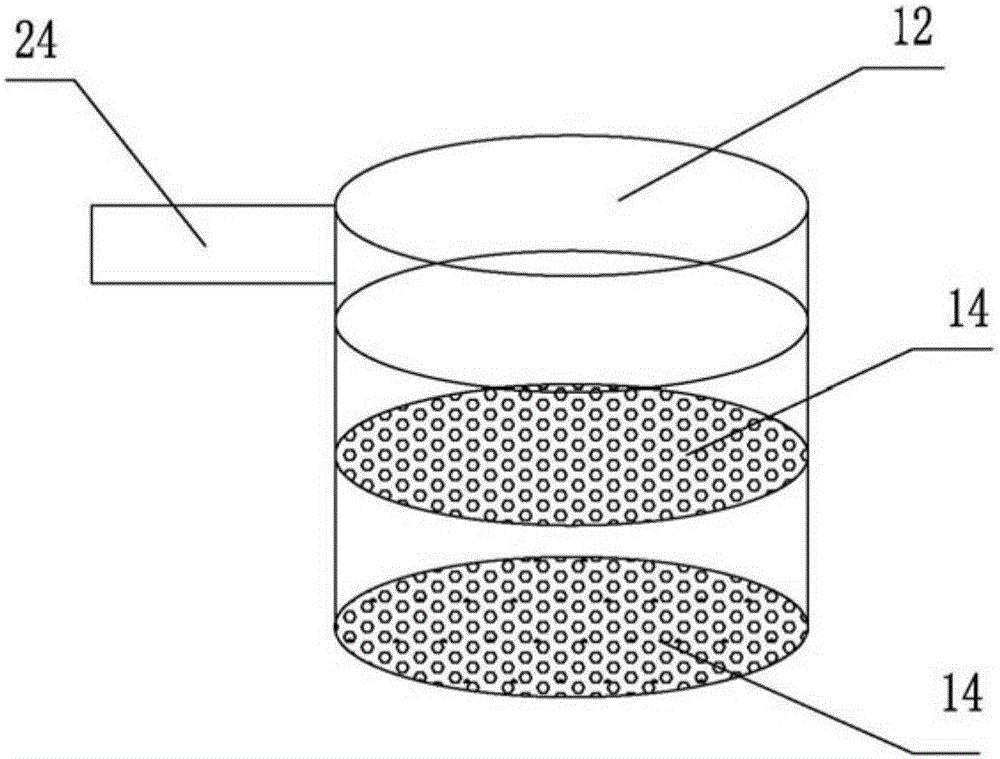

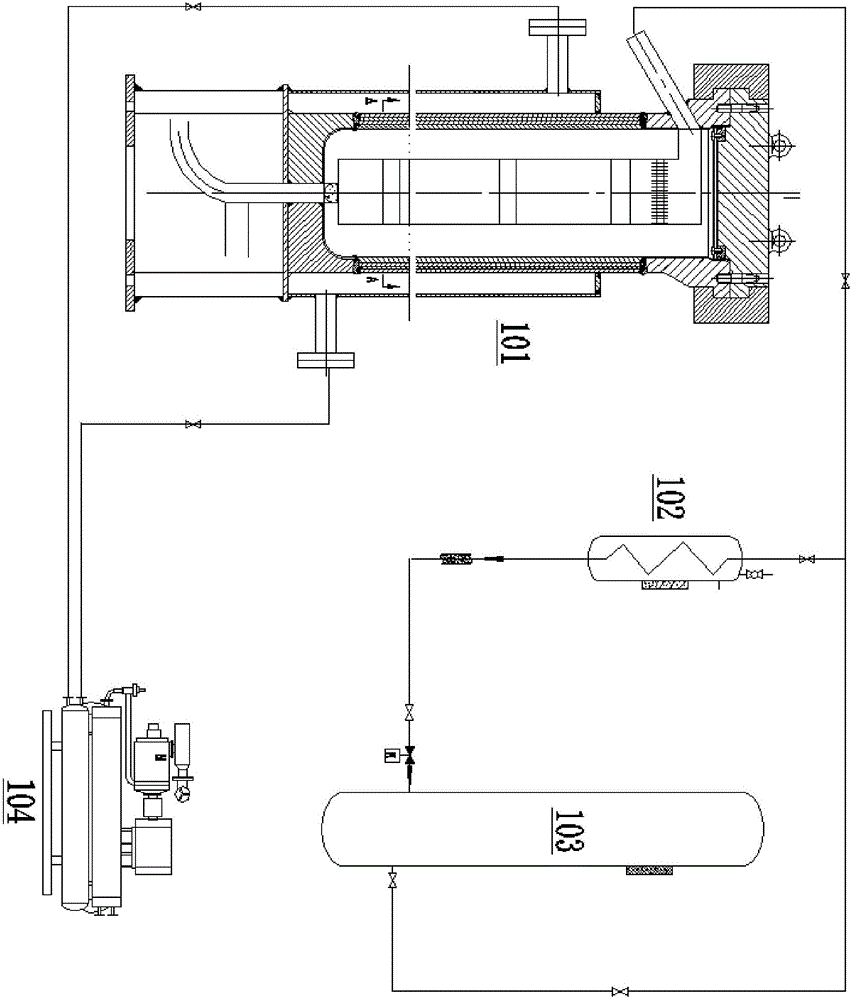

[0031] Such as figure 1 As shown, a supercritical CO 2A separation kettle in an anhydrous dyeing and finishing equipment, the separation kettle includes multiple membrane separators, and the multiple membrane separators include supercritical CO 2 There are three separation units in the channel for fluid circulation, and the separation unit is composed of an adsorption membrane, a gas-solid separation membrane, and a separation chamber formed between the adsorption membrane and the gas-solid separation membrane from top to bottom;

[0032] The top of the multi-membrane separator is provided with a telescopic movable cover 12, which is connected to the CO of the separation kettle. 2 The fluid outlet 5 is connected; the bottom of the multi-membrane separator is provided with a filter valve 13, and the filter valve 13 is connected to the CO of the separation tank. 2 Fluid inlet 2 connection. Wherein, the aperture of the sieve tray of the uniform gas channel 14 is 0.05mm; the ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com