Single-force-source tipper for steel production

A technology for dumping devices and steel, which is applied to furnaces, lighting and heating equipment, furnace components, etc., can solve problems such as labor and labor, and achieve the effect of solving manual feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

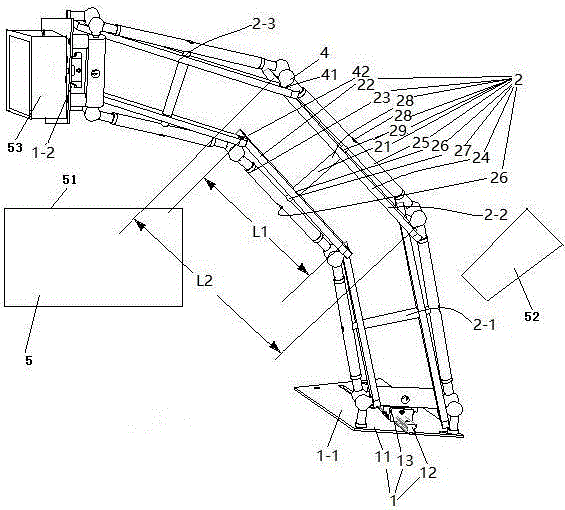

[0024] Embodiment one, see figure 1 , a single power source dumping device for iron and steel production, including a furnace 5 with a raw material inlet at the top, a raw material input pipe 52, a connecting seat assembly 1 and an arm 2.

[0025] The top of the melting furnace 5 is provided with a raw material inlet 51 .

[0026]There are two connecting seat assemblies 1. The two connecting seat assemblies 1 are respectively the first connecting seat assembly 1-1 and the last connecting seat assembly 1-2. Both the first connecting seat assembly 1-1 and the last connecting seat assembly 1-2 include a fixed seat 11, a slide rail 12 arranged on the fixed seat and a movable seat 13 slidably connected to the slide rail. The first connecting seat assembly 1-1 also includes a driving mechanism for driving the movable seat to slide on the slide rail (the driving mechanism is not shown in the figure), and the driving mechanism is an air cylinder. The first connecting seat assembly...

Embodiment 2

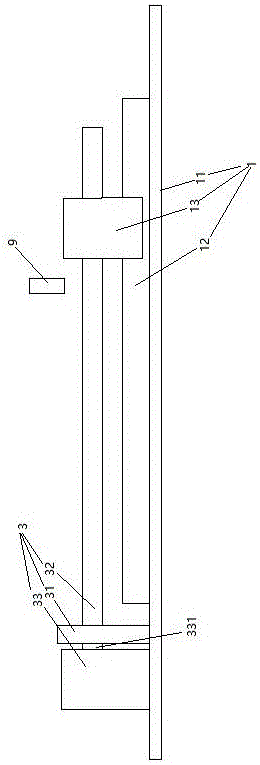

[0033] Embodiment two, the difference with embodiment one is:

[0034] see figure 2 , the driving mechanism 3 provided on the first connecting seat assembly 1 includes a screw rod 32 and a driving motor 33 . One end of the screw rod 32 is threaded on the movable seat 13, and the other end is fixed together with the power output shaft 331 of the driving motor through a connector. A bearing seat 31 supporting the screw rod 32 is also provided on the fixing base 11 . The connecting seat assembly 1 is also provided with a filler nozzle 9 for filling oil toward the slide bar 12 . During use, the screw mandrel 32 is driven to rotate by the driving motor 33 , and the screw mandrel 32 drives the movable seat 13 to slide on the slide rail 12 .

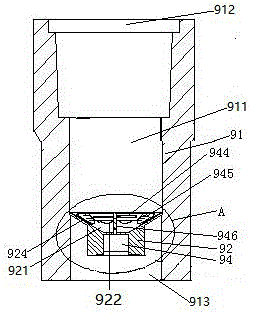

[0035] see image 3 , The filler nozzle 9 includes a filler nozzle body 91 and a filter plate 92 . The fuel nozzle body 91 is a cylindrical structure extending in the vertical direction. A flow channel 911 is provided in the fuel nozzle ...

Embodiment 3

[0039] Embodiment three, the difference with embodiment two is:

[0040] see Image 6 , The driving mechanism is also provided with a control unit 37 and an overload detection switch 38 . The screw rod 32 is provided with a driven helical gear 322 and retaining springs blocking both ends of the driven helical gear 322 to prevent the driven helical gear 322 from moving axially. . A driving helical gear 332 is slidably sleeved on the power output shaft 331 of the driving motor in the axial direction. The driven helical gear 322 meshes with the driving helical gear 332 . A prism section 333 is provided on the power output shaft 331 of the driving motor. The driving helical gear 332 is provided with polygonal holes matching the prism segments. The driving helical gear 332 is axially movably sleeved on the power output shaft 331 of the drive motor and cooperates with the prism section 333 through the polygonal hole to transmit force when sliding and rotating. Both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com