A diaphragm positioning and clamping device

A technology for positioning, clamping and diaphragms, applied in the field of wind tunnel testing, can solve the problems of affecting the operation of film breaking in wind tunnels, complicated operations, and the failure of clamping and positioning of diaphragms to achieve the expected effect, so as to improve the accuracy of connection positioning and sealing. The effect of performance, simple equipment operation and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

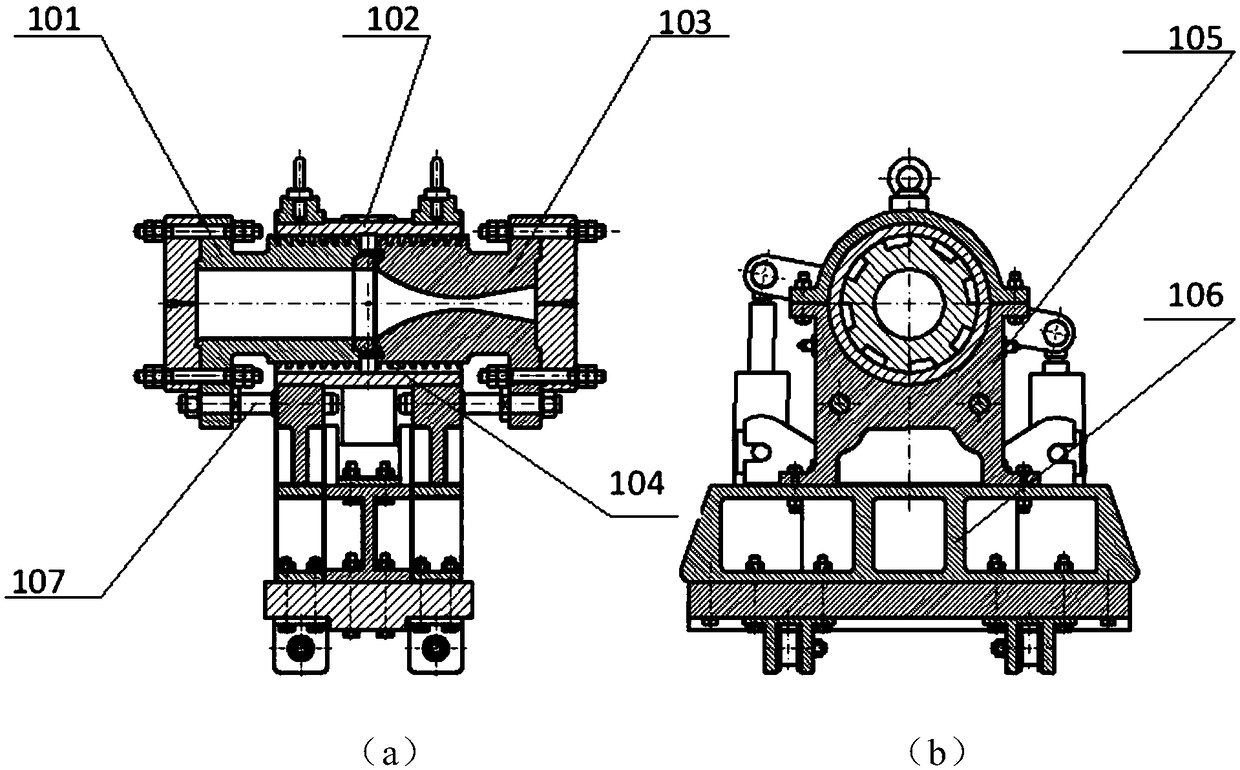

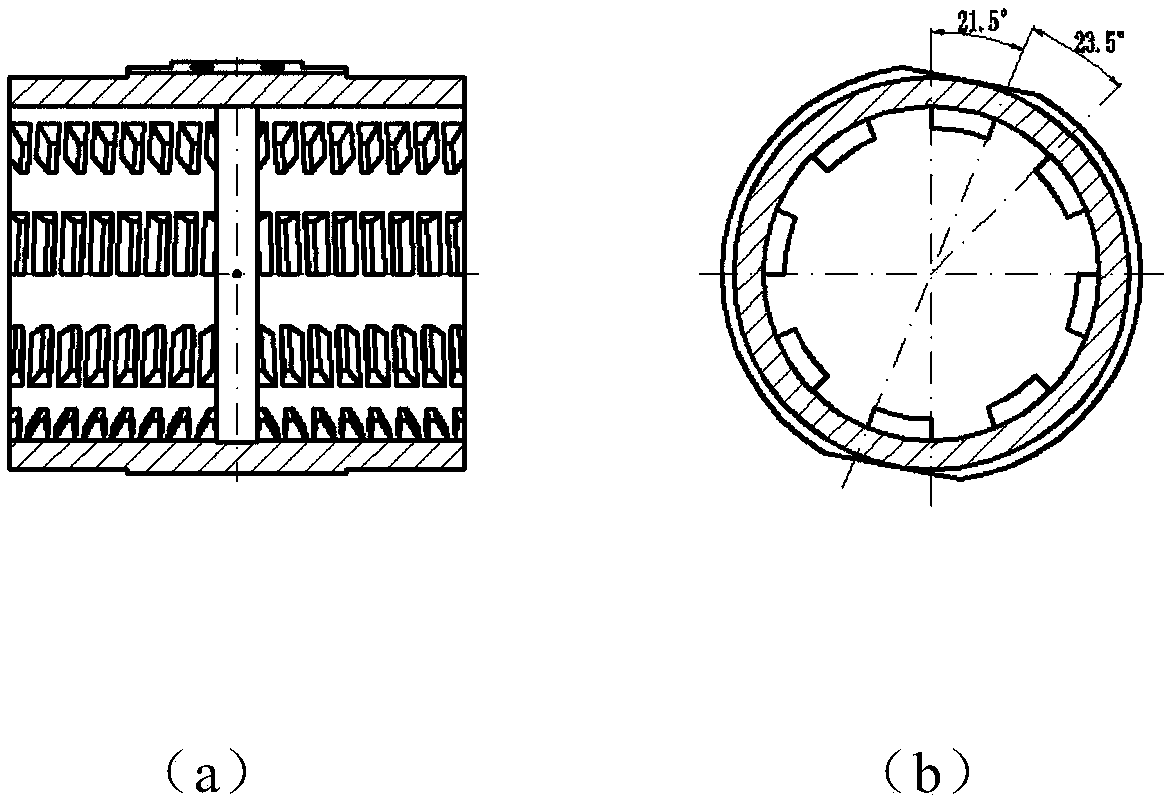

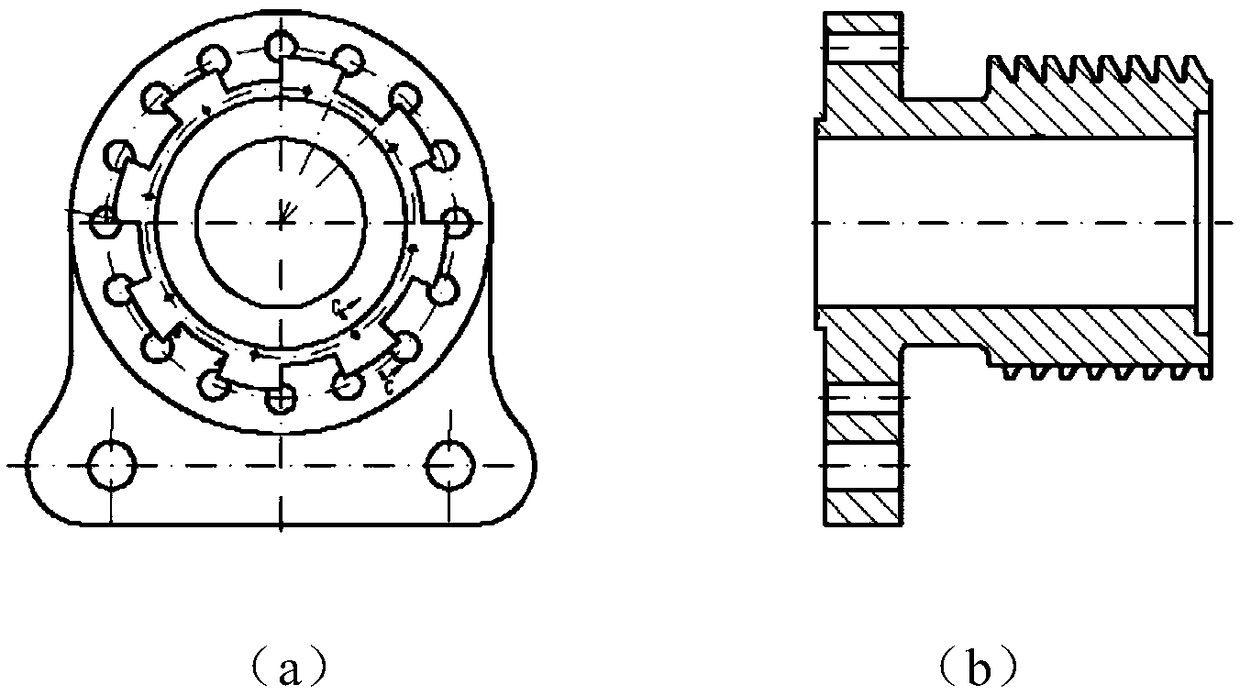

[0035] figure 1 Shown is an automatic clamping diaphragm device using slotted thread engagement. According to the aerodynamic design requirements of the wind tunnel, a diaphragm needs to be installed before the entrance of the shock tube and the nozzle of the high-energy pulse wind tunnel, and at the same time ensure the accurate positioning of the diaphragm. and seal.

[0036] The slotted nut 102 has two threaded holes in the left and right directions, the external threads of the slotted left-handed screw rod 101 and the slotted right-handed screw rod 103, which are respectively reserved for meshing threads, and the remaining parts are processed into long grooves to ensure the opening. The slotted left-handed screw 101 and the slotted right-handed screw 103 can be smoothly inserted and pulled out from the threaded hole of the slotted nut 102 to realize the replacement of the diaphragm. The function of the long groove is to facilitate the slotted left-handed screw 101 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com