Heat radiating device for ferrite switch

A heat sink, ferrite technology, applied in electrical switches, electrical components, circuits, etc., can solve the problem of heat dissipation of high-power ferrite switches, and achieve the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

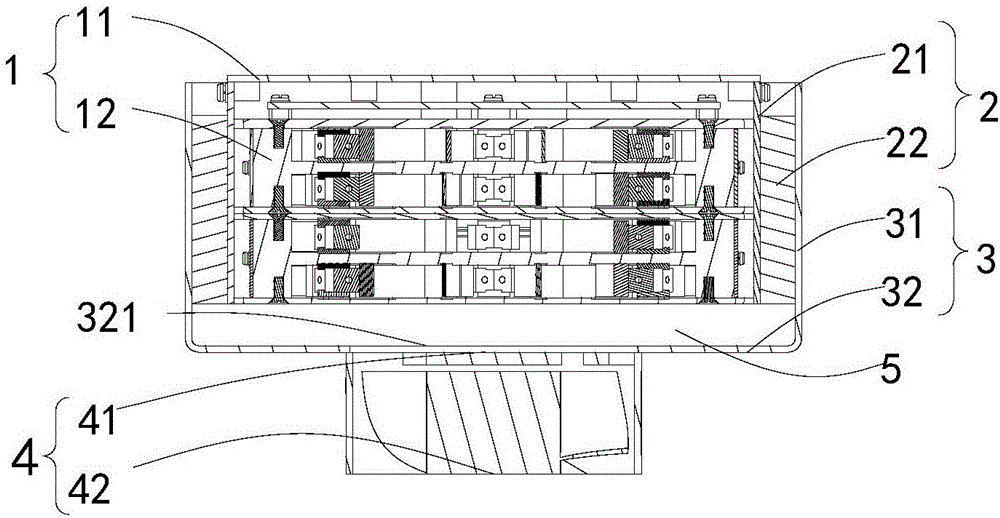

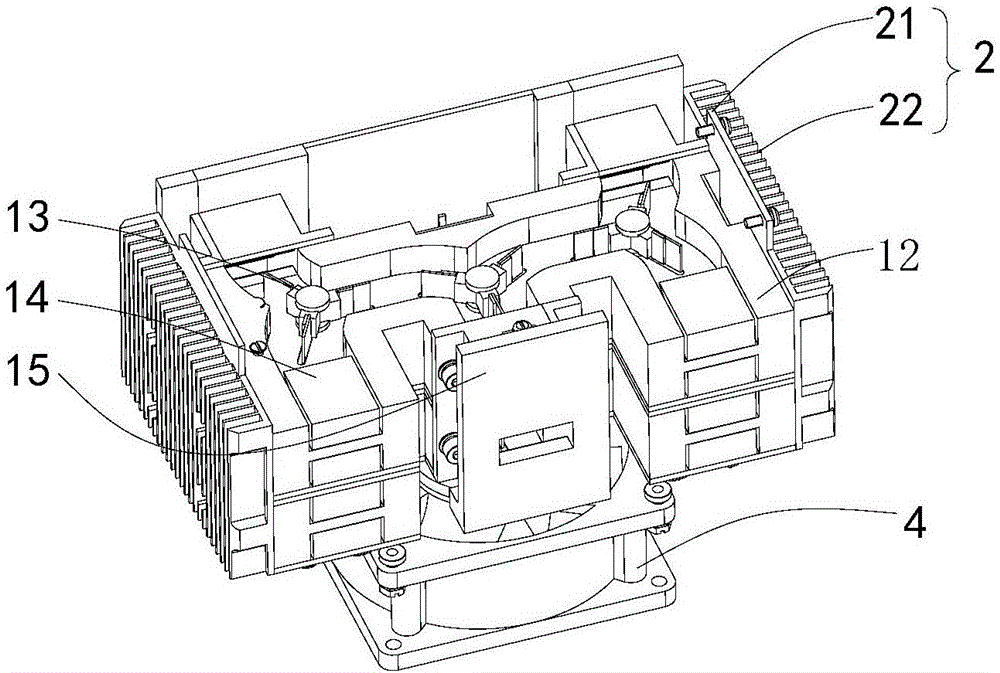

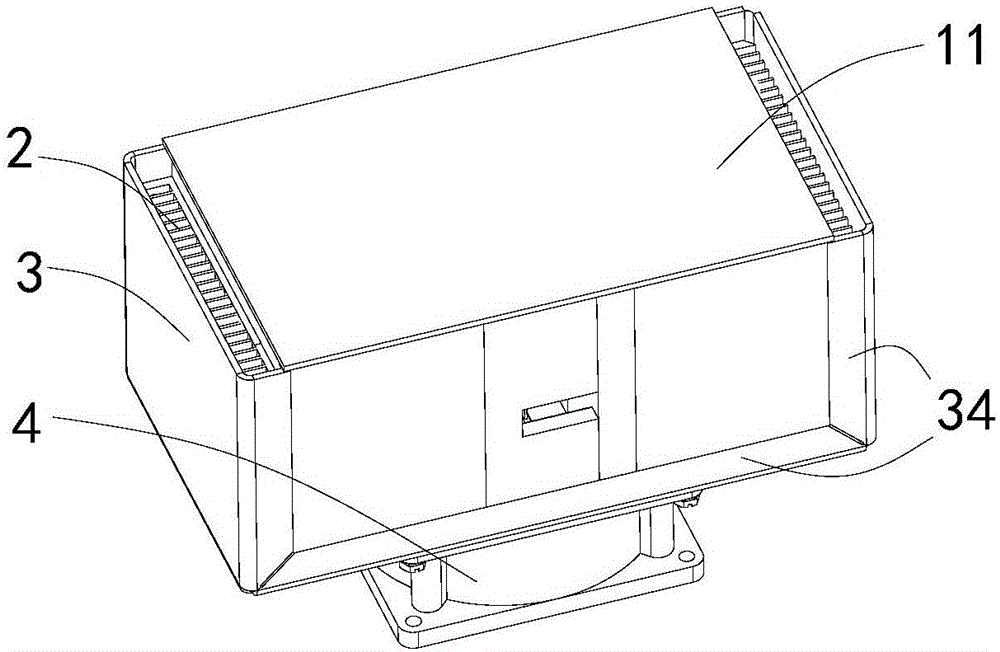

[0021] Please also see Figure 1 to Figure 3 , The present invention provides a heat dissipation device for a ferrite switch, including a ferrite switch 1, a heat dissipation plate 2, an air duct cover plate 3 and a fan 4. The cooling plate 2 is located on the outer walls of both sides of the ferrite switch 1 . The top of radiator plate 2 can be bolted with cover plate 11 (as figure 1 As shown), the heat dissipation plate 2 can also be directly pasted or bolted to the outer walls on both sides of the housing 12. The air duct cover plate 3 is arranged on the outer side of the heat dissipation plate 2 and has a U-shaped structure. The fan 4 is connected to the lower end of the opening 321 provided at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com