Mechanical supercharging and decompression self-locking device and supercharging and decompression self-locking method thereof

A self-locking device and mechanical technology, applied in the field of liquid injection machines, can solve the problems of non-continuity, high installation and maintenance costs, large cylinders or hydraulic cylinders, etc., to reduce the use of solenoid valves and pipelines, and ensure equipment stability , Low installation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

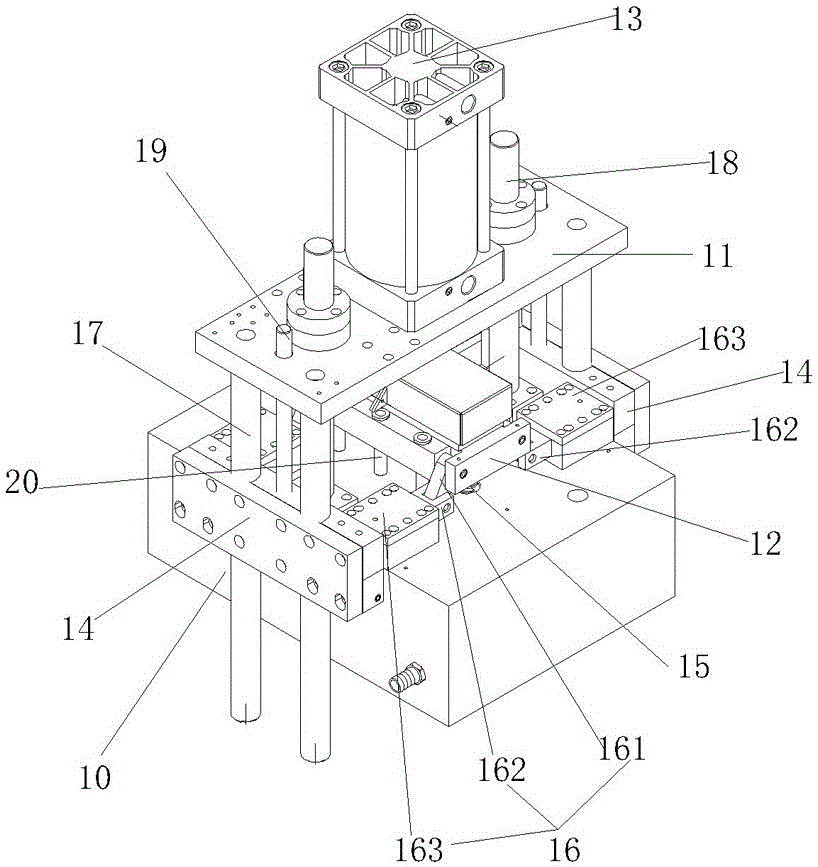

[0041] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0042] see figure 1 , the mechanical increasing and reducing pressure self-locking device provided by the present invention includes a box body 10, a fixed plate 11, a connecting plate 12, a cylinder 13 and two clamping blocks 14; the cylinder 13 is installed on the fixed plate 11, and the cylinder 13 is pushed through The rod is connected to the connecting plate 12 by driving, and the bottom end of the connecting plate 12 is provided with a spring 15 that can be connected to the top of the box body 10; two clamping blocks 14 are fixedly connected to both sides of the fixed plate 10, and the two A clamping space that allows the box body 10 to move up and down is formed between the tight blocks 14; the four corners of the connecting plate 12 are pivotally connected with a self-locking mechanism 16;

[0043] Drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com