Asynchronous machine control method based on linkage compensation

A technology for asynchronous motors and control methods, applied in motor control, AC motor control, control systems, etc., can solve problems such as motor parameter deviation, control performance degradation, and slow torque response, achieving small motor output torque fluctuations, Improved response speed and high control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

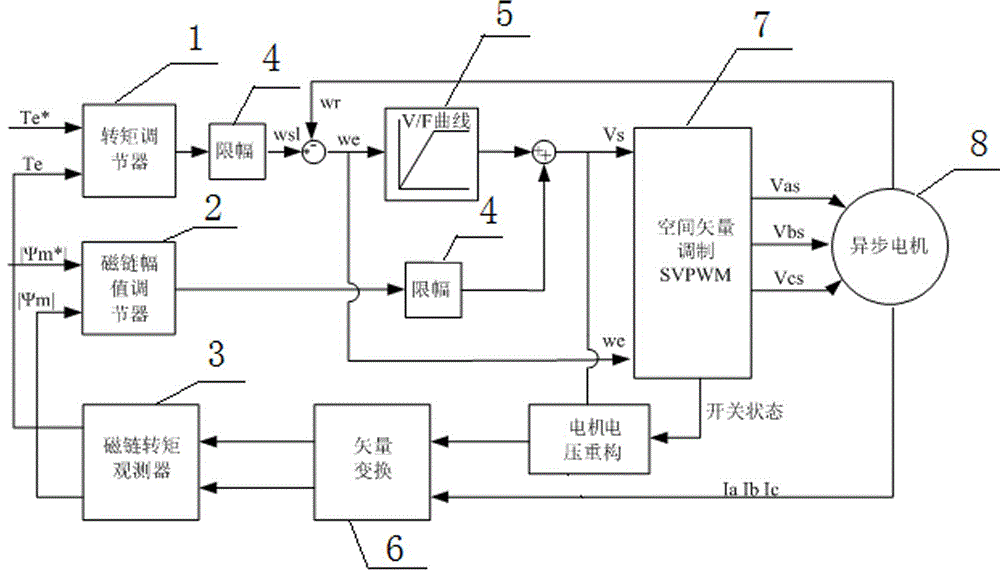

[0020] With reference to accompanying drawing, a kind of asynchronous motor control method based on flux linkage compensation, its steps are:

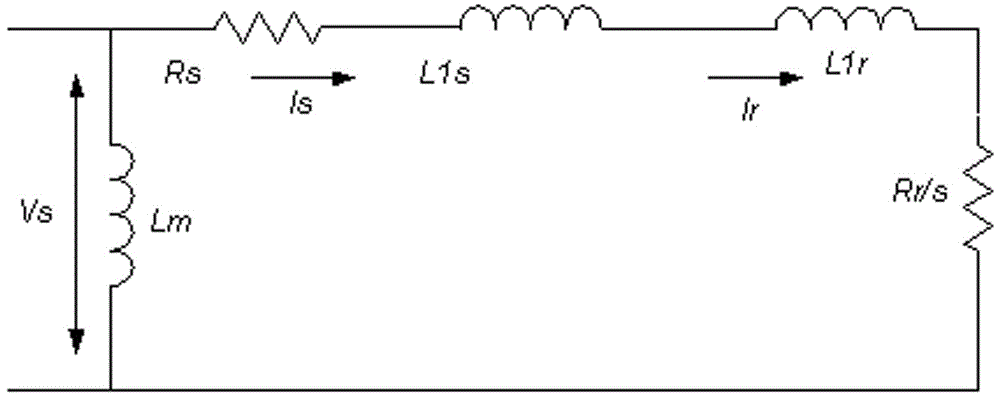

[0021] Step 1. Input the DC voltage, motor current, motor voltage, and motor angular frequency to the flux torque observer 3 through the vector transformation 6, and the flux torque observer 3 calculates according to the asynchronous motor 8 static coordinate system model and the above input parameters The torque of the motor and the amplitude of the air gap flux linkage are obtained, and the voltage of the motor is reconstructed according to the DC voltage and the switch state of the inverter;

[0022] Step 2. Send the calculated actual motor torque and air-gap flux linkage amplitude to the torque regulator 1 and the flux linkage regulator 2. After limiting the amplitude 4, the slip frequency given value and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com