Viscose electrical heating system capable of being repaired

A technology of electric heating and glue, which is applied in the direction of heating element shape, etc., can solve the problems of inability to ensure the contact of the long metal rod of the heating wire, the scrapping of the reworkable glue-type electric heating system, and the aging of the insulating heat transfer glue. , to achieve the effects of not easy attenuation of power, saving raw materials, and simple and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The reworkable adhesive type electric heating system of the present invention will be further described below in conjunction with the accompanying drawings.

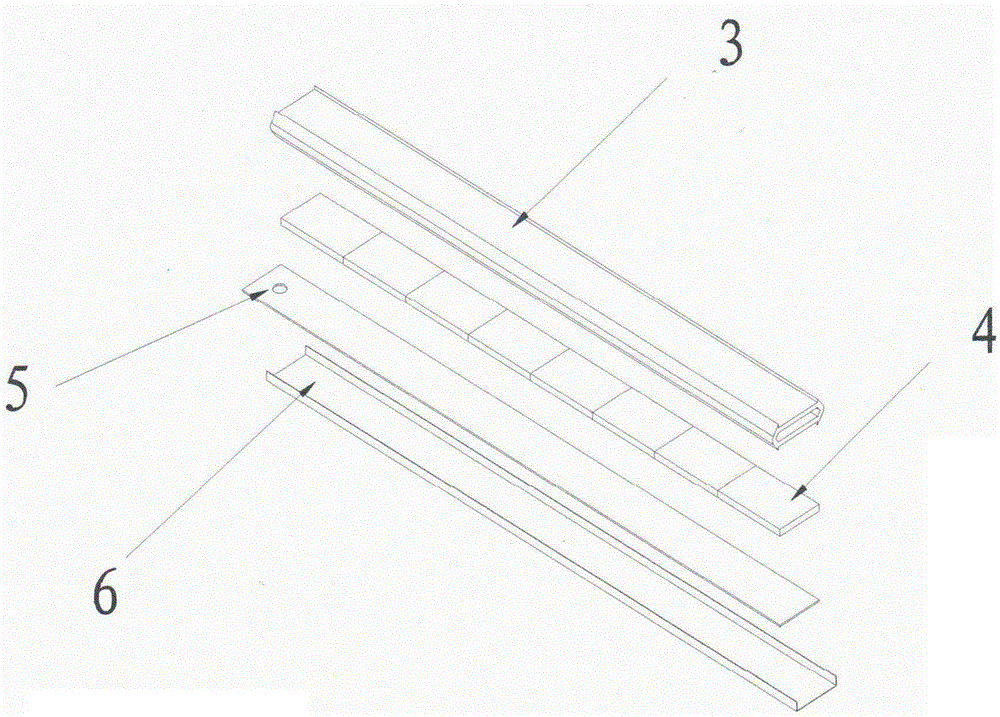

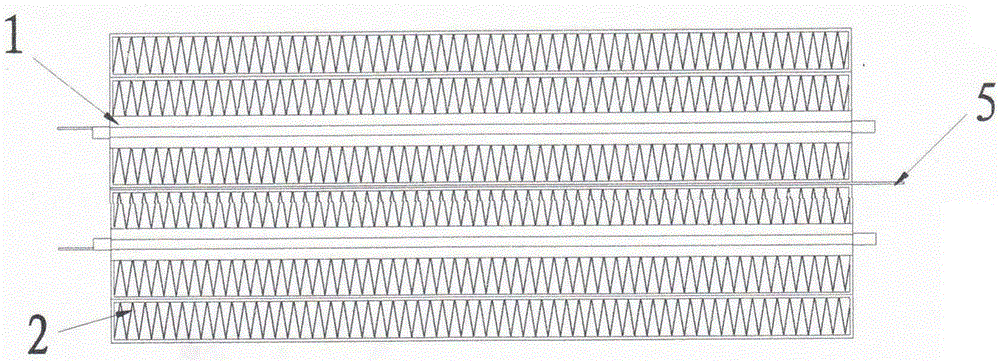

[0011] Such as figure 1 and figure 2 As shown, the heating wire 1 includes a concave heat-conducting insulating layer 6, a conductive rod 5 is placed in the concave surface, and several heating wires 4 are arranged on the conductive rod 5, and then they are plugged into the shell 3, the two sides of the casing 3 are pressed mechanically to make the internal structure compact and in good contact, forming a complete heating wire 1.

[0012] Such as figure 1 As shown, the heating wire 4 is a sheet structure, and its quantity is determined according to actual needs.

[0013] The shell 3 is in the shape of a rectangular flat tube, with a long square hole for assembly in the middle, and positioning grooves matching the long metal rod 2 on the two outer sides. The length of the shell 3 is the same as the length of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap