Accelerating tube

A technology of accelerating tube and accelerating cavity, applied in the field of accelerating tube, can solve the problems of reducing the stability and reliability of the accelerating tube, increasing the difficulty of processing technology, etc., so as to reduce the baking and exhaust process, reduce the risk of ignition, and save R&D and manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

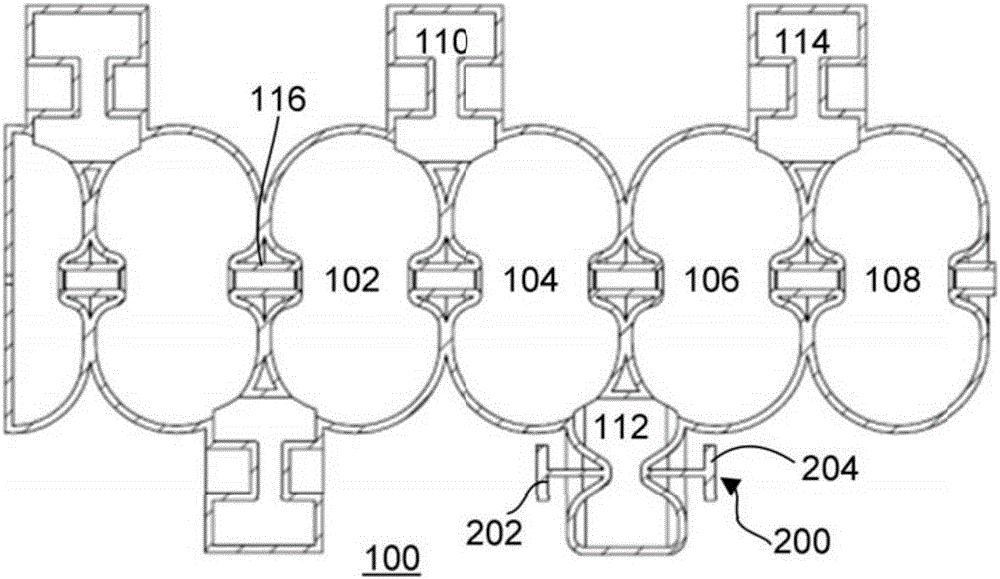

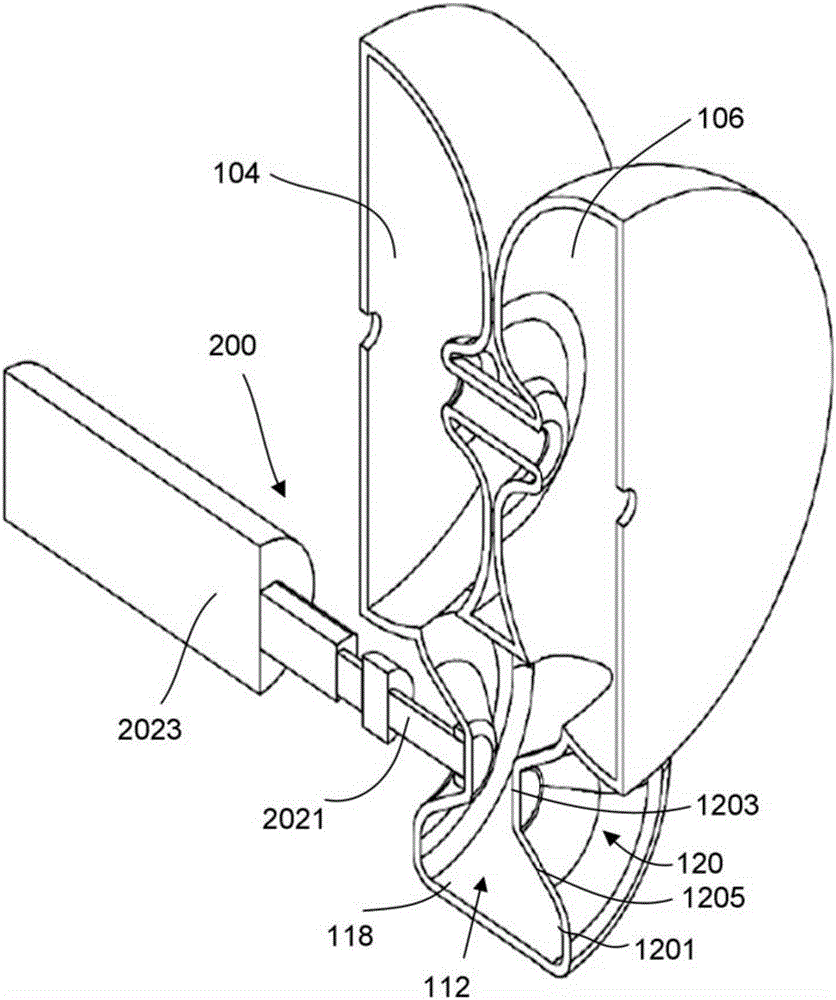

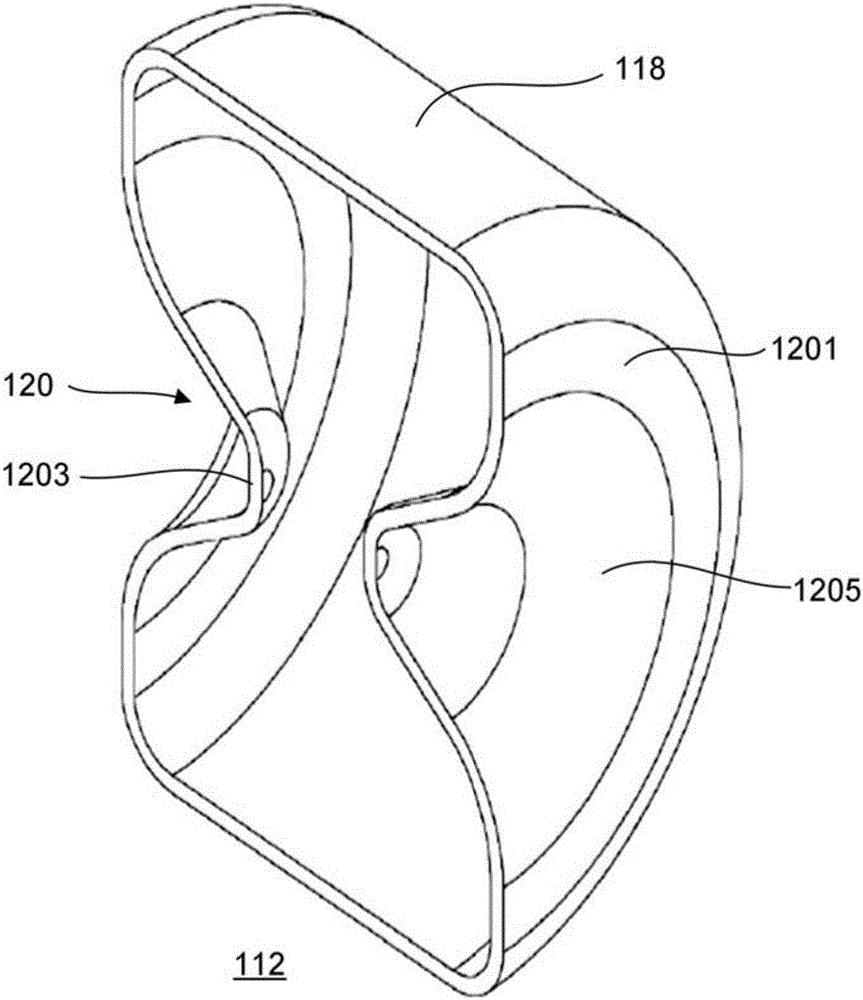

[0028] Such as Figure 1-3 As shown, an accelerating tube 100 is disclosed. The accelerating tube 100 is exemplarily an edge-coupled standing wave accelerating tube, which includes a plurality of accelerating cavities 102, 104, 106, 108 and adjacent accelerating cavities 102, 104, 104, 106, 106, 108 coupling edges Coupling cavities 110 , 112 , 114 . A beam channel is defined between the accelerating chambers 102 , 104 , 106 , 108 by a drift tube 116 . As shown in the figure, in this exemplary embodiment, the side coupling cavities 110, 114 adopt a common design, that is, the inside of the side coupling cavities 110, 114 have an upstream nose cone and a downstream nose cone opposite to each other. Each nose cone divides each side couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com