Non-guide porous punching die

A technology of porous punching and die, applied in the direction of perforating tools, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient use and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

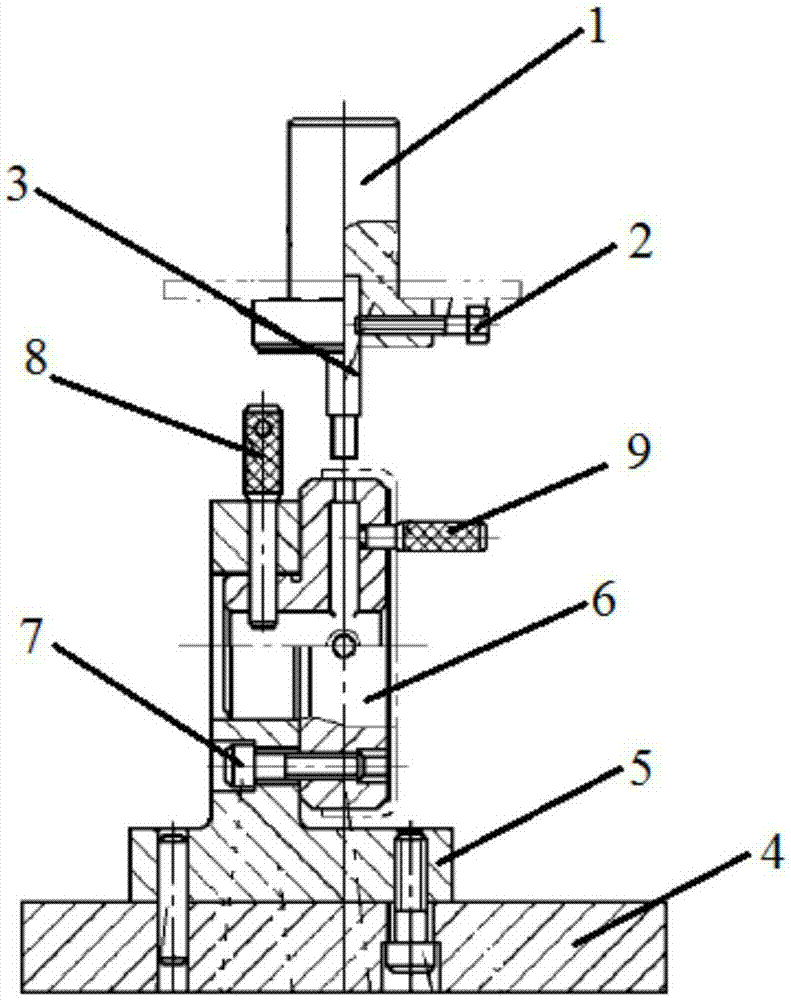

[0015] Example 1 : A non-guided porous punching die includes an upper die part and a lower die part.

[0016] The upper die part includes a circular universal punch 1 connected to an external press, a punch lock bolt 2 and a punch 3 fixed at the bottom of the punch, the punch lock bolt 2 is vertical to the punch 3, and the end passes through the punch The through hole on the head 1 tightens the punch 3 and fixes the punch 3 on the bottom of the punch 1.

[0017] The lower mold part includes a base 4, a support 5 fixed on the base 4 by a cylindrical pin, and a die 6 fixed to the side of the support 5 suspended in the air. The die locking bolt lock 7 is fixed on the support 5, the position of the die 6 is positioned by the die locating pin 8 arranged on the side of the die 6, and the side of the die 6 is also provided with a punching pin that matches the bottom surface of the punching piece. The positioning hole matched by the cutting hole is provided with a stamping positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com