A double-roller unilateral movable large chain and its application

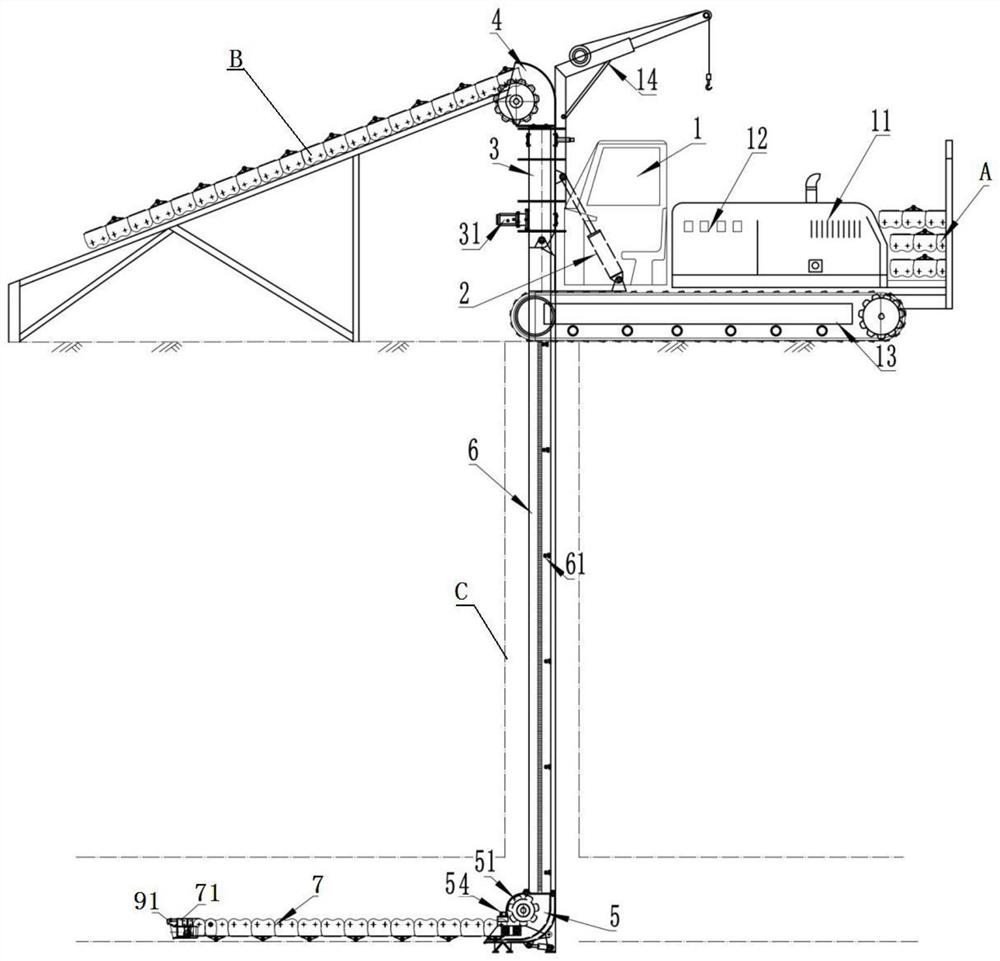

A chain and active technology, which is applied in the field of conveying or separating materials excavated by dredging or excavation, can solve problems such as the hidden danger to the life safety of operators, the limitation of the diameter of the robot, and the health hazards of operators, so as to improve the dredging effect. effect, ensuring safety, reducing the effect of re-destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

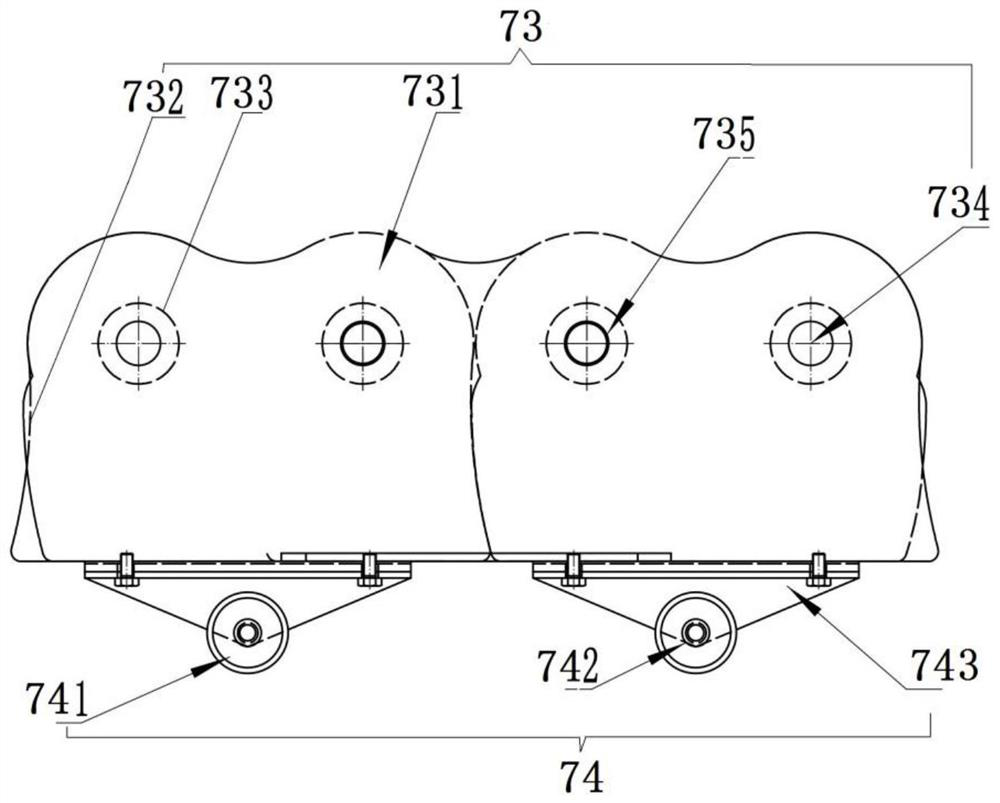

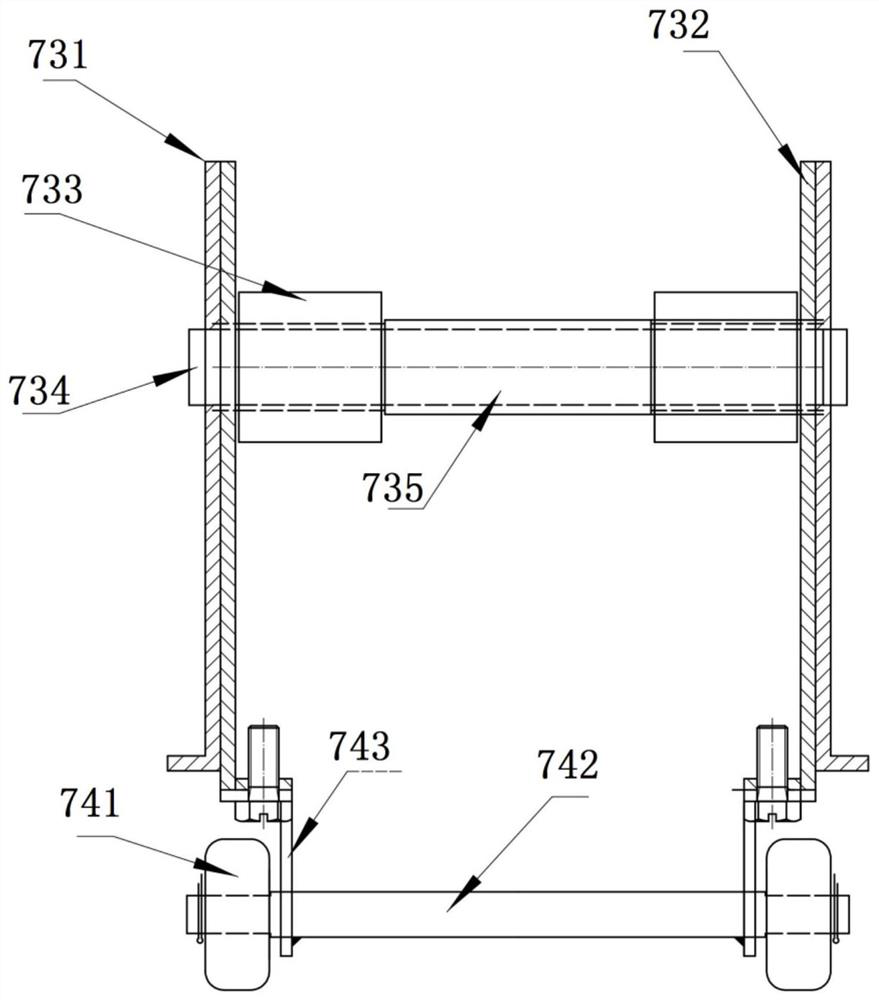

[0042] In this embodiment, a double-roller unilateral movable large-scale chain combines figure 1 and figure 2 , comprising a chain mechanism 73 and a traveling mechanism 74, the chain mechanism 73 comprising an outer chain plate 731, an inner chain plate 732, the outer chain plate 731 being mounted on the outside of the inner chain plate 732 through a shaft pin 734; the traveling mechanism 74 comprising a roller 741 and a support Plate 743, support plate 743 is fixed on inner chain plate 732 bottoms, and roller 741 is movably installed on support plate 743 bottoms, and can do rolling motion at support plate 743 bottoms.

[0043] The above scheme is a single-plate structure, and it can also be set as a double-plate structure during operation, that is: combined figure 2 , there are two inner chain plates 732, and the shaft pin 734 is located between the two inner chain plates 732; two outer chain plates 731 are provided, and the two outer chain plates 731 are respectively in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com