Double-laser-welding integrated welding head

An integrated, welding head technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of non-adjustable shielding gas shielding position, difficult shielding welding, and cumbersome teaching process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

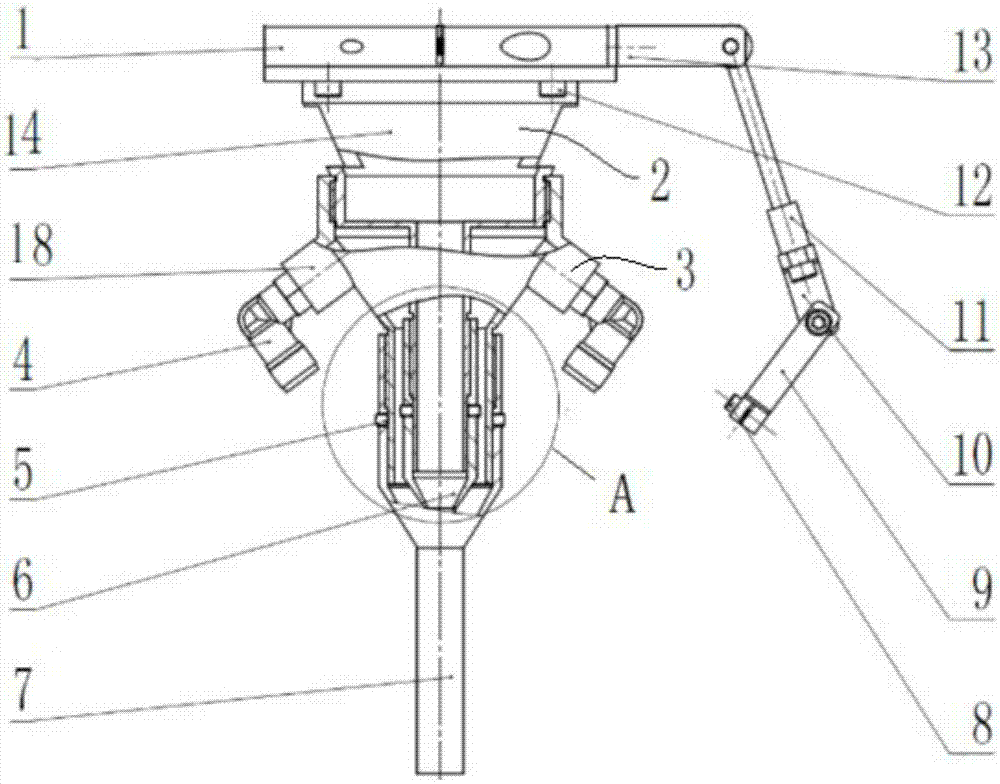

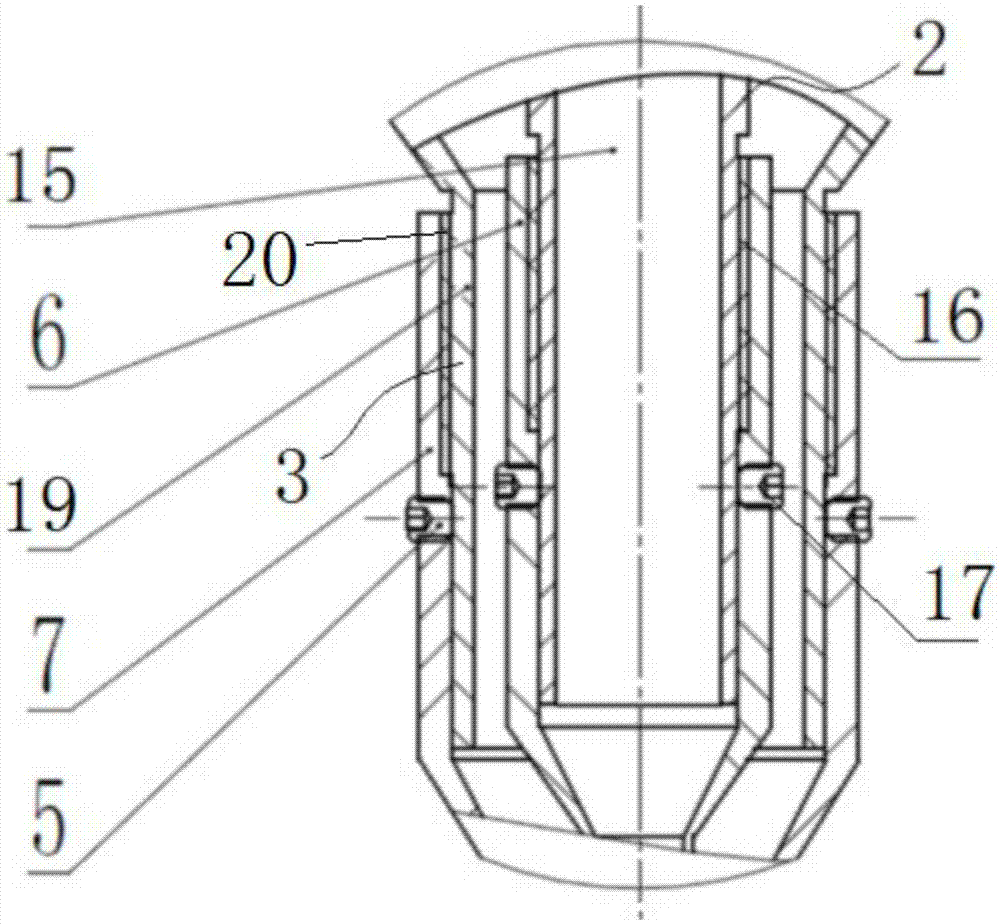

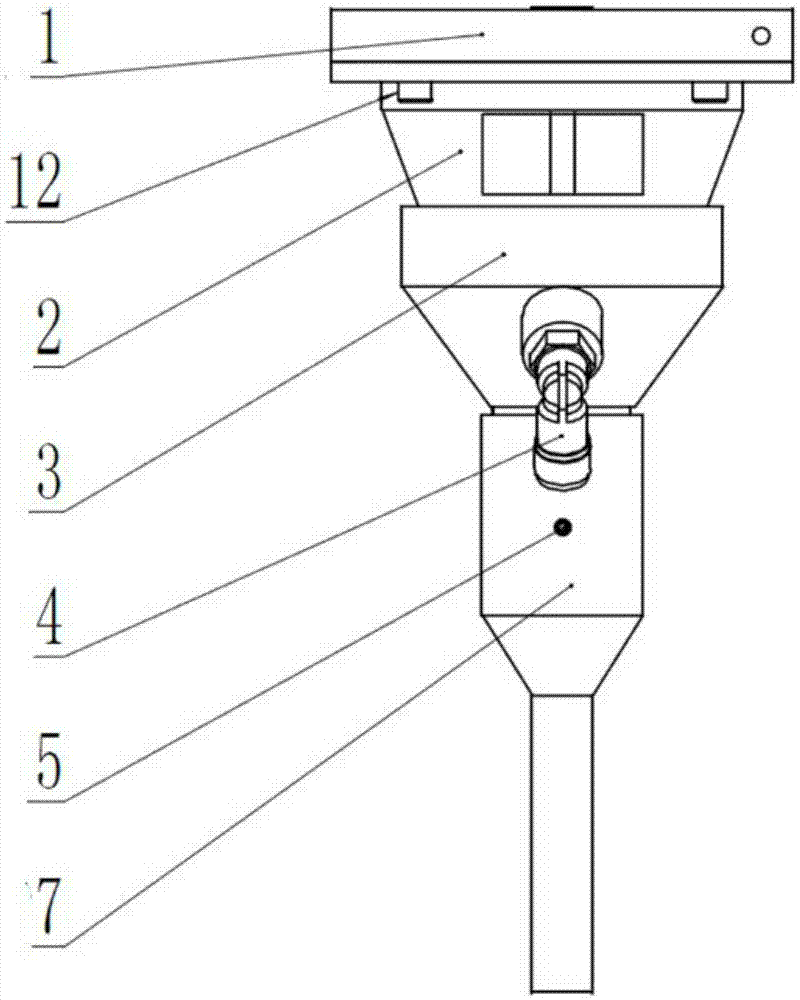

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1~3 As shown, the present invention includes a laser head interface 1, a nozzle base 2, an outer base 3, an L-shaped threaded joint 4, an inner core sleeve 6, an outer connecting sleeve 7 and an auxiliary laser frame assembly, wherein the laser head interface 1 is connected to the laser The interference fit of the head is fixed on the laser head, and the nozzle base 2 is installed on the lower side of the laser head interface 1, such as Figure 1~2 As shown, the nozzle base 2 includes a base body 14 and a hollow connecting shaft 15, the base body 14 of the nozzle base 2 is fixedly connected with the laser head interface 1 by screws 12, and the nozzle base The base body 14 of 2 and the laser head interface 1 are positioned through the joint, and the connecting shaft 15 is vertically arranged on the lower side of the base body 14, as f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap