Excellent superimposed refined energy-saving quick smashing machine

A kind of high-speed crusher and high-quality technology, which can be used in household appliances, applications, kitchen utensils, etc. It can solve the problems of limited use, single function, and simple structure, and achieve the effect of exquisite design structure, superior technical performance, and overcoming design lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

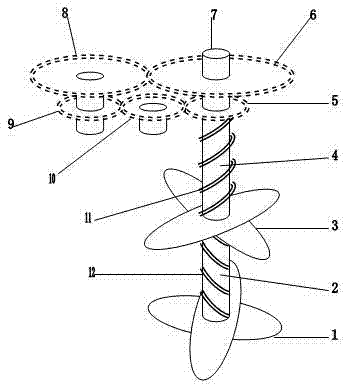

[0020] Connect the main drive shaft 7 of the high-quality superimposed, refined, energy-saving and fast crushing machine of the present invention to an external related drive and start the main drive shaft 7. The main drive shaft 7 drives the main gear 6 and the main shaft rod 2 synchronously, and the main shaft rod 2 drives respectively The main stack knife 1 and the main stirrer 12 work forward. At the same time, the main gear 6 drives the auxiliary gear 8, and the auxiliary gear 8 drives the left gear 9, the left gear 9 drives the middle left wheel 10, and the middle gear 10 drives again The right gear 5 and the right gear 5 drive the counter shaft 4, and the counter shaft 4 then drives the auxiliary stack knife 3 and the auxiliary stirrer 11 to work in reverse. Because the gear diameter and index are different, the forward and reverse torques and speeds of the main gear 6 and the right gear are also different, and the main stack knife 1, the main stirrer 12, and the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com