Automated inspecting and screening line for anti-pressure performance detection of capacitor shells

A technology of compressive performance and capacitors, applied in the field of capacitor testing, can solve the problems of high single product price, difficult shell quality, management and control, etc., to achieve the effect of fast testing, improve product quality, and enhance corporate image.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

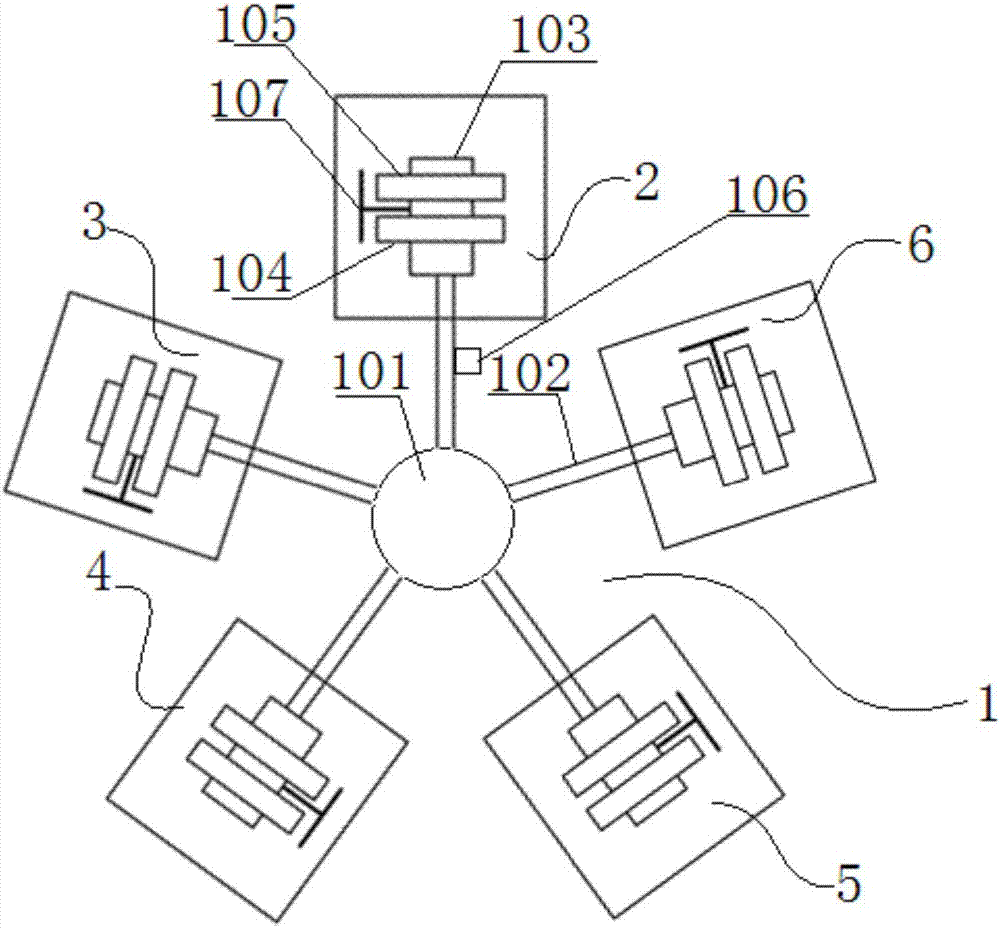

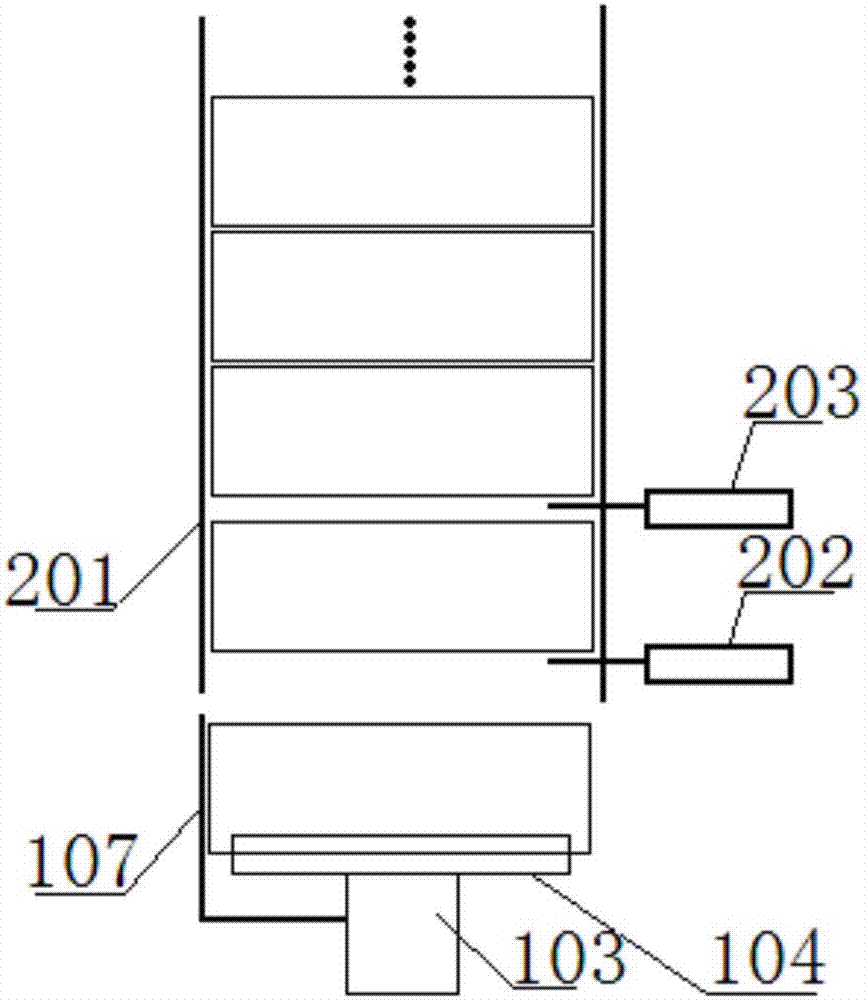

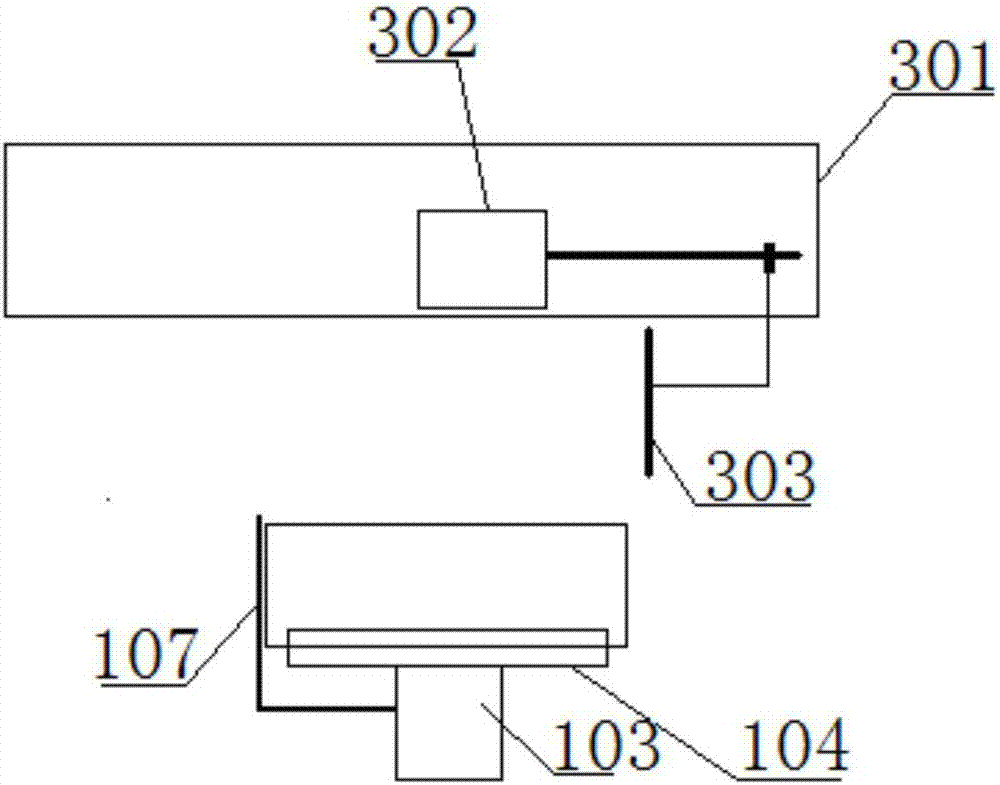

[0048] The automatic inspection and screening line used for the detection of the pressure resistance of capacitor shells can automatically feed, test, and inspect capacitor shells, and finally complete the classification and screening. The operation is fully automated and intelligent, without manual operation, and can effectively The appearance quality of capacitor products is controlled. The inspection and screening line includes a transfer mechanism 1, a feeding station 2, an end extrusion station 3, a side wall rolling station 4, a flaw inspection station 5 and a screening station 6.

[0049] The transfer mechanism 1 is used for the transportation of materials. The transfer mechanism 1 is provided with a central turntable 101, and the turntable 101 is provided with a power source to drive it to rotate. In order to ensure the stability when it stops, a braking mechanism can also be equipped. The turntable 101 is provided with a laterally extending side support bar 102 at int...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap