Patents

Literature

94results about How to "Comprehensive inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LTE cell overlapping coverage analysis method based on MR data

InactiveCN105828365APrecise positioningReasonable optimization suggestionsData switching networksWireless communicationData fileDistance analysis

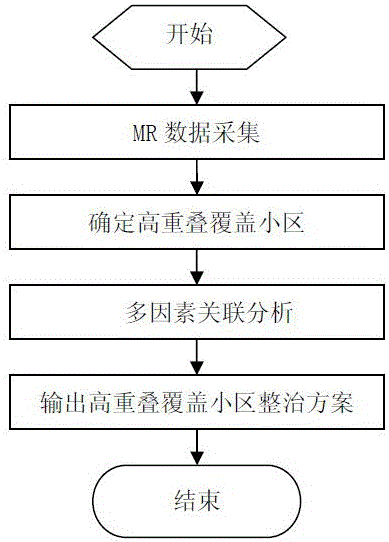

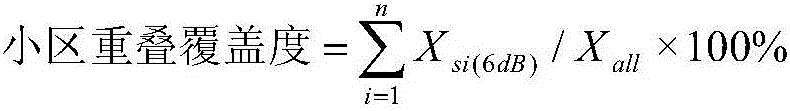

The present invention proposes a method for analyzing overlapping coverage of LTE cells based on MR data, including collecting MR data, obtaining LTE MR data files and cell information tables; Respectively form overlapping coverage adjacent cell pairs with the main cell, and calculate the weight of overlapping adjacent cell pairs according to the signal points of overlapping adjacent cells, sort and determine the priority of overlapping coverage cells and then screen them, and analyze the coverage distance of cells that have passed the weight screening to determine High overlapping coverage cells to be optimized; multi-factor correlation analysis, including weak coverage correlation analysis, useful signal proportion analysis and user concentration correlation analysis. The technical scheme of the present invention can more accurately locate problem cells, and can put forward more reasonable optimization suggestions, and can perform all-round inspection and troubleshooting of overlapping coverage cells.

Owner:WUHAN HONGXIN TECH SERVICE CO LTD

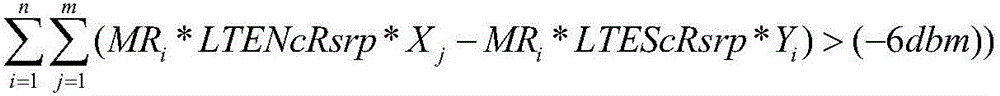

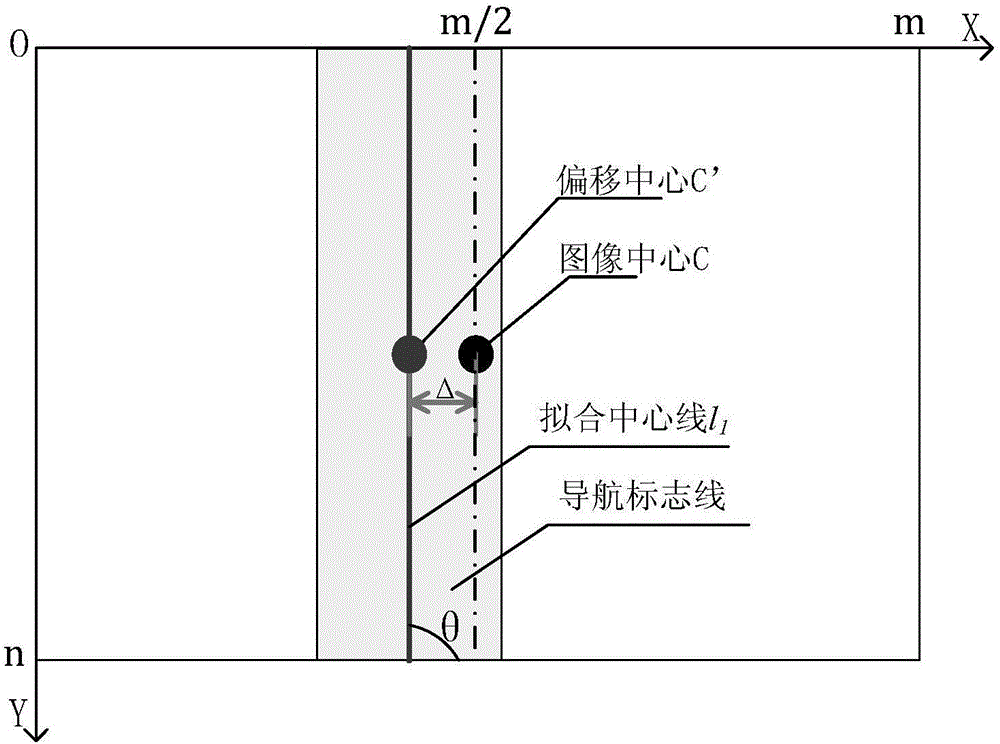

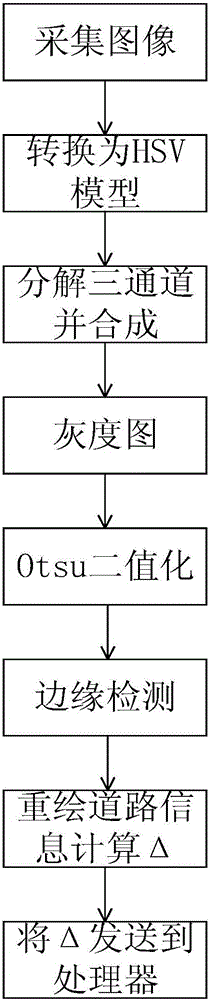

Vision-based navigation and positioning control method for transformer substation inspection robot

ActiveCN105700532AComprehensive inspectionStrong anti-interferencePosition/course control in two dimensionsVehiclesTransformerSimulation

The invention discloses a vision-based navigation and positioning control method for a transformer substation inspection robot. The method includes the steps of setting a navigation path and stop position markers in advance, the inspection robot automatically identifying the inspection path and the stop positions through machine visual sense, laying a navigation marker line on a transformer substation road, setting identification points with different shapes on the navigation marker line to mark the current inspection position of the robot and key inspection equipment, and conducting real-time video capture and real-time control on the robot. The vision-based navigation and positioning control method has the advantages of high anti-interference performance, capability of running on a complex road, high stability and high accuracy.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

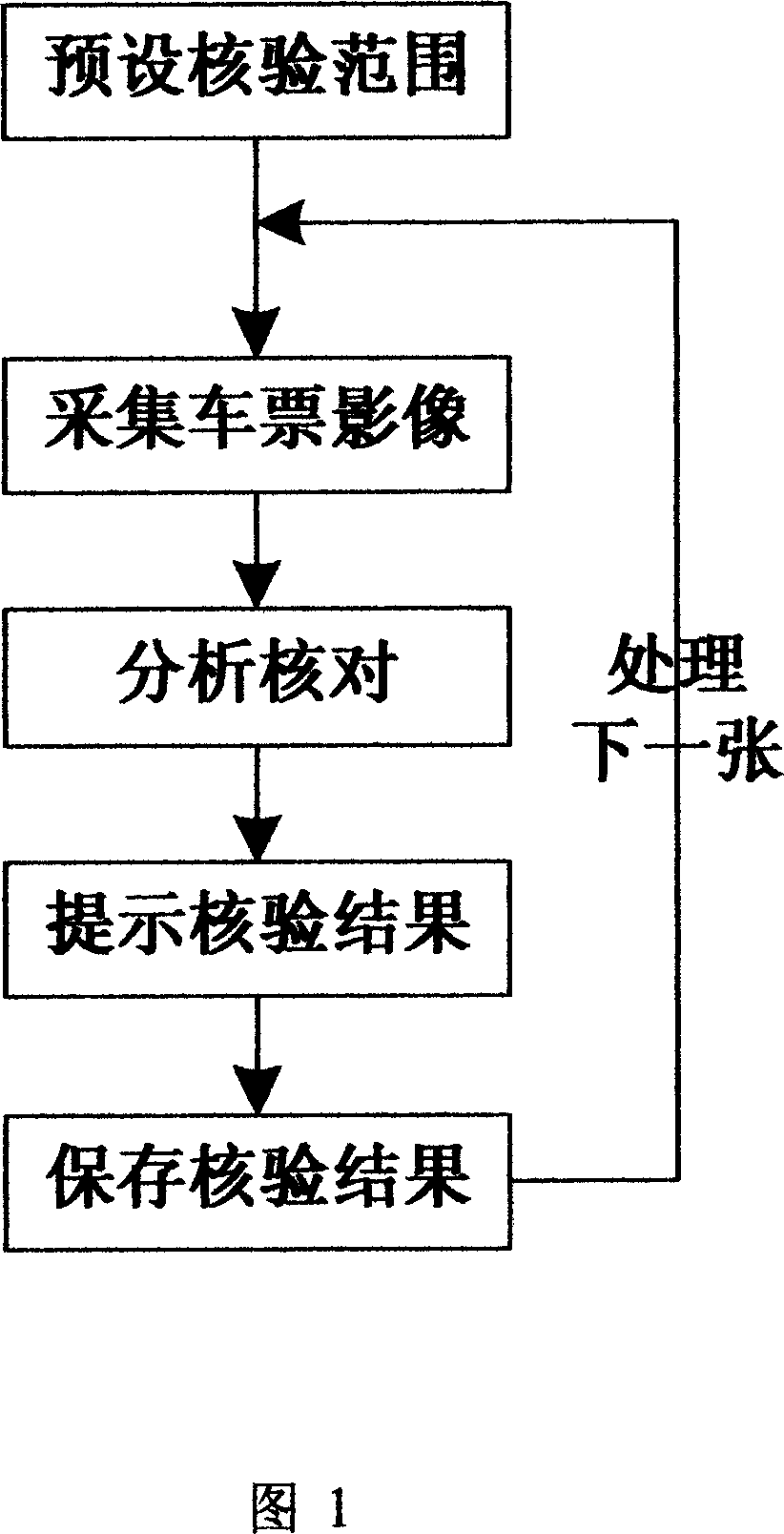

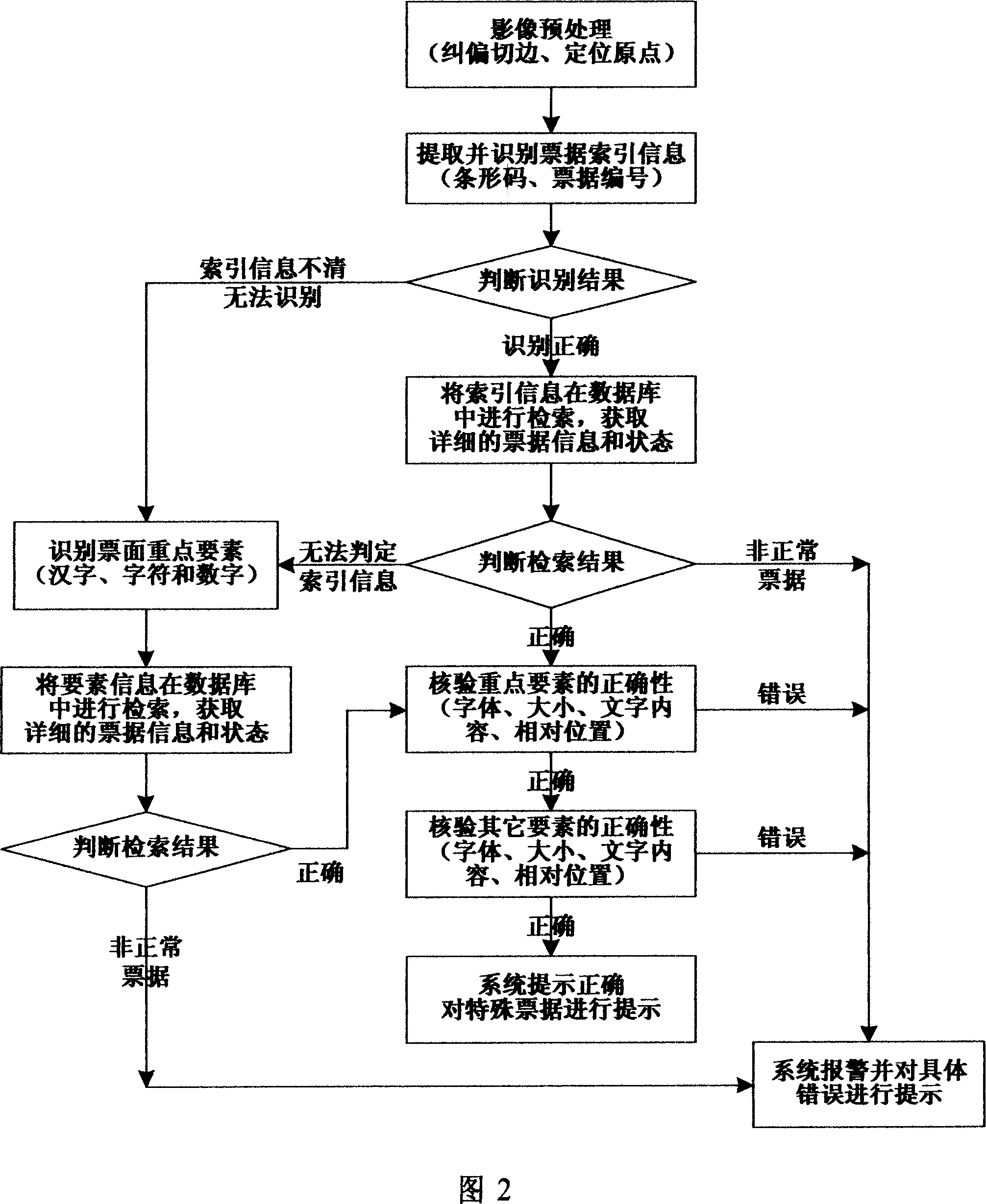

A ticket true/false verifying system and method

InactiveCN101059885AHigh degree of automationFast inspectionPaper-money testing devicesCharacter and pattern recognitionAutomationSelf-service

The invention relates to a ticket check system and a method, which realizes full-automatic check on the ticket, with complete check content, high automation and high check speed. Therefore, the invention can be widely used in ticket check at entrance, movable terminal and self-service or the like.

Owner:朱杰

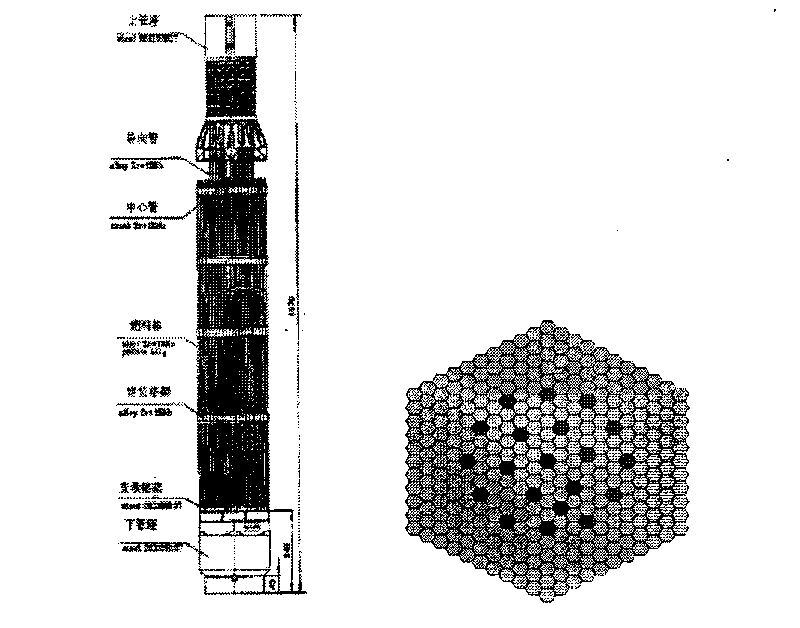

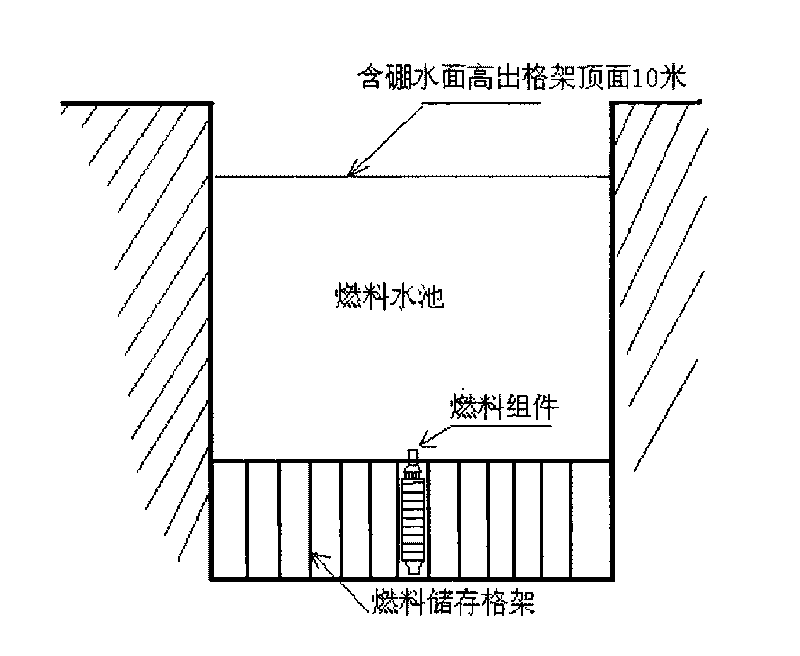

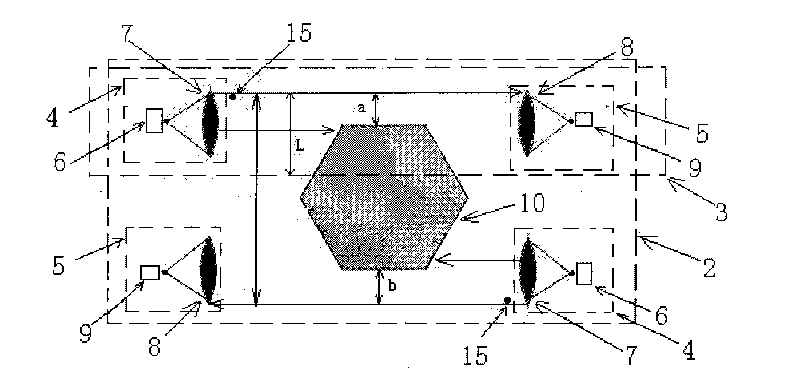

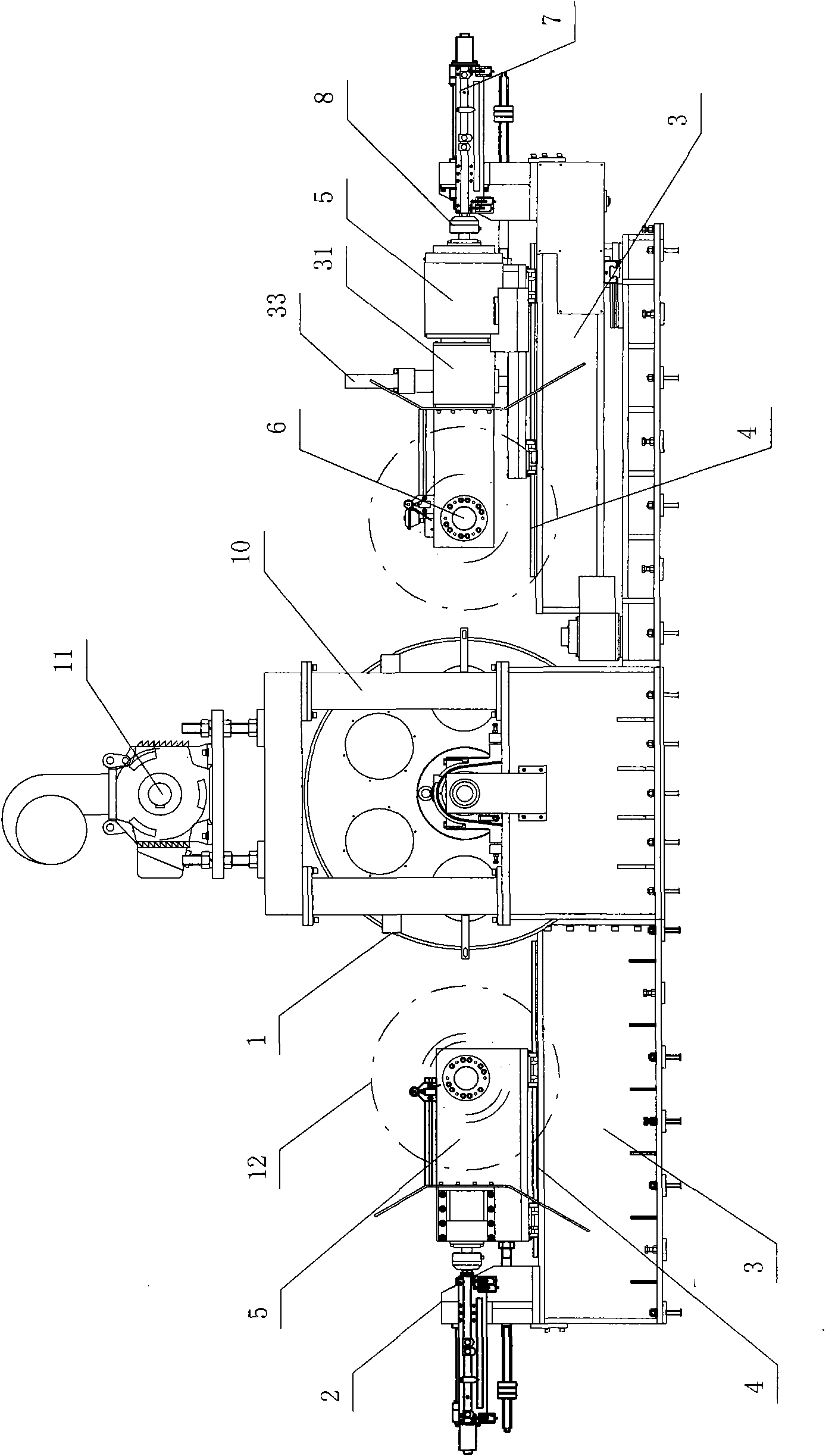

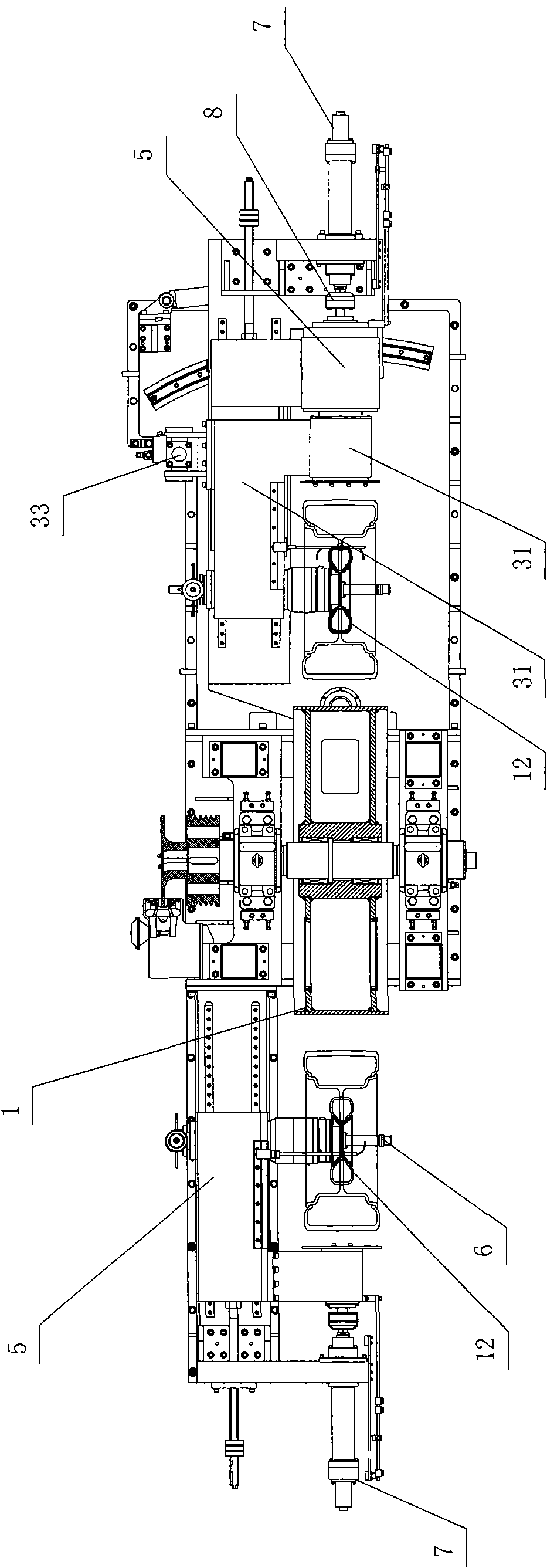

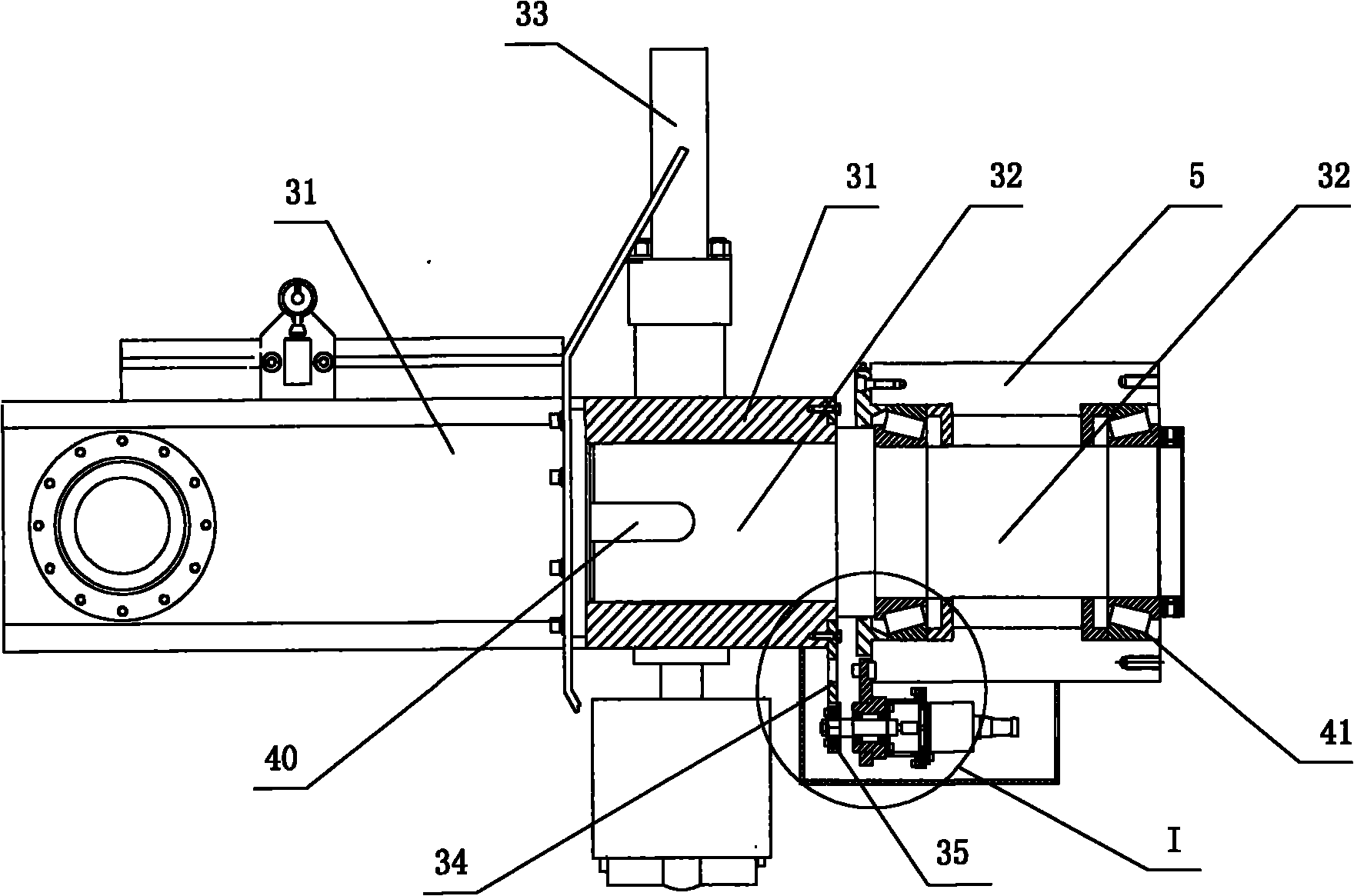

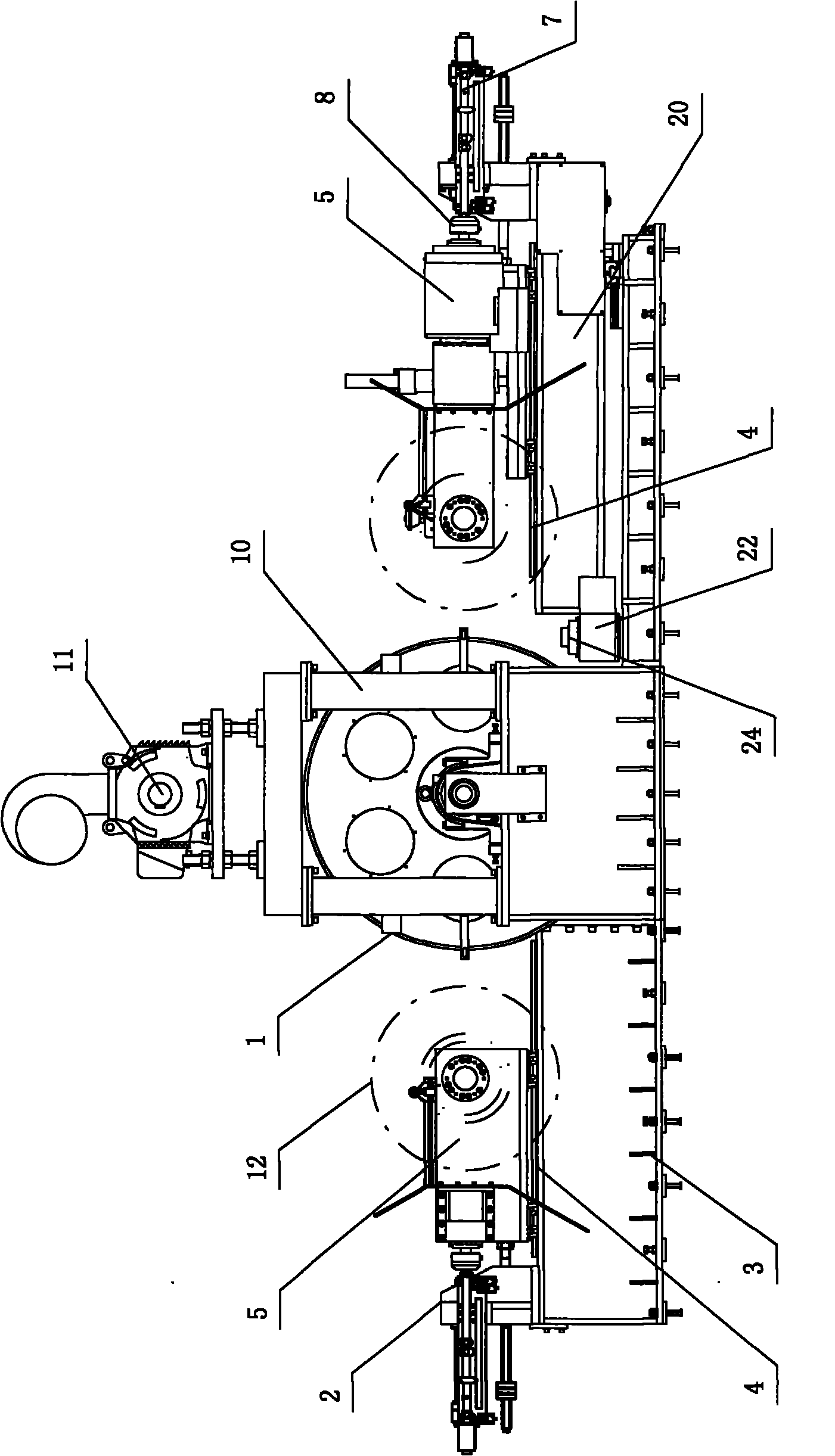

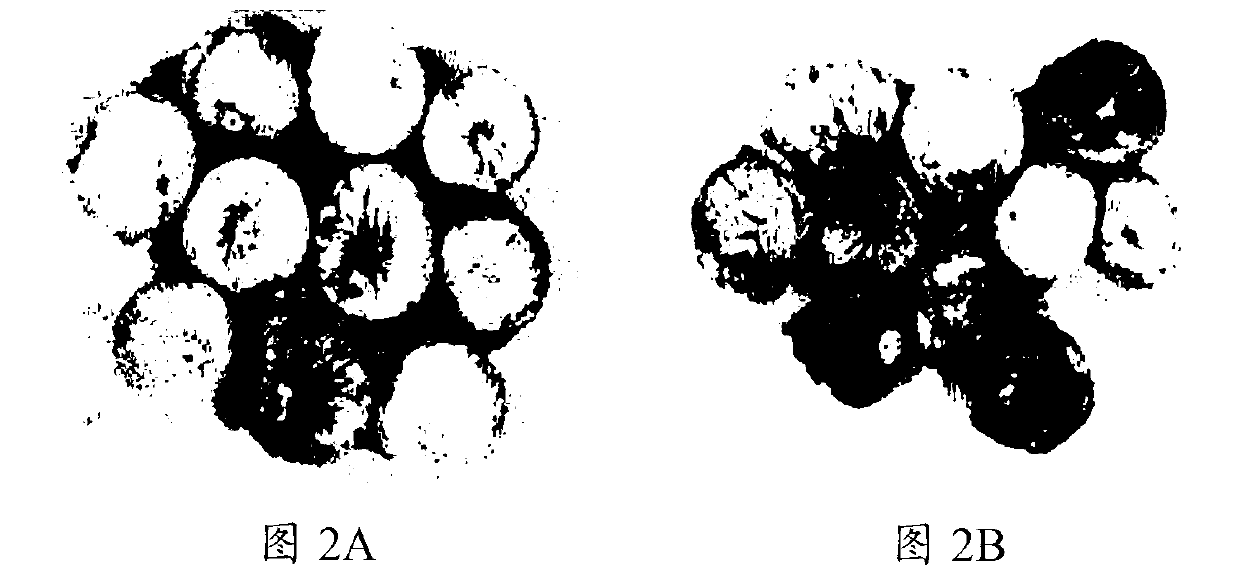

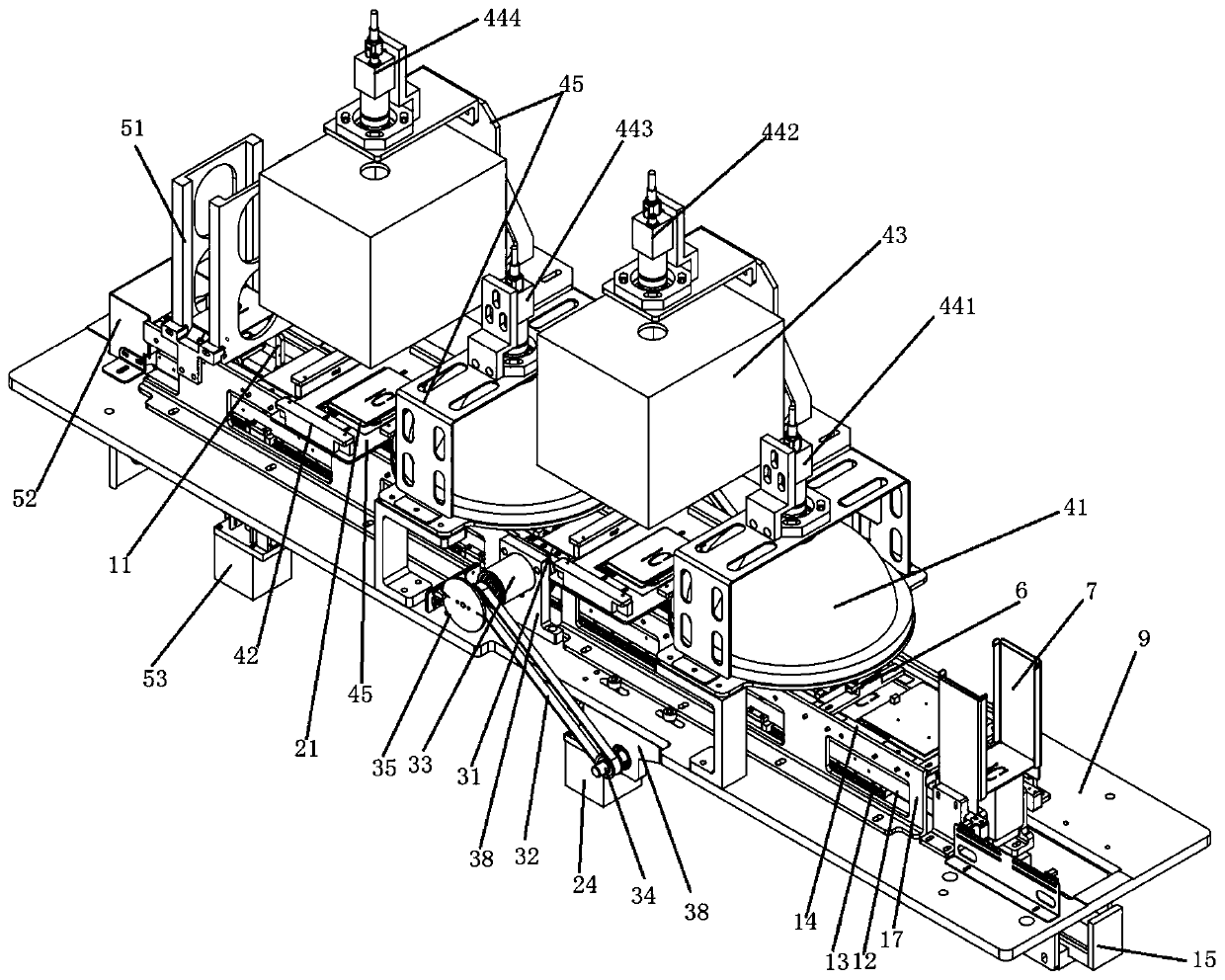

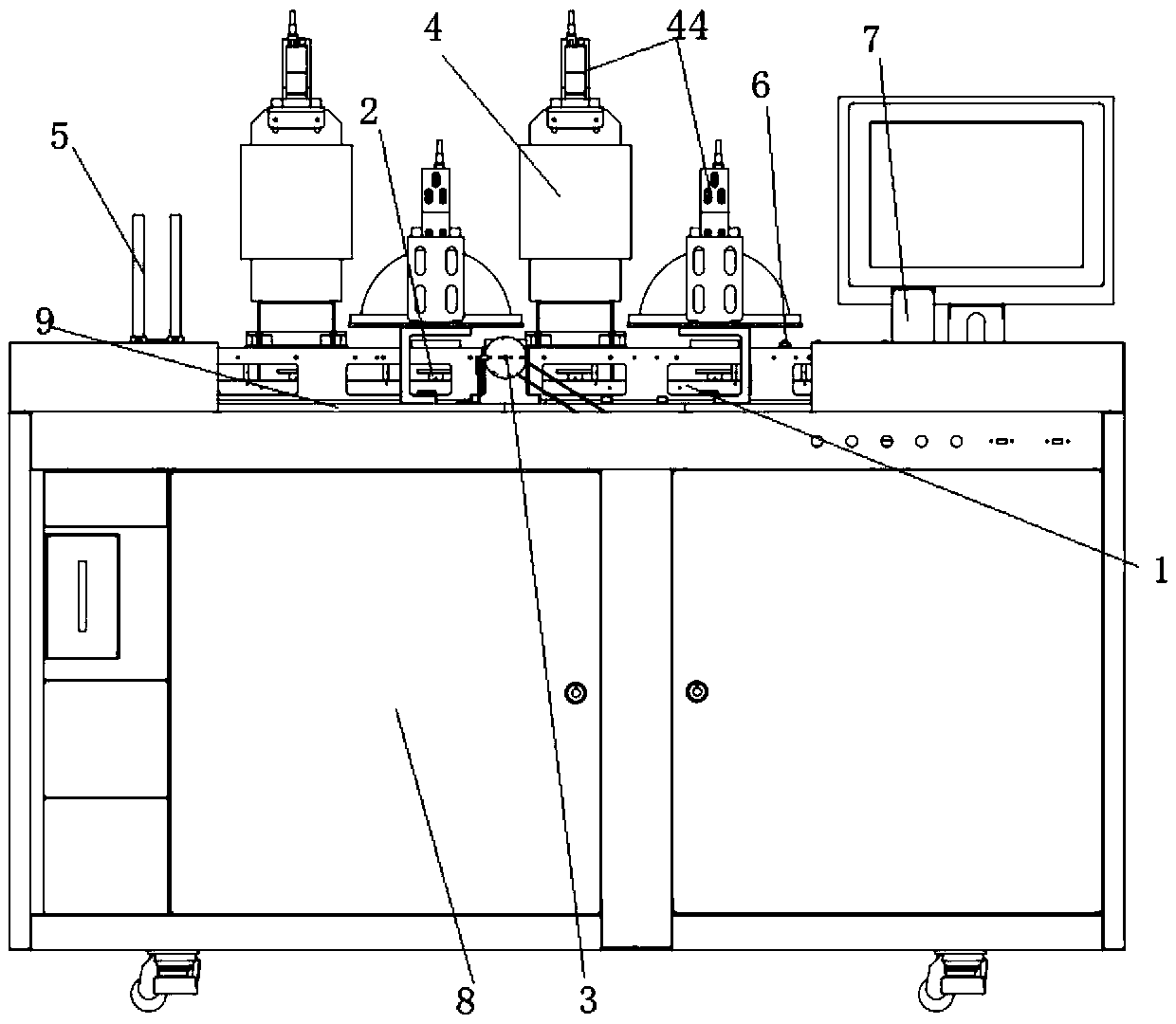

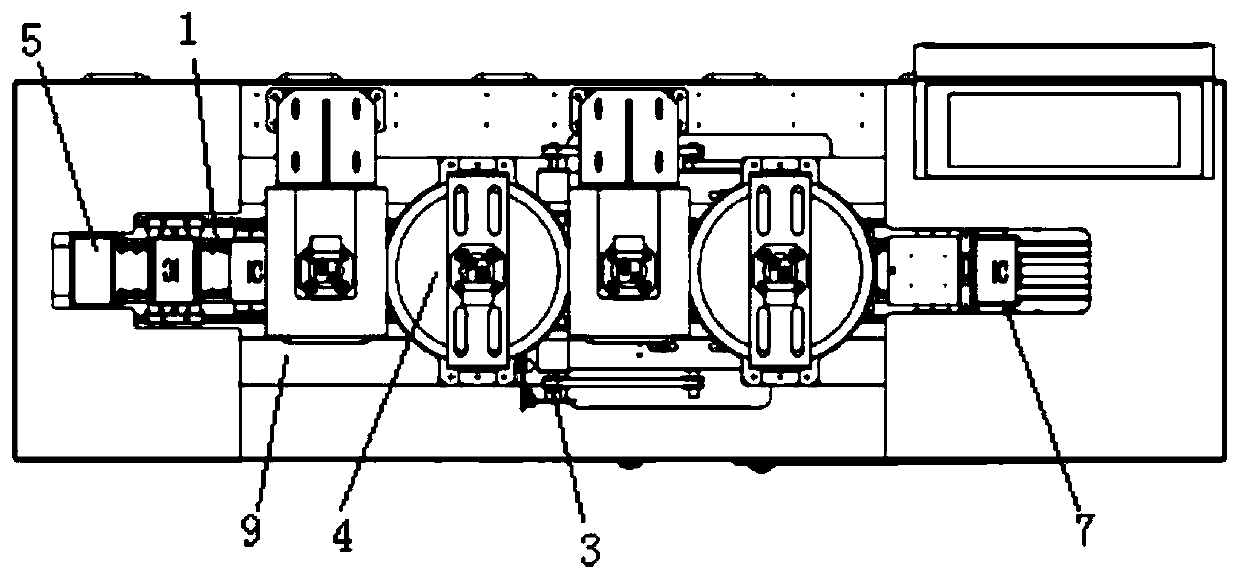

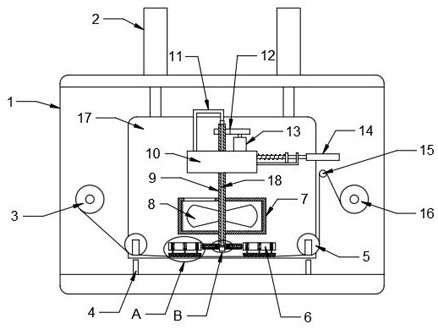

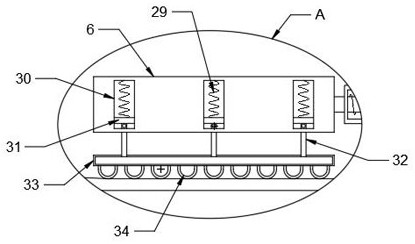

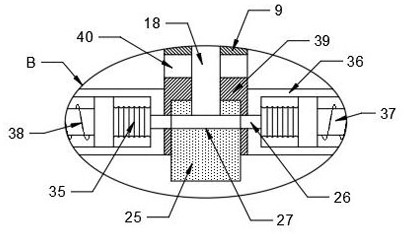

Method for detecting deformation of fuel assembly after irradiation of pressurized-water reactor nuclear power plant and implementation device thereof

ActiveCN101727996ACheck the detailsComprehensive inspectionNuclear energy generationNuclear monitoringPressurized water reactorNuclear engineering

The invention belongs to the technical field of detection, and in particular relates to a device and a method for detecting deformation size of a fuel assembly after irradiation of a pressurized-water reactor nuclear power plant, which solve the problem of low precision and poor insurance in the prior art. The detecting device mainly comprises an annular base (1) and detection sets (2), wherein a plurality of detection sets (2) are evenly distributed on the annular base (1); each detection set (2) comprises a pair of detection units (3) placed reversely in parallel; the number of the detection units (3) is the same as the edge number of the fuel assembly (10); and the detecting method adopts the detection set (2) consisting of the two detection units (3) to measure the width of an opposite side of the fuel assembly, the diameter of fuel rods and the clearance between the fuel rods. The method and the device can inspect the curve and torsion of the fuel assembly after the irradiation of the nuclear power plant, the opposite side distance of a grillwork and the clearance between the fuel rods; and edges of the fuel assembly can be inspected at the same time by adopting the arrangement of a plurality of units, and the detection efficiency is high.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

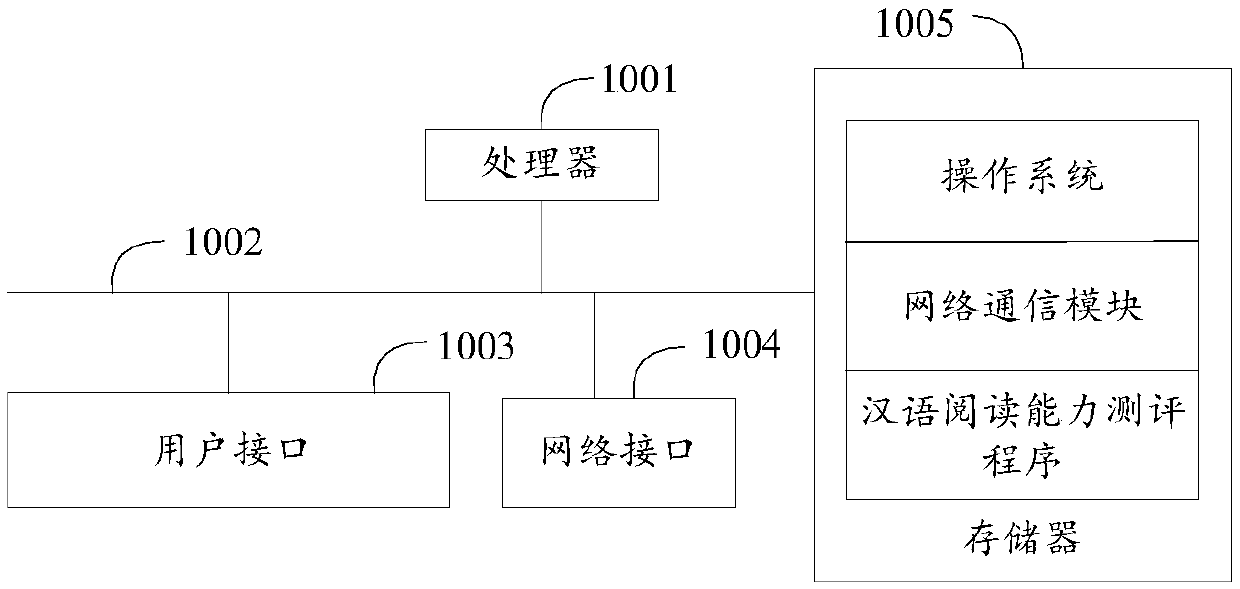

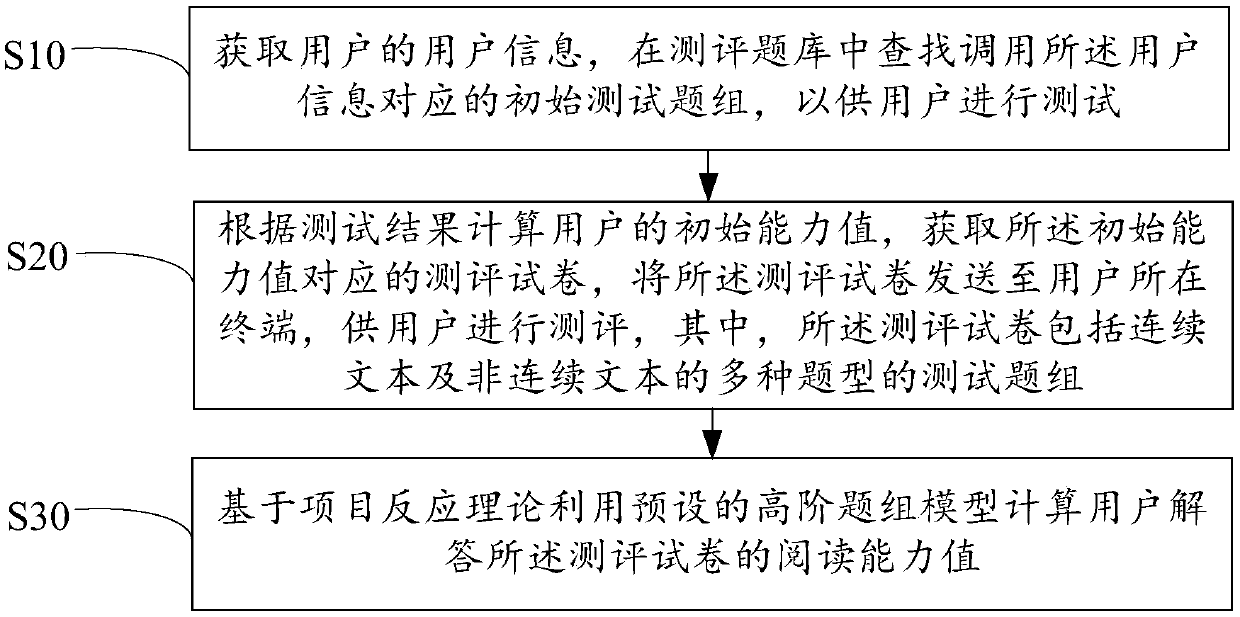

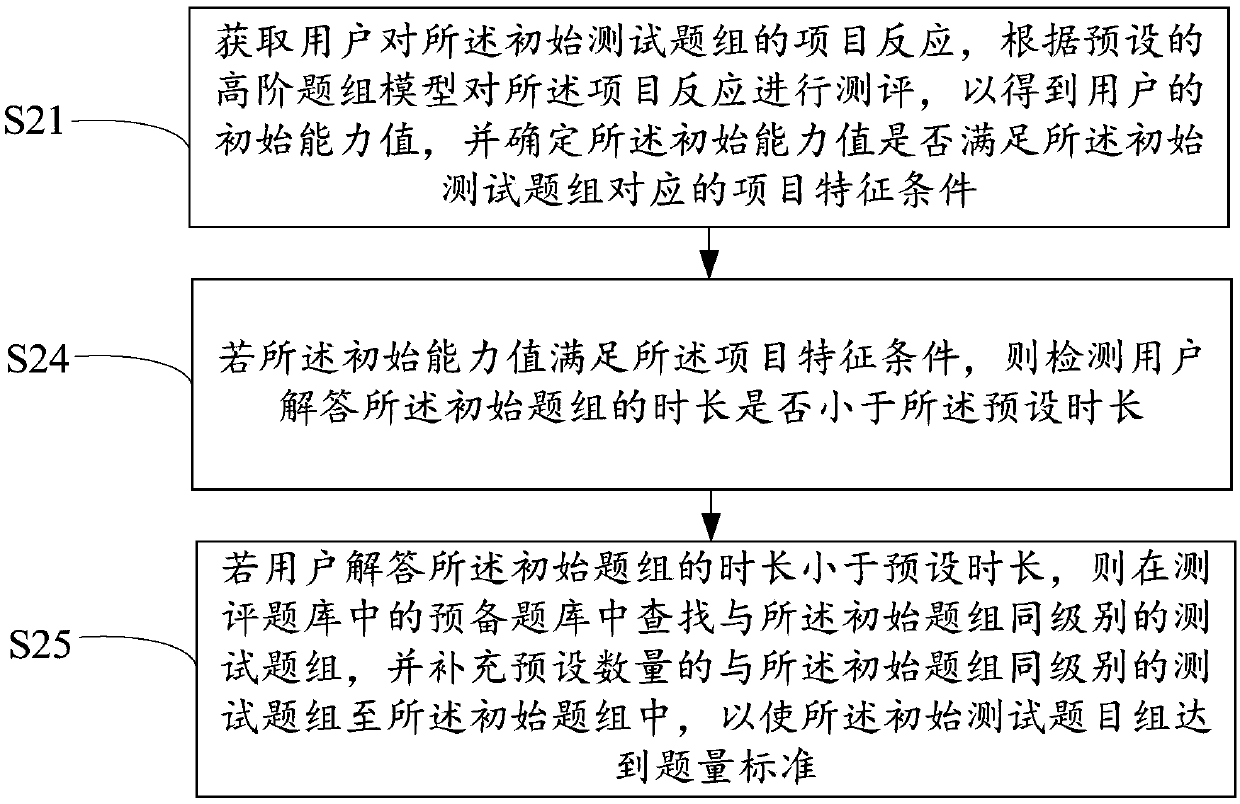

Chinese reading ability evaluation method and device and readable storage medium

ActiveCN109523194AHave diversityInspection is accurateDigital data information retrievalResourcesComputer terminalTest question

The invention provides a Chinese reading ability evaluation method, which comprises the following steps of: obtaining user information of a user, and calling an initial test question group corresponding to the user information in an evaluation question bank for the user to test; Calculating an initial capability value of the user according to a test result, obtaining an evaluation test paper corresponding to the initial capability value, and sending the evaluation test paper to a terminal where the user is located for the user to perform evaluation, the evaluation test paper comprising test question groups of multiple question types of continuous texts and discontinuous texts; And based on the project response theory, calculating a reading capability value of the user for answering the evaluation test paper by utilizing a preset high-order question group model. The invention also provides a Chinese reading ability evaluation device and a readable storage medium. According to the methodand the system, the user is tested according to the test papers of various question types of the continuous text and the discontinuous text, the item response of the user for answering the test papers is evaluated through the high-order question group model, and the question types have diversity and can more accurately and comprehensively inspect the Chinese reading capability of the user.

Owner:深圳市快乐尼莫文化科技有限公司

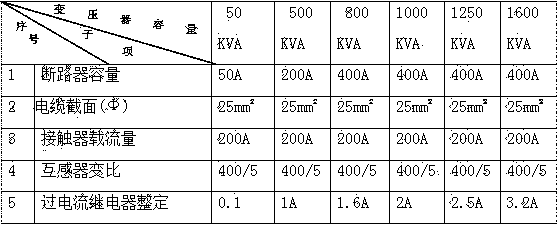

Comprehensive inspecting and testing method for high voltage power transformer and distribution substation

ActiveCN104198832AShorten the construction periodImprove efficiencyElectrical testingTransformerElectrical current

Owner:CHINA METALLURGICAL CONSTR ENG GRP

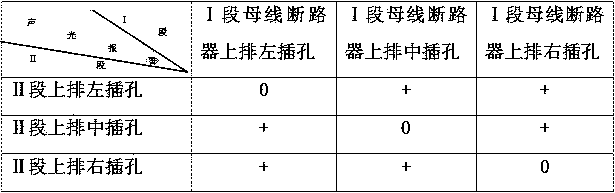

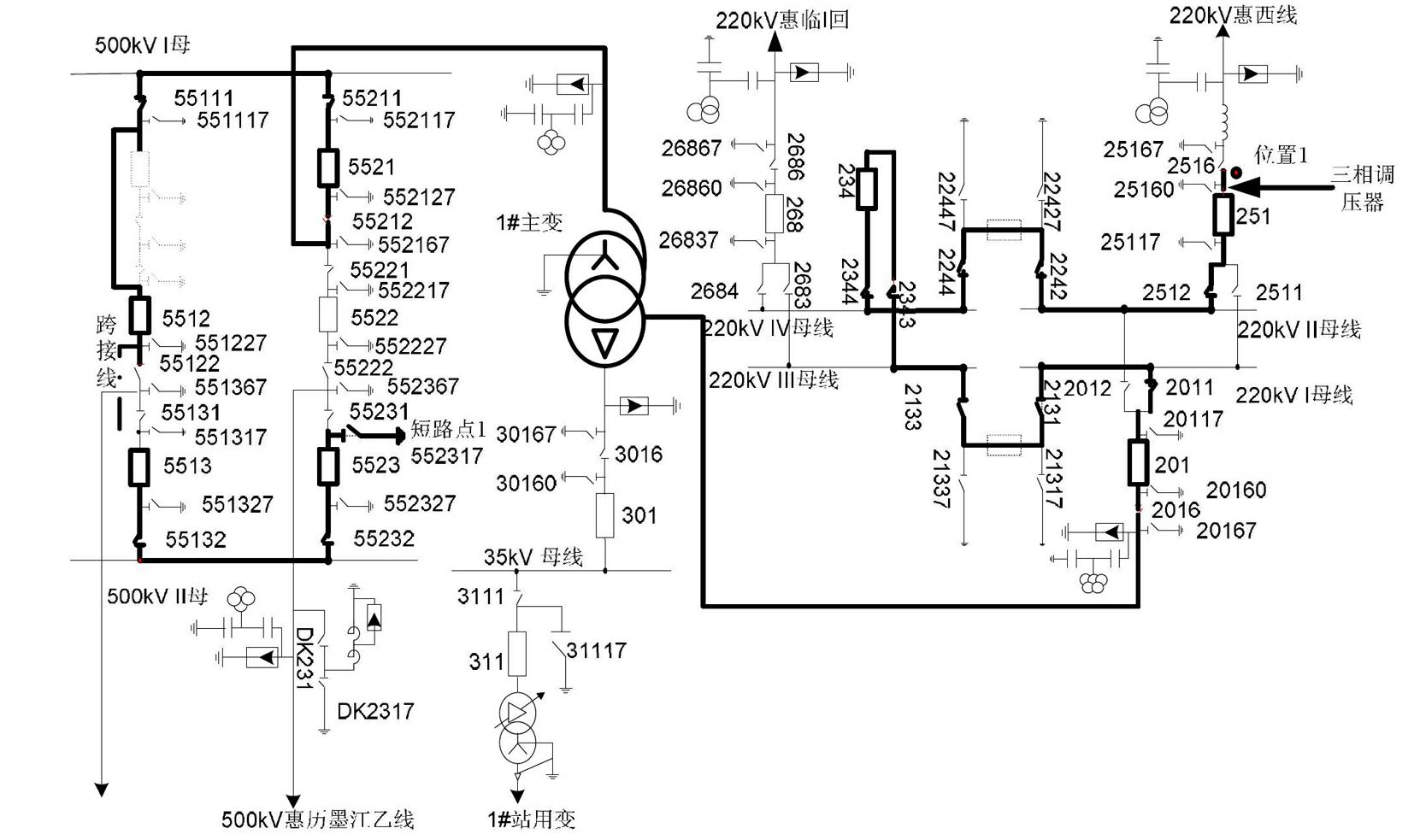

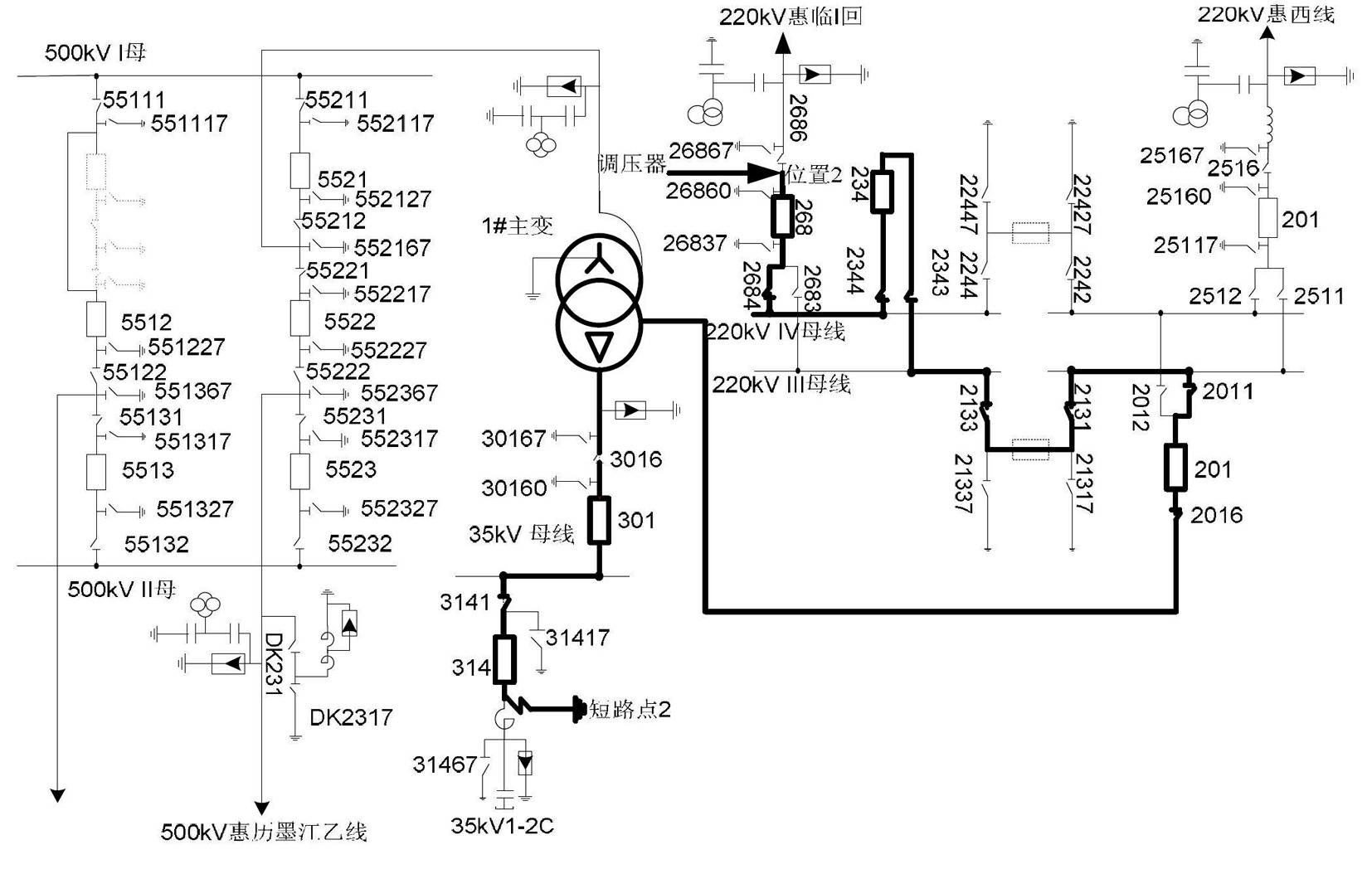

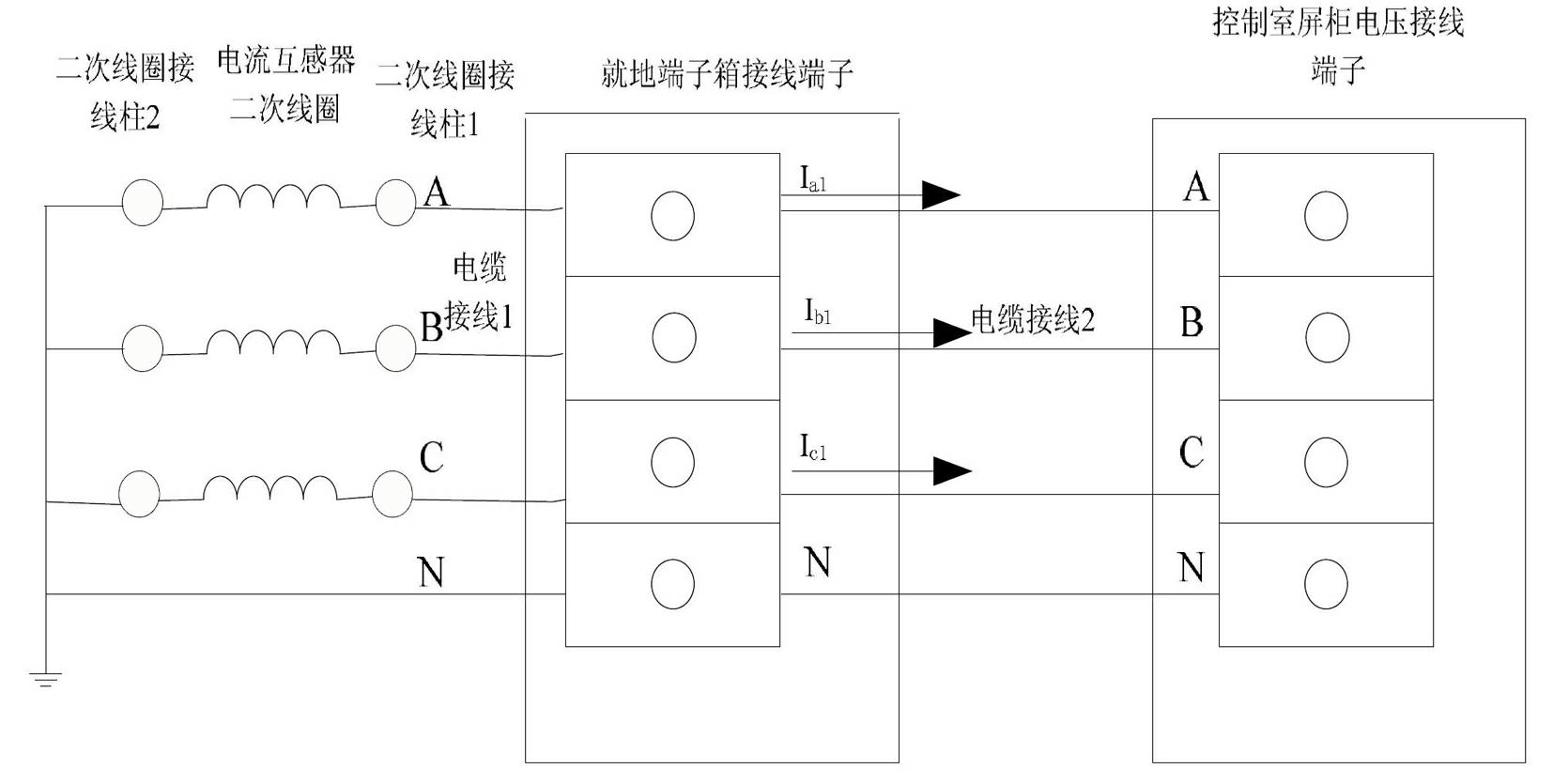

Method of checking alternating current loop of a 500kV transformer substation through carrying out simulated through-type three-phase short circuit

ActiveCN102540001AAccurate discoveryComprehensive inspectionElectrical testingElectrical polaritySecondary loop

The invention provides a method of checking an alternating current loop of a 500kV transformer substation through carrying out simulated through-type three-phase short circuit. According to the method, before the 500kV transformer substation is electrified and put into production, a simulated through-type three-phase short circuit system is carried out so as to check the correctness of the amplitude value, phase, polarity and wiring of the current loop of the whole substation. The method provided by the invention has the following advantages: (1), after problems are discovered, the time for searching and processing the problems is sufficient; (2), the check content for an alternating current secondary loop is more comprehensive and systematic; (3), the polarity wiring condition of a current transformer can be accurately judged; and (4) materials of equipment used in the method are simple and convenient, the workload is less, the current loop of the whole substation can be checked through simple operations, and the workload and test time can be reduced.

Owner:YUNNAN POWER GRID

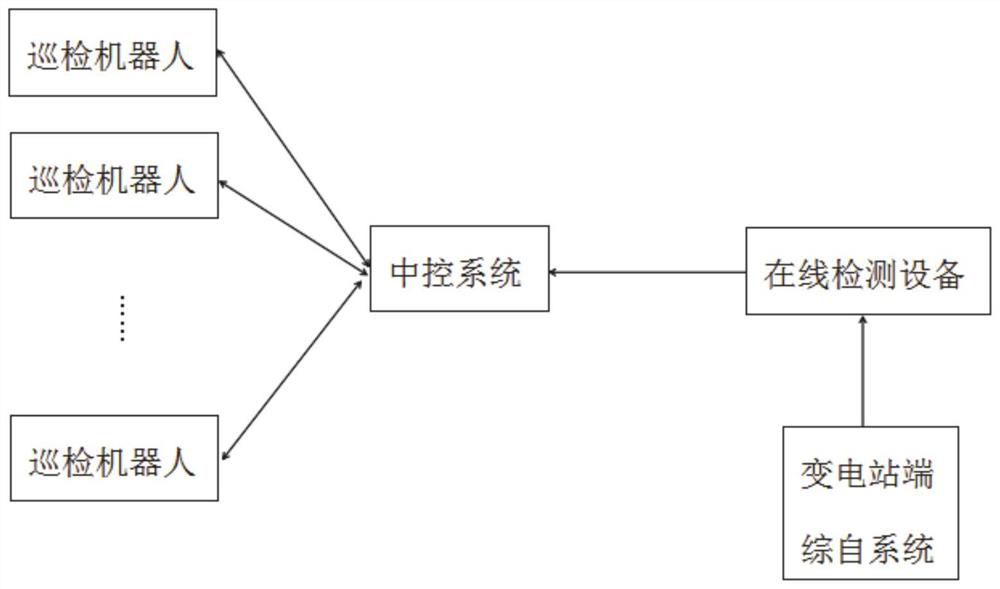

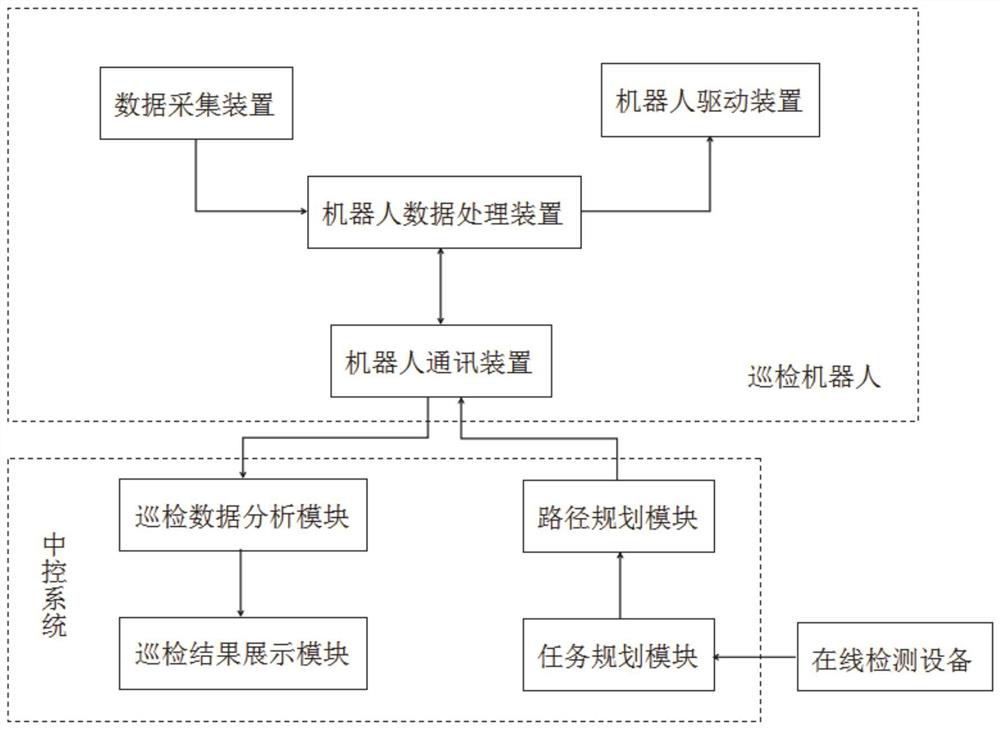

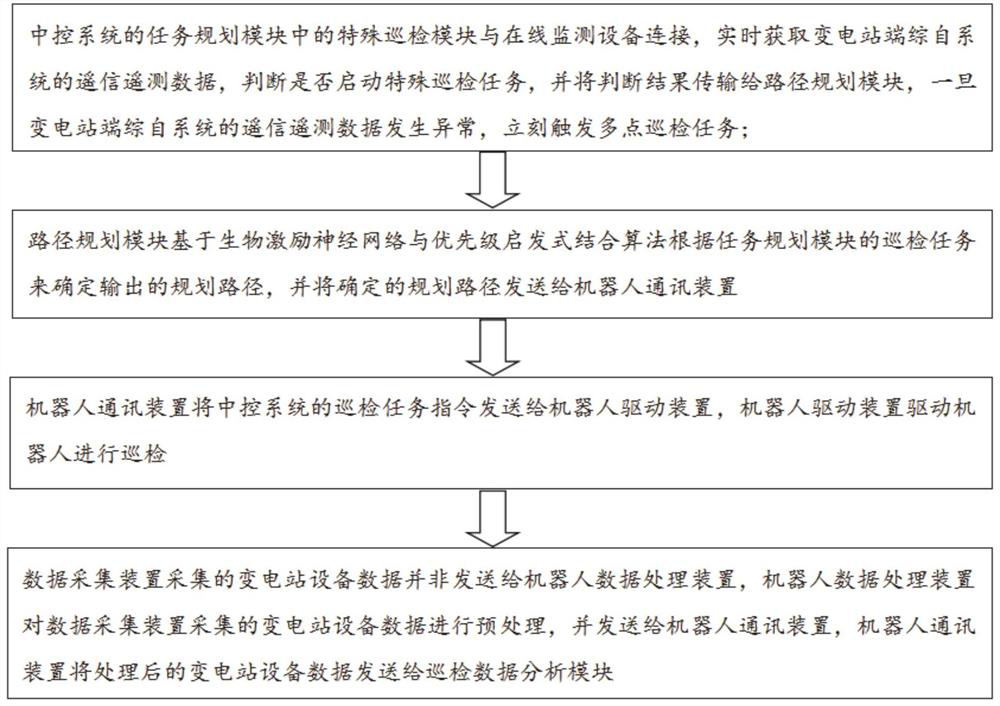

Intelligent inspection system for transformer substation

ActiveCN113381331AComprehensive inspectionEfficient inspectionCircuit arrangementsInformation technology support systemPathPingControl system

The invention provides an intelligent inspection system for a transformer substation. The intelligent inspection system comprises a central control system, a plurality of inspection robots and online monitoring equipment. The online monitoring equipment is connected with a transformer station end integrated automation system, obtains remote signaling and telemetering data of the transformer station end integrated automation system in real time, and feeds back the data to the central control system in real time. The central control system comprises a task planning module and a path planning module; the task planning module comprises a special inspection module and a periodic inspection module, and the special inspection module is connected with the on-line monitoring equipment and is used for acquiring remote signaling and telemetering data of the transformer station end integrated automation system in real time, judging whether to start a special inspection task or not and transmitting a judgment result to the path planning module; and the periodical inspection module is used for setting periodical inspection tasks and transmitting the periodical inspection tasks to the path planning module. Whether special inspection of the robot is started or not is judged by acquiring the remote signaling and telemetering data of the transformer station end integrated automation system, targeted inspection is facilitated, and the inspection efficiency of the inspection robot is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO JINING CITY RENCHENG DISTRICT POWER SUPPLY CO +2

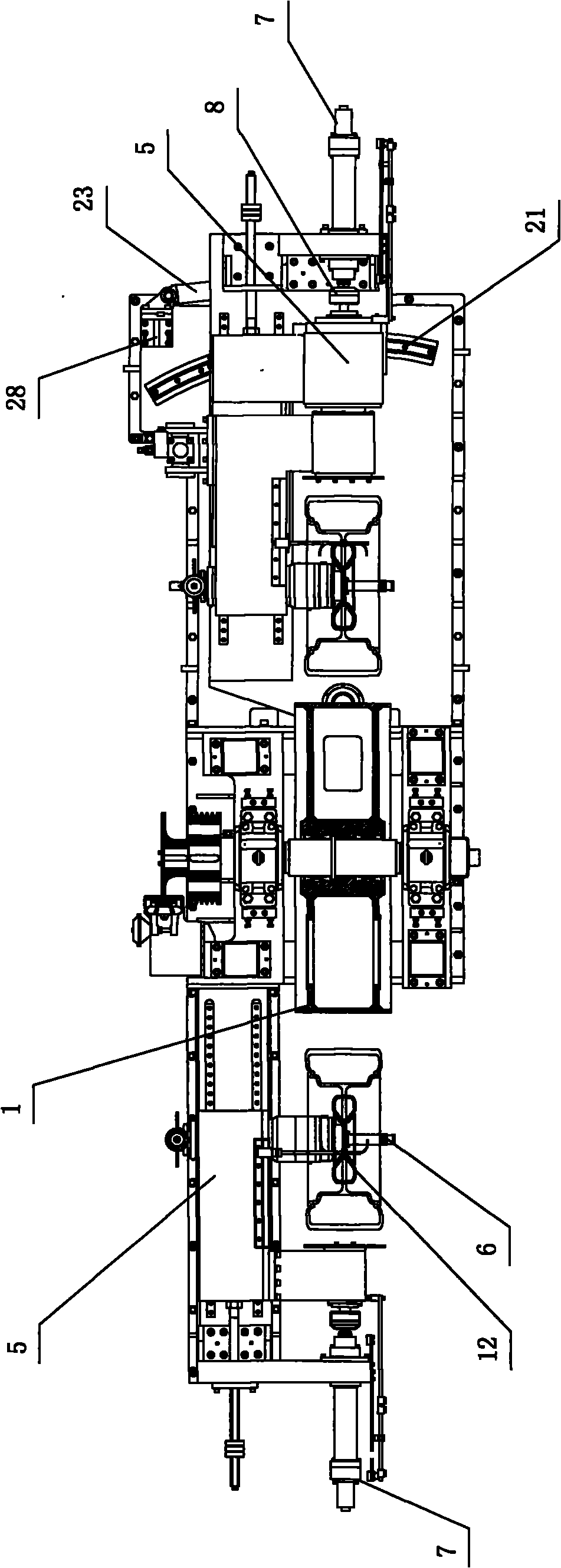

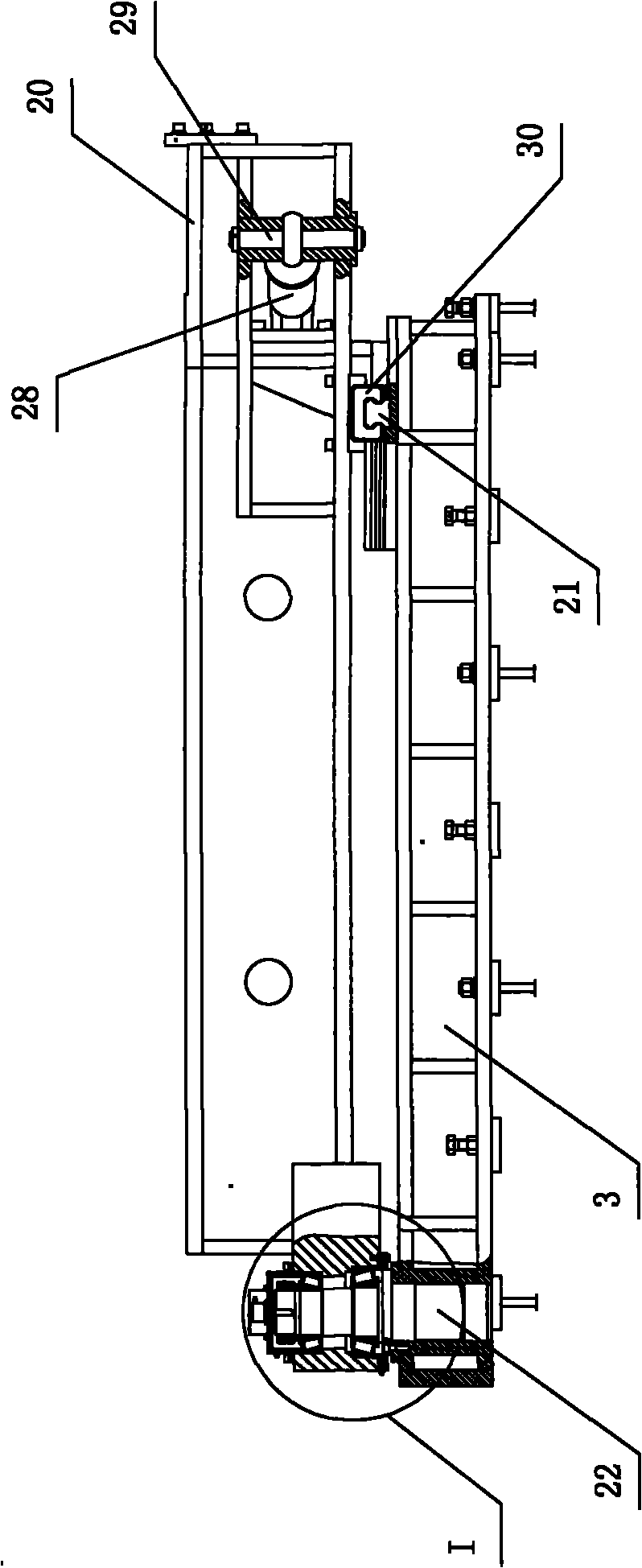

Sliding angle detection device and detection method for tire durablity

ActiveCN102401743AComprehensive inspectionSolve high-speed/durability performance testingVehicle tyre testingInvestigating abrasion/wear resistanceHydraulic cylinderRoad surface

The invention relates to a sliding angle detection device and a detection method for tire durability, increases the sliding angle detection device, aims at road conditions of turning or nonlinear running and the like of a vehicle, and simulates detection in a state when a tire and a road surface cause a sliding angle friction. The sliding angle detection device and the detection method comprise a rack, wherein a rotary drum which is driven by a motor for simulating the road surface in running is arranged on the rack, a hydraulic pressure device is arranged at least at a station position at one side of the rotary drum, and a movable seat is supported above a base through a linear sliding rail on the bottom of the movable seat. The rear end of the movable seat is connected with a hydraulic oil cylinder through a force cell, wherein the hydraulic oil cylinder is used for providing push force, so that the tested tire can be pressed on the surface of the rotary drum. A swing bracket is arranged at the front of the movable seat, a rim fixing shaft used for mounting the tested tire is arranged at the front end of the swing bracket; one end of a swing shaft is fixedly sleeved on the swing bracket, and the other end of the swing shaft is rotationally sleeved on the movable seat in the axial direction; and a sliding angle driving hydraulic cylinder is arranged at one side of the swing bracket and is used for driving the tested tire to rotate with a certain angle along a radial tangent through the swing bracket.

Owner:MESNAC

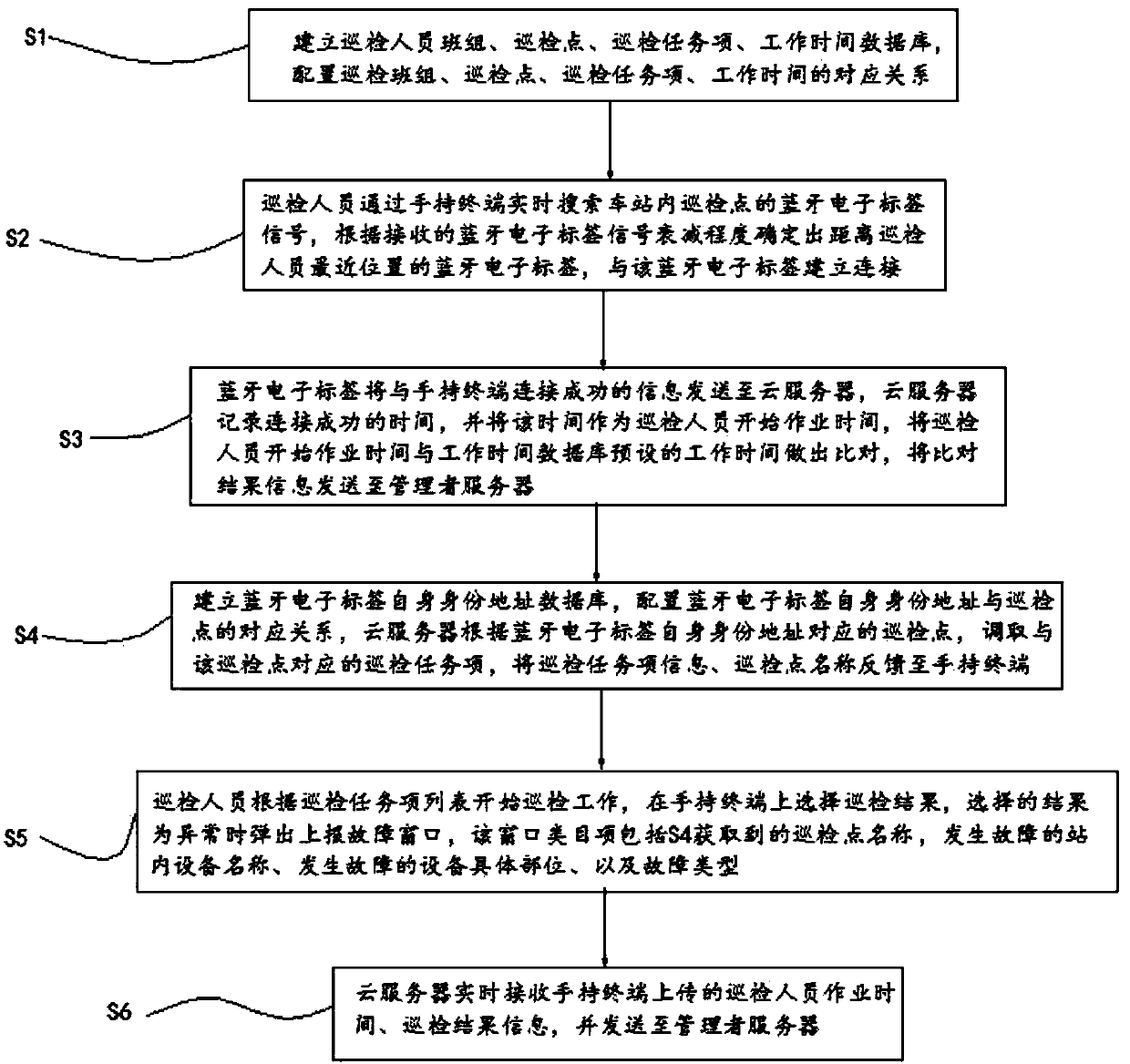

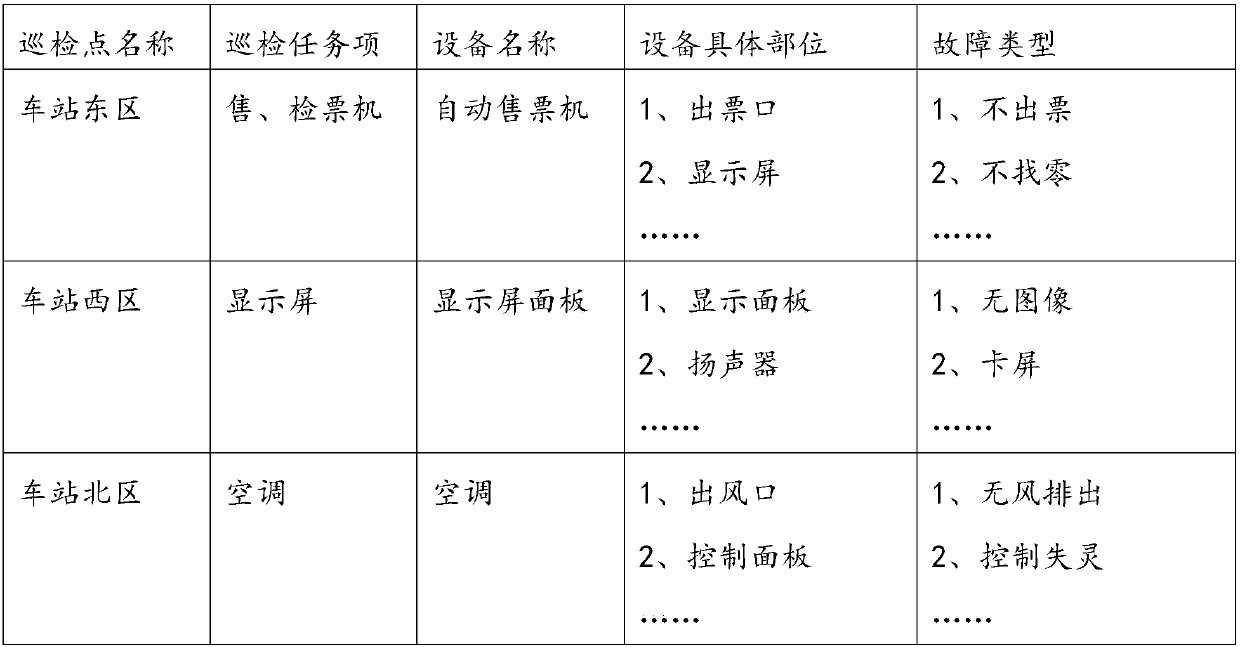

Method for inspecting station by inspection worker

InactiveCN107665518AGet job status in real timeReduce workloadChecking time patrolsResourcesHandwritingStart time

The invention provides a method for inspecting a station by an inspection worker. The method comprises the following steps: S1, configuring a corresponding relation of an inspection team or group, aninspection point, an inspection task item and working time; S2, establishing connection between a handheld terminal and a Bluetooth electronic label; S3, comparing working starting time of the inspection worker with pre-set working time in a working tome database; S4, feeding information of the inspection task item and the name of the inspection point back to the handheld terminal; S5, selecting an inspection result on the handheld terminal; S6, receiving the working time of the inspection worker and inspection result information, which are uploaded by the handheld terminal, by a cloud serverin time and sending the working time and the inspection result information to an administration server. The method provided by the invention has the advantages that manual handwriting type inspectionis replaced by adopting an informational inspection method, so that inspection work is real and effective; compared with other informational inspection methods, a working state of the inspection worker can be obtained in real time; in a present high-speed development process of a computer technology, the high-intelligence inspection method is a necessary trend of the development of the technical field of station inspection.

Owner:北京万相融通科技股份有限公司

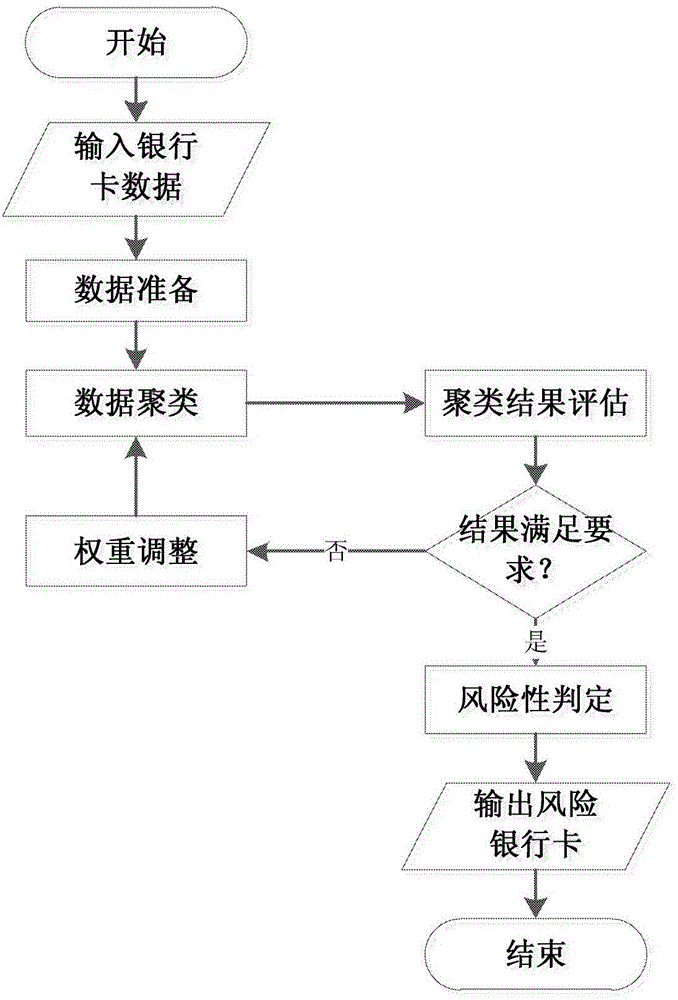

Method for detecting high-risk bankcard and data processing device

ActiveCN105590156AComprehensive inspectionThe result is accurateFinanceResourcesMachine learningRisk model

The invention discloses a method for detecting a high risk of a bankcard. The method comprises steps of: clustering the historical data of each bankcard transaction by using a k-means clustering algorithm in order to obtain a risk model, wherein the historical data, used as training data of the risk model, is classified into a high-end card type and non-high-end card type, and each type of information data is represented by n dimensions; processing the transaction data of a bankcard to be detected into data with a dimensionality the same as that of the training data of the risk model; determining, according to the risk model, whether the processed data complies with a rule and characteristic changing from the non-high-end card type to the high-end card type; and if not, determining that the bankcard is provided with the high risk. The invention also discloses a data processing device.

Owner:CHINA UNIONPAY

Inclination detection device and method for tire durability

InactiveCN102401744AComprehensive inspectionSolve high-speed/durability performance testingVehicle tyre testingHydraulic cylinderEngineering

The invention relates to an inclination detection device and a method for tire durability, and provides an additional inclination detection device and a technical method of specifically improving a tire wear tracking and detecting means. The detection method for high speed / durability of a tire inclined in running is added mainly based on simulation of mounting inclination of the tire, and road conditions such as surface inclination, unevenness and the like. The detection device mainly comprises a frame, a drum driven by an electric motor to rotate around a fixed axis and simulate a pavement for running is disposed on the frame, a hydraulic pressing device and a movable seat are disposed on two lateral stations of the drum, an arc horizontal guide rail and a perpendicularly fixed swing shaft are disposed on a base, a swing seat is mounted between the base and the movable seat, the bottom of the swing seat is slidably connected to the horizontal guide rail, one end corner of the swing seat is sleeved to the swing shaft, an inclination drive hydraulic cylinder which drives the swing seat to incline on the horizontal guide rail and by centering on the swing shaft is disposed between the base and the swing seat.

Owner:MESNAC

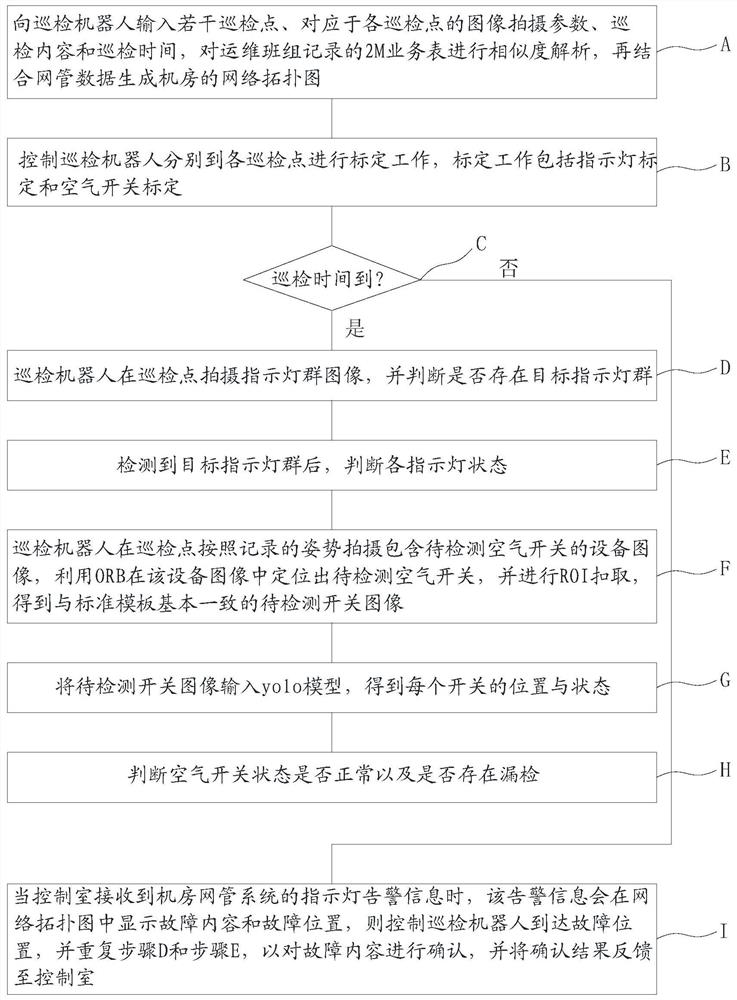

Machine room inspection method and device

ActiveCN112766103APrevent overfittingImprove generalization abilityChecking time patrolsCharacter and pattern recognitionInformation controlImage detection

The invention provides a machine room inspection method, which comprises the following steps of: A, inputting a plurality of inspection points, image shooting parameters, inspection contents and the inspection time into an inspection robot, and generating a network topological graph; b, carrying out calibration work; c, performing routing inspection when the routing inspection time is up, otherwise, entering the step I; d, shooting an indicator lamp group image at the inspection point; e, detecting the state of an indicator lamp; f, shooting an equipment image containing the to-be-detected air switch, and positioning the to-be-detected air switch; g, inputting the to-be-detected switch image into the yolo model to obtain the position and the state of each switch; h, judging whether the air switch state is abnormal or not and whether leak detection exists or not; and I, receiving alarm information of the network management system, controlling the inspection robot to arrive at the fault position, and repeating the step D and the step E. The invention further provides a machine room inspection device. According to the invention, an accurate network topological graph can be generated, the detection with strong anti-interference performance, low false detection rate and high accuracy is achieved, and the inspection of the machine room is more comprehensive.

Owner:QUANZHOU POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +2

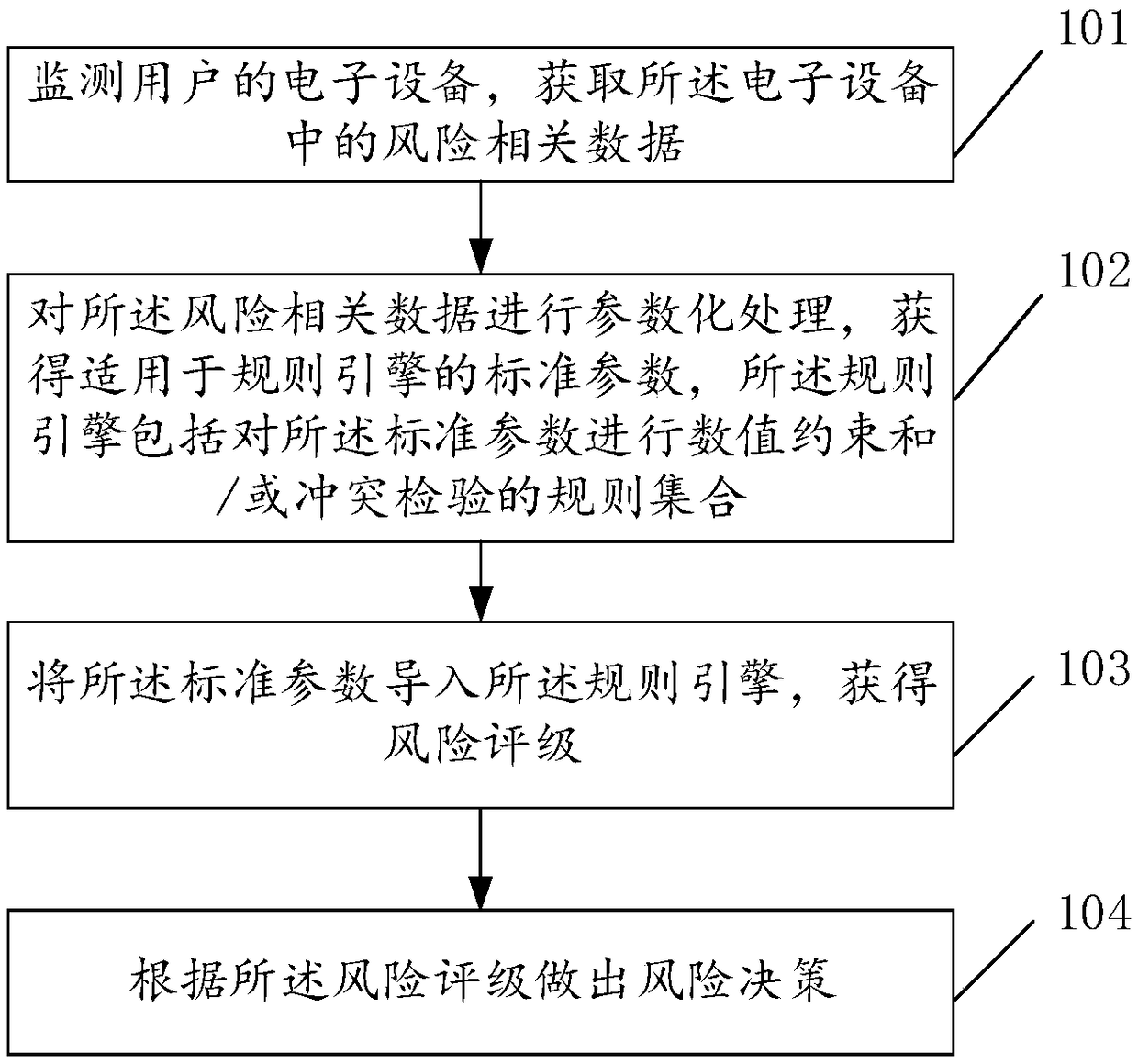

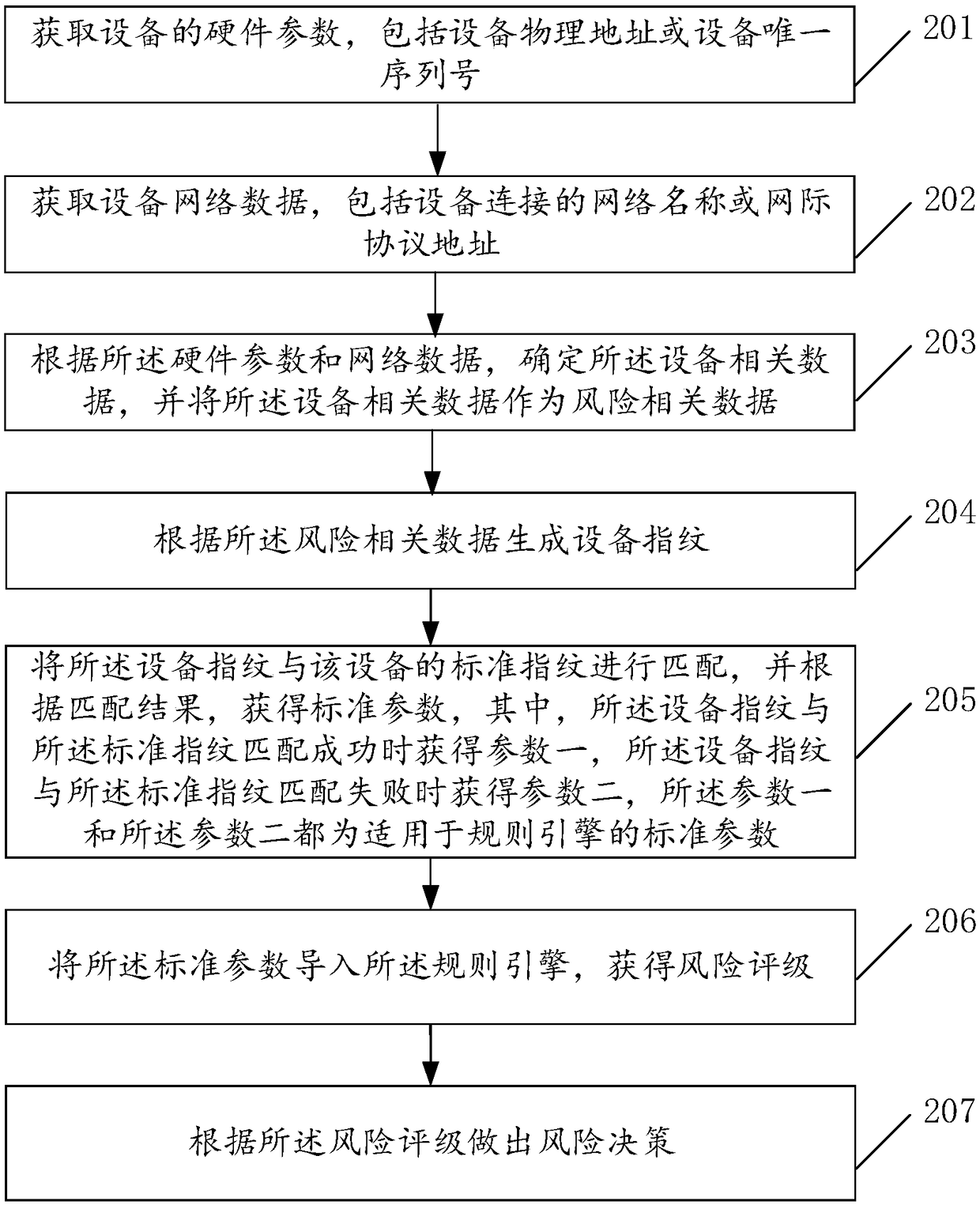

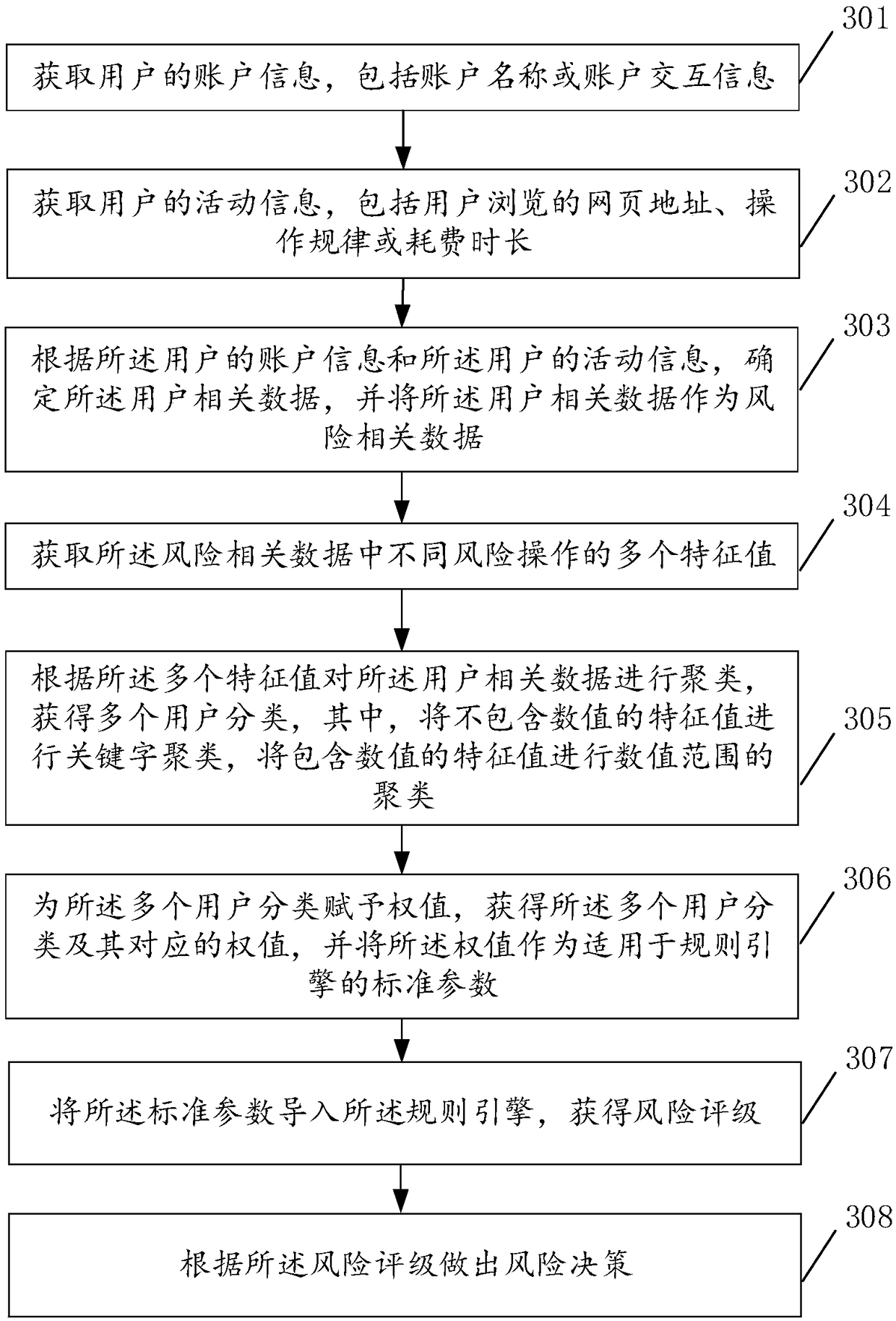

A method and apparatus for risk decision

The embodiment of the invention discloses a risk decision method and a risk decision device, wherein, the risk decision method comprises the following steps: monitoring an electronic device of a userand obtaining risk-related data in the electronic device; parameterizing the risk-related data to obtain the standard parameters suitable for the rule engine; importing the standard parameters into the rule engine to obtain the risk rating; making risk decisions based on risk ratings. By adopting the invention, the generation of risk decision can be influenced through standardization of risk related data, rule engine processing and risk rating, and the adopted parameters and rule engine improve the comprehensiveness and normalization of risk rating, and the accuracy and referenceability of risk decision can be improved through risk rating.

Owner:PING AN TECH (SHENZHEN) CO LTD

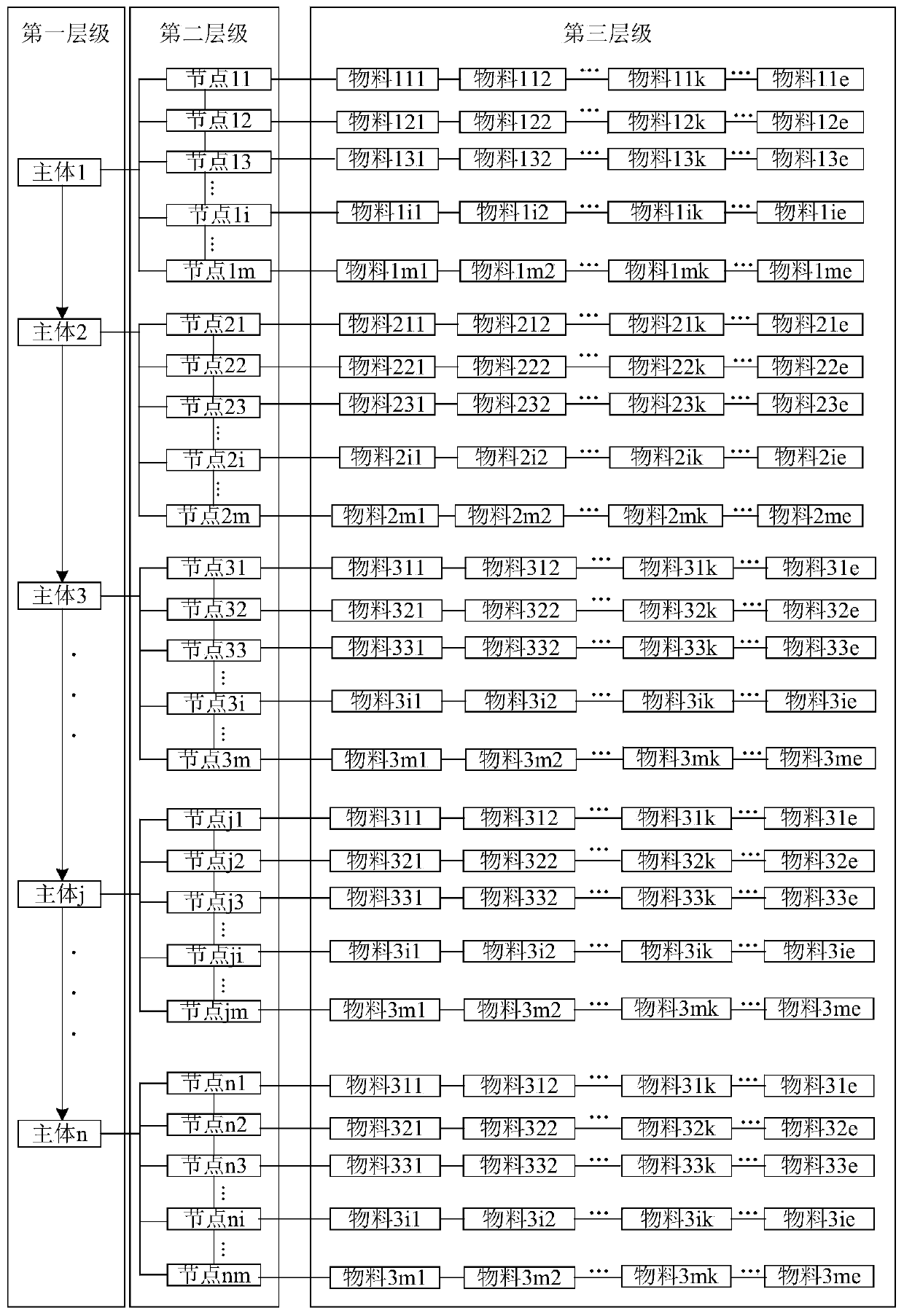

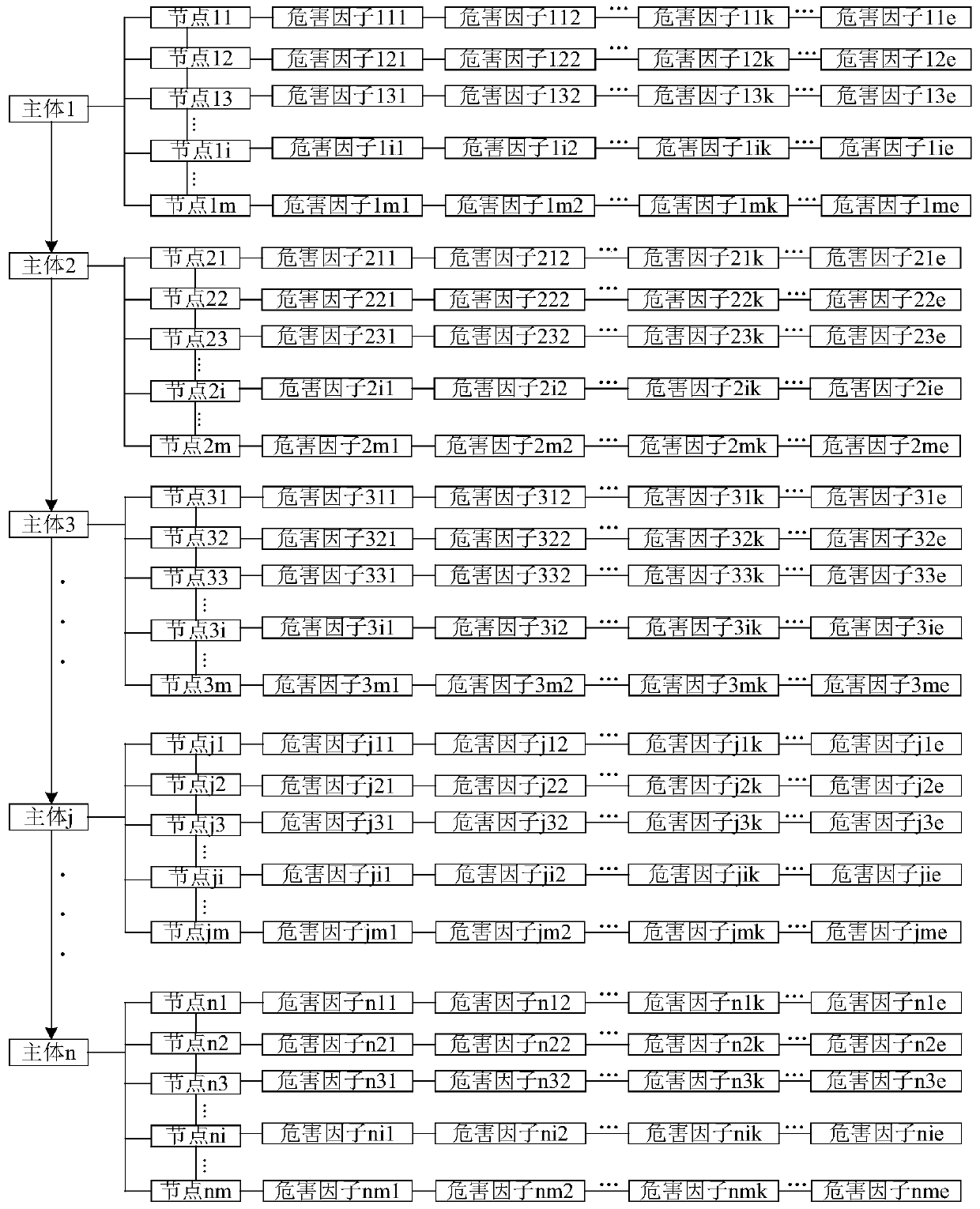

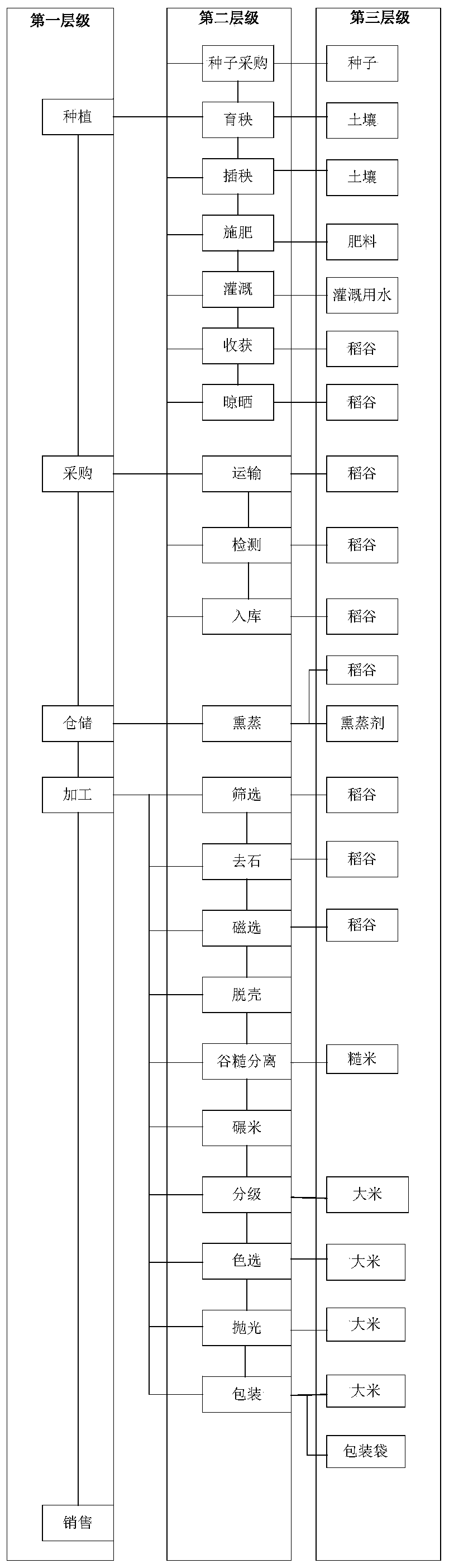

Food safety assessment method of multi-source information

The invention belongs to the technical field of food safety, and particularly relates to a multi-factor food safety risk comprehensive evaluation method. The method comprises the following steps: (1)determining a food full-chain process; (2) carrying out full-chain hierarchical treatment on the food; (3) determining food quality safety key control points; (4) identifying the types of risk factorsand measuring the content; (5) determining a key control point risk factor limit value; (6) calculating a relative risk index and a chain risk index; (7) determining an early warning coefficient; and(8) dividing risk levels. Different processing bodies, different processing nodes and related different materials in the food processing process are inspected, evaluation is more comprehensive. The early warning coefficient is determined, early warning in advance can be achieved, and the risk position and the risk magnitude are responded in time. According to the method, different food processingchains, different enterprises and different regions can be taken as the same benchmark for investigation according to specific requirements, and the method is convenient, rapid and efficient.

Owner:HUAZHONG AGRI UNIV

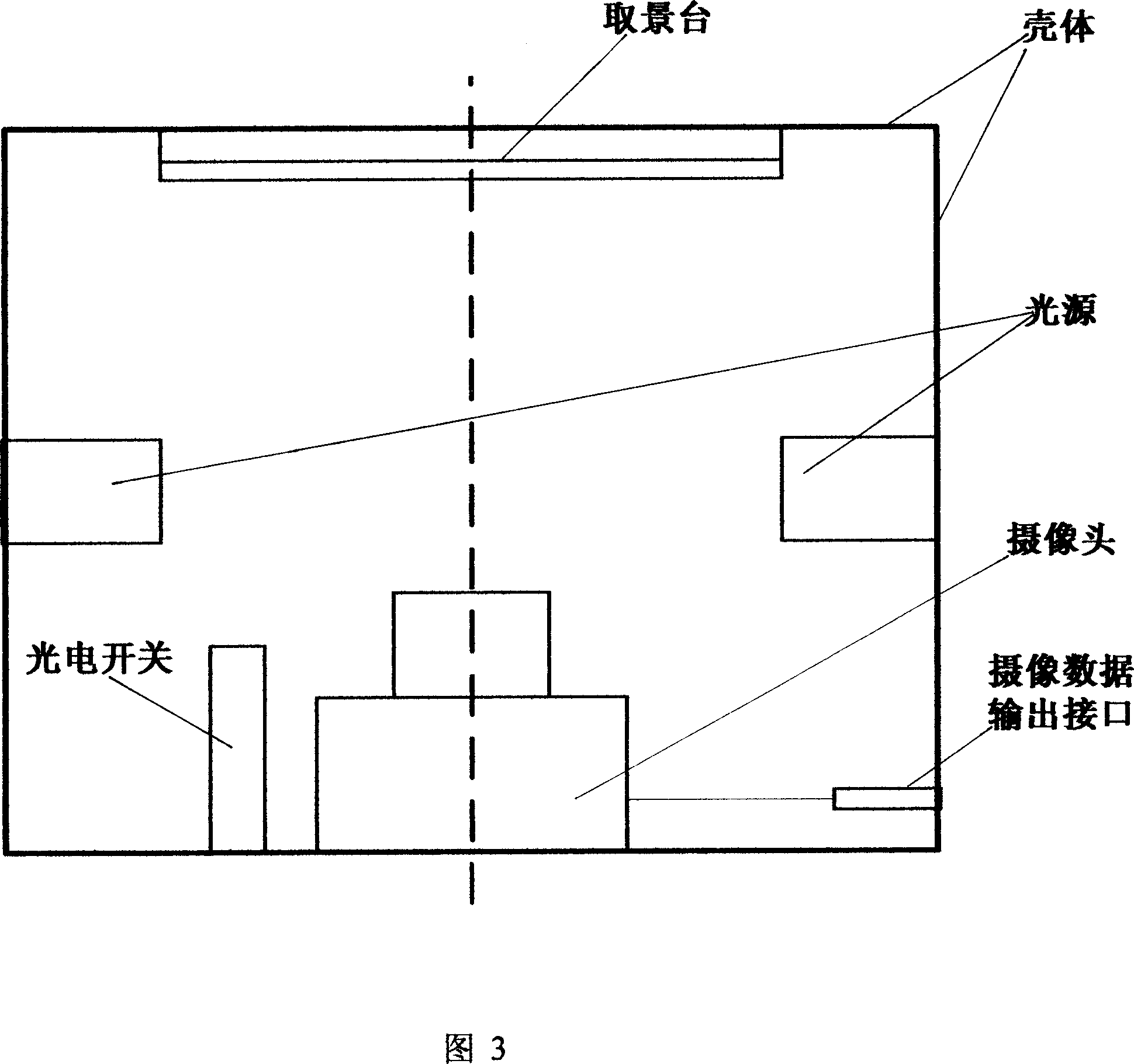

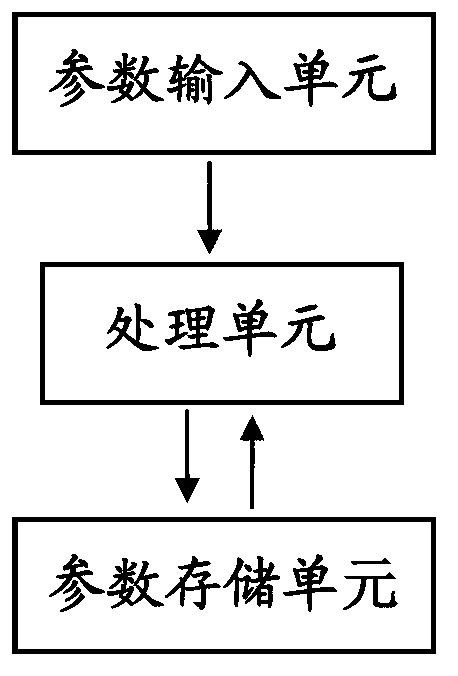

Device and method for grade evaluation of traditional Chinese medicine decoction pieces

InactiveCN103345720AAccurate judgmentComprehensive inspectionData processing applicationsTraditional medicineTraditional Chinese medicine

The invention provides a device and method for grade evaluation of traditional Chinese medicine decoction pieces. The device for grade evaluation of the traditional Chinese medicine decoction pieces comprises a parameter input unit, a parameter storage unit and a processing unit, wherein the parameter input unit is used for inputting parameters of the traditional Chinese medicine decoction pieces to be carried out grade evaluation, the parameter storage unit is used for storing the parameters of the traditional Chinese medicine decoction pieces to be carried out grade evaluation, and also stores a database of parameters of standard substances, of the traditional Chinese medicine decoction pieces, of different grades, and the processing unit carries out comparison and analysis on the obtained parameters and the parameters of the database of the standard substances, of the traditional Chinese medicine decoction pieces, of the different grades to evaluate the grades of the traditional Chinese medicine decoction pieces. The method for grade evaluation of the traditional Chinese medicine decoction pieces combines analysis indexes of various traditional Chinese medicine decoction pieces, and evaluates the grades of the traditional Chinese medicine decoction pieces through comprehensive and scientific inspection of various characteristics of the traditional Chinese medicine decoction pieces.

Owner:KANGMEI PHARMA

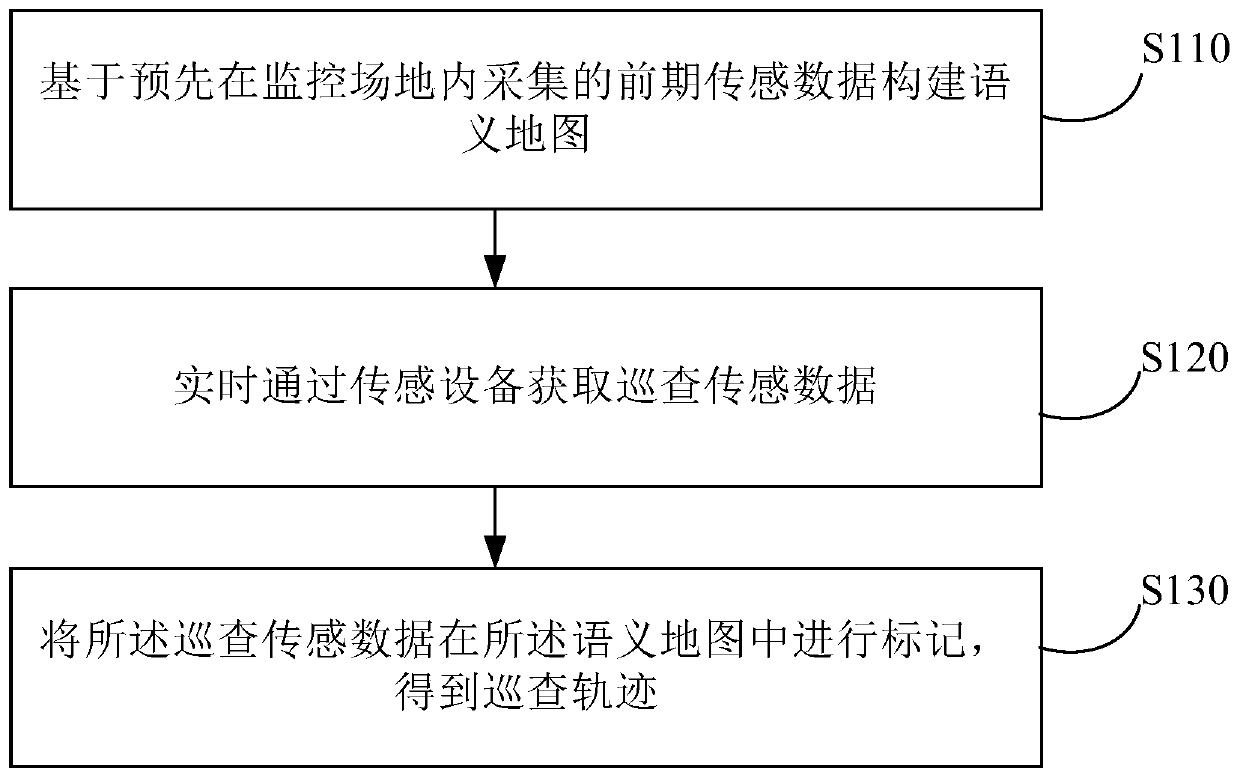

Method and device used for tracking patrol trajectory, electronic device and storage medium

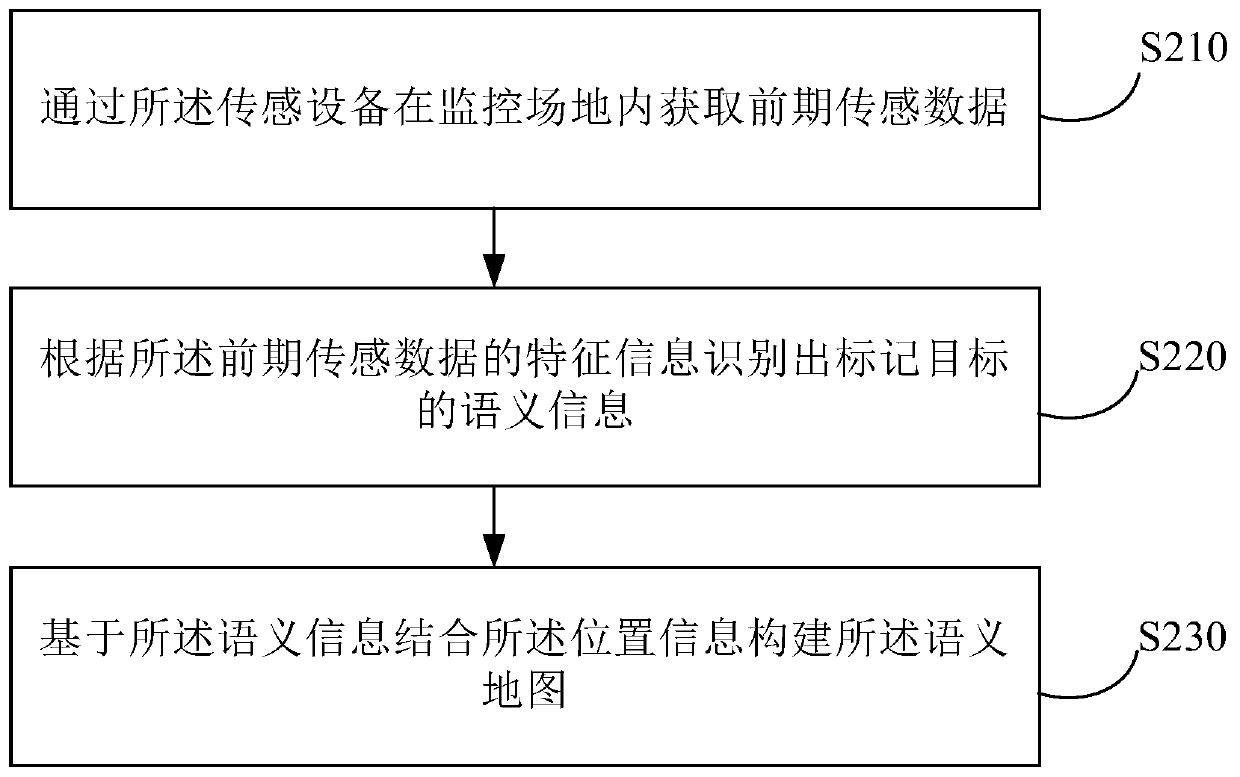

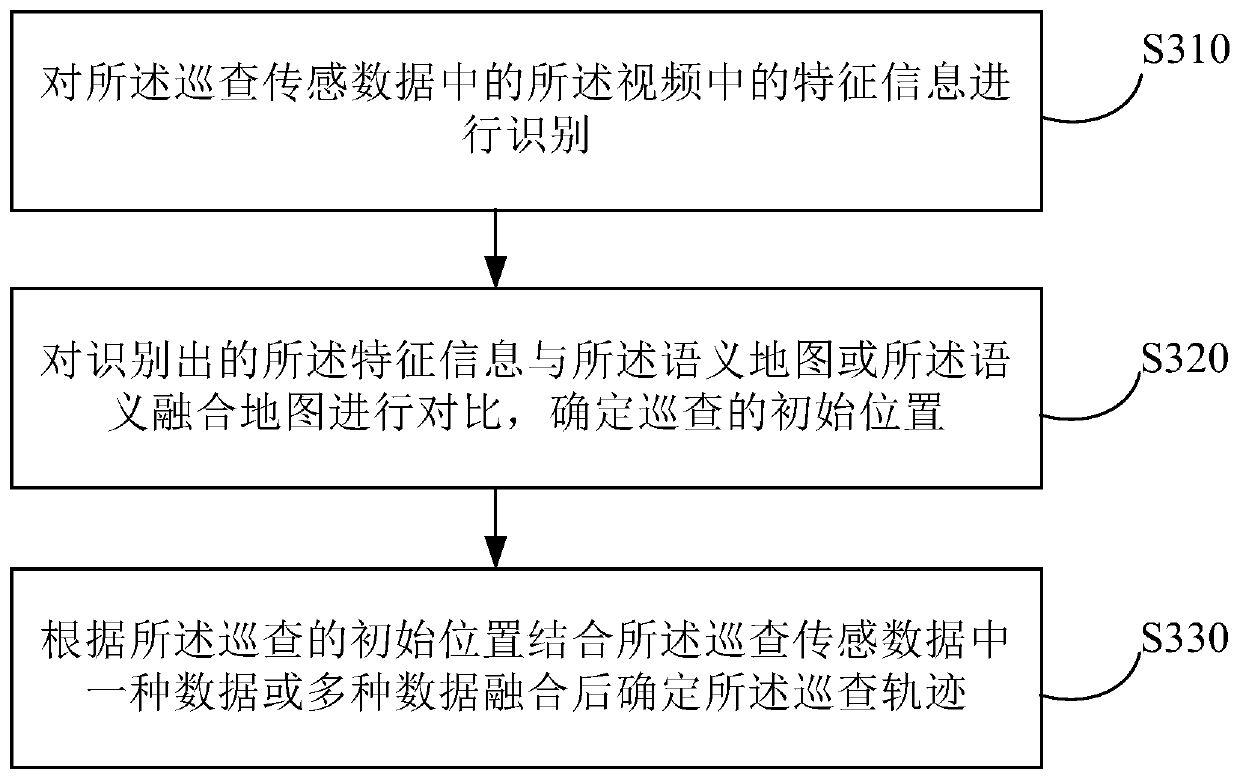

InactiveCN109916397AReduce management costsImprove inspection efficiencyNavigation by speed/acceleration measurementsElectromagnetic wave reradiationSensing dataMonitoring site

Embodiments of the invention provide a method and a device used for tracking a patrol trajectory, an electronic device and a storage medium, which relate to the technical field of a computer. The method includes the following steps: constructing a semantic map based on preliminary sensing data collected in advance in a monitoring site; acquiring patrol sensing data through a sensing device in realtime; and marking the patrol sensing data in the semantic map to obtain the patrol trajectory. According to the technical scheme of the embodiments of the invention, the patrol sensing data collectedby the sensing device is marked on the constructed semantic map to obtain the patrol trajectory, and so, the patrol efficiency can be improved, and the management cost of a patrol monitoring site isreduced; and a next patrol task can be adjusted and allocated in time according to the generated patrol trajectory, the coverage rate of a patrol can be improved, and a more comprehensive patrol is achieved.

Owner:ZEBRED NETWORK TECH CO LTD

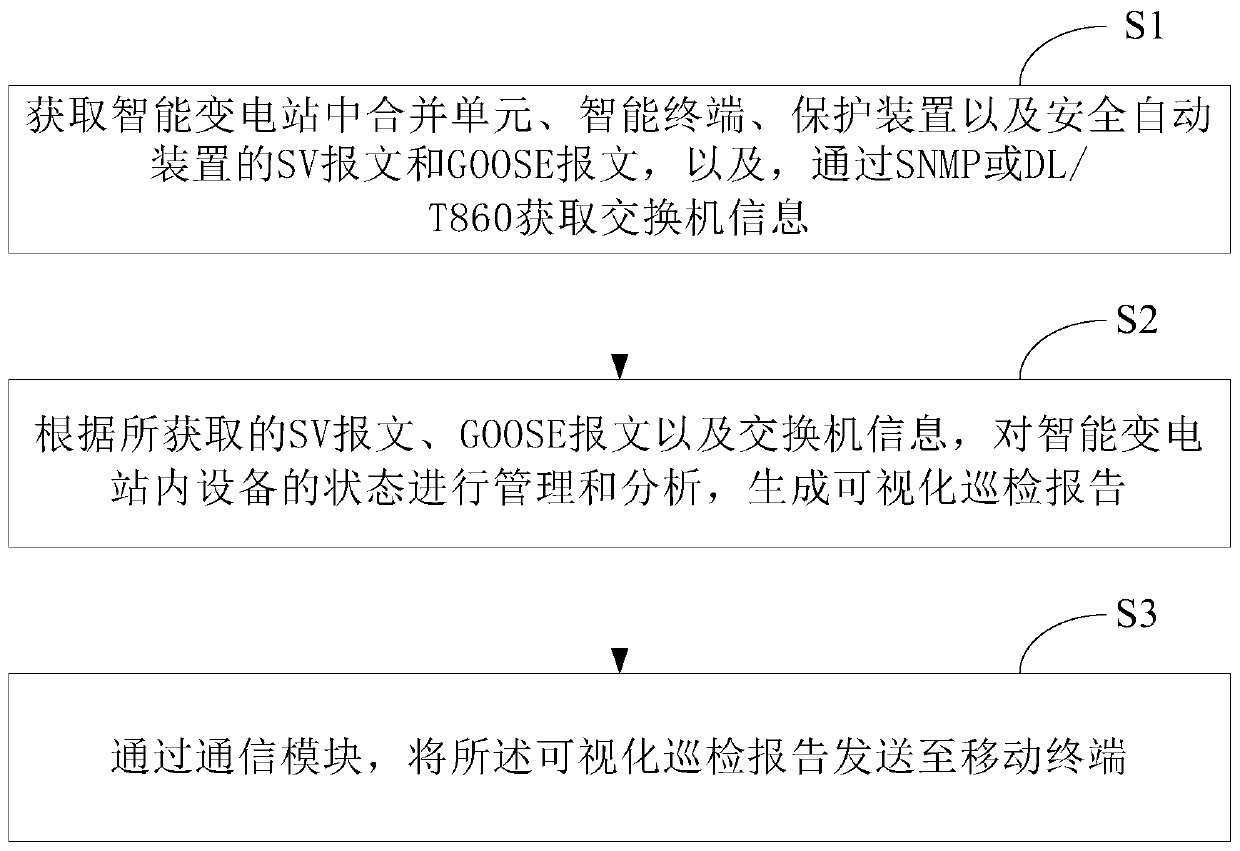

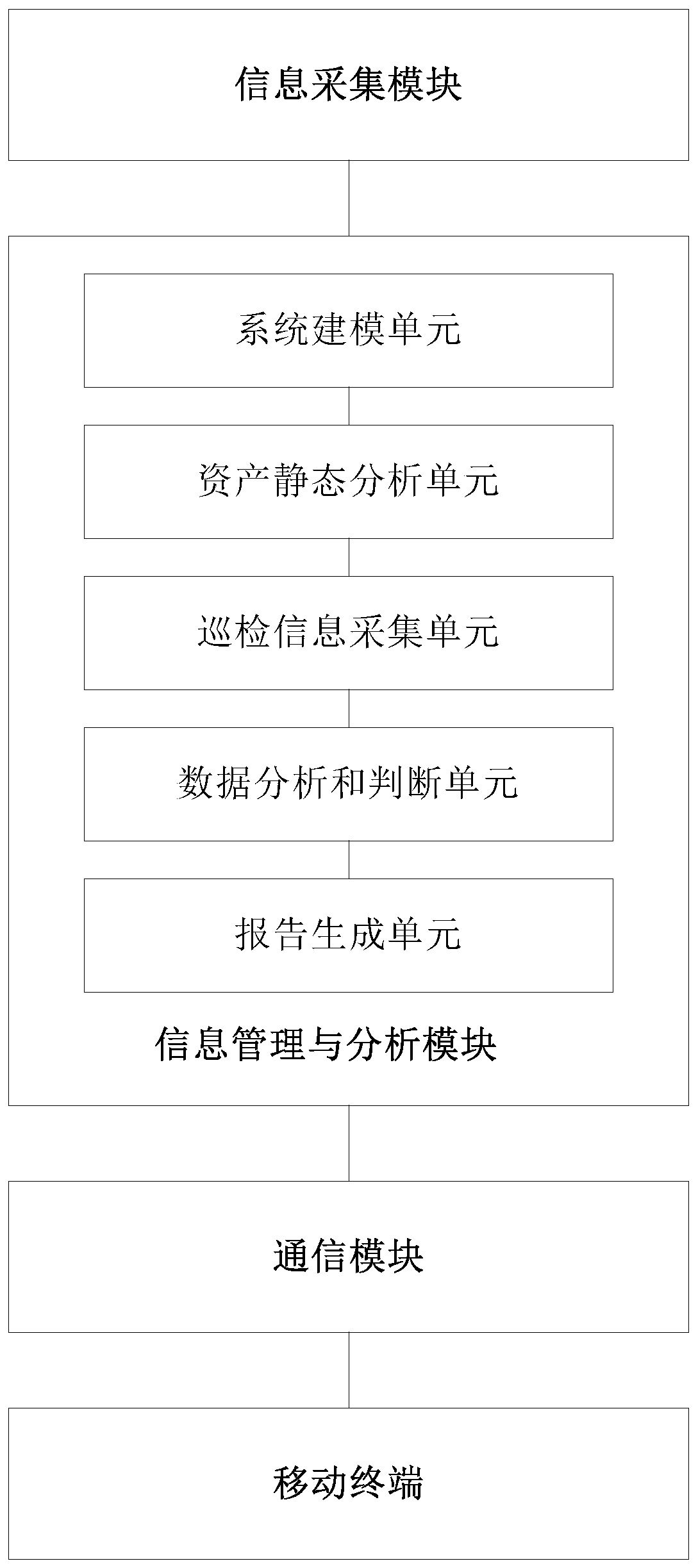

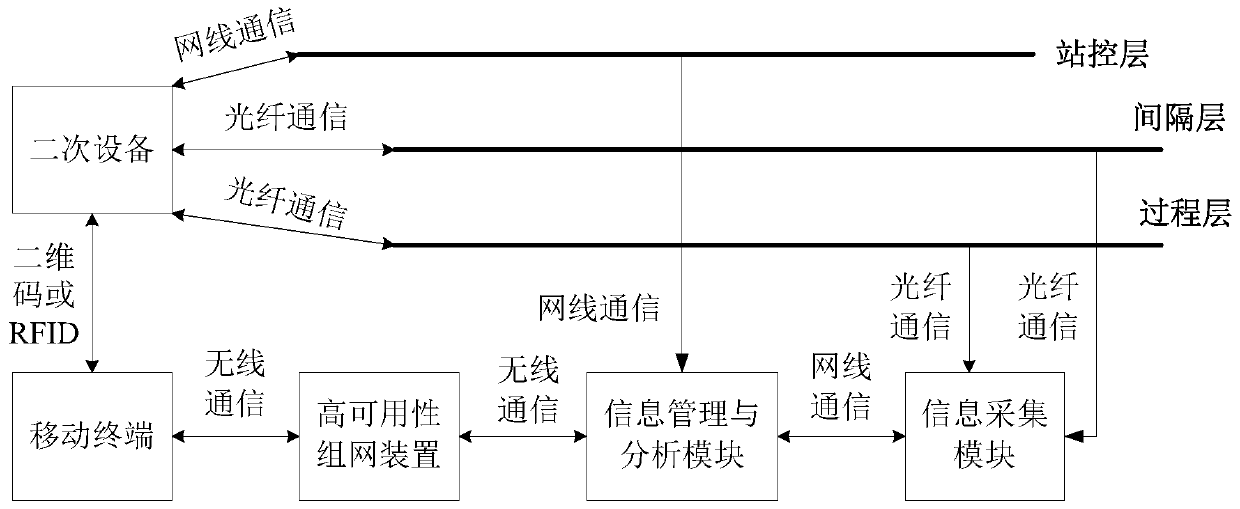

Visual inspection method and system for intelligent substation

ActiveCN111541574AImprove accuracyWide range of reportsCircuit arrangementsData switching networksSmart substationPower substation

The invention discloses a visual inspection method and system for an intelligent substation. The method comprises the following steps: firstly, acquiring related information of equipment in a processlayer and a spacer layer in the intelligent substation, then managing and analyzing the state of the equipment in the intelligent substation according to the acquired information to generate a visualinspection report, and finally, sending the visual inspection report to a mobile terminal through a communication module. The system comprises an information acquisition module, an information management and analysis module, a communication module and a mobile terminal. According to the invention, asset management, sampling management, constant value management and inspection management of the secondary device can be realized, and finally a visual report is formed. The inspection efficiency of the intelligent substation equipment and the accuracy of the inspection result are improved.

Owner:国网江苏省电力有限公司阜宁县供电分公司

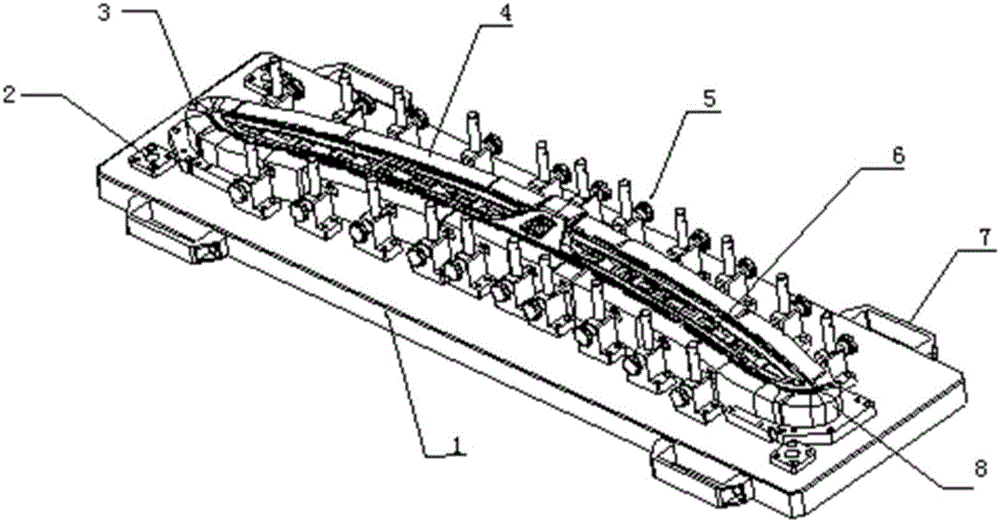

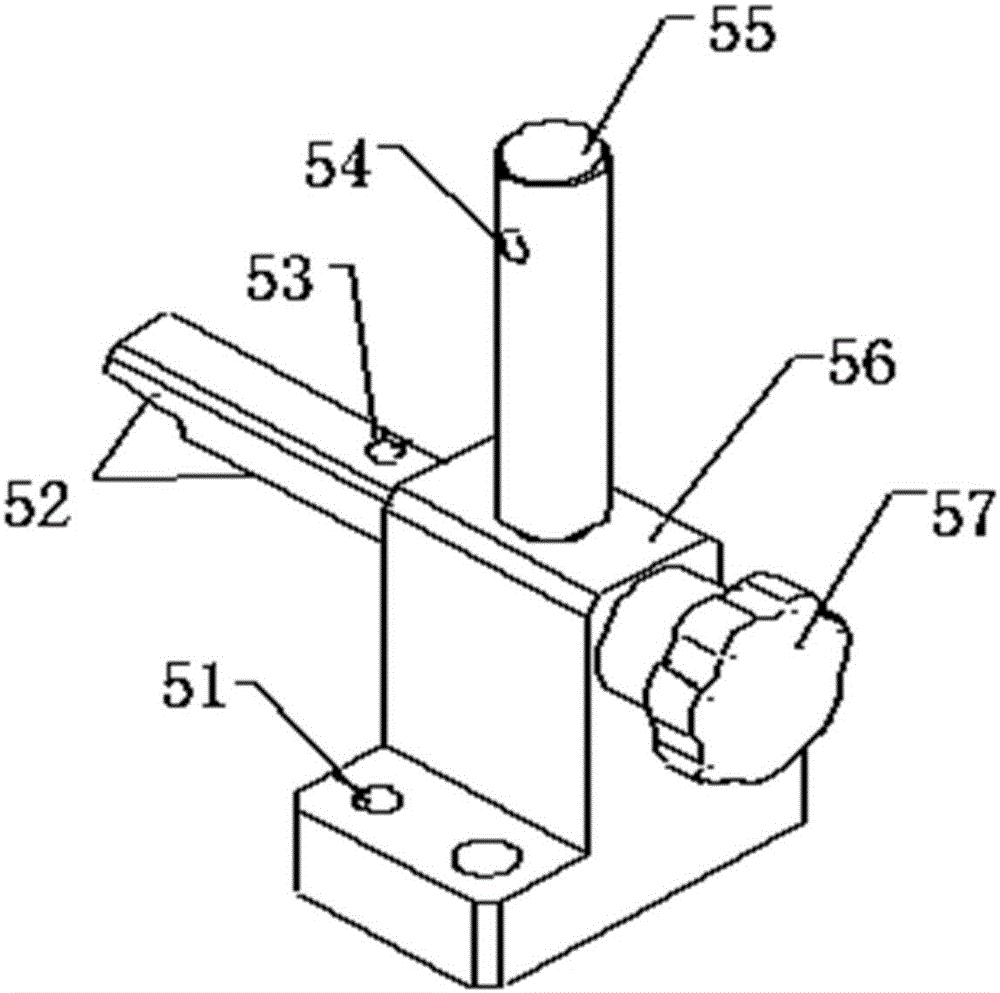

Method and device for testing automobile plastic part

PendingCN106767264AEasy to operateShort timeMechanical counters/curvatures measurementsMechanical solid deformation measurementsComputer moduleEngineering

Owner:SHANGHAI YONGXING PLASTICS

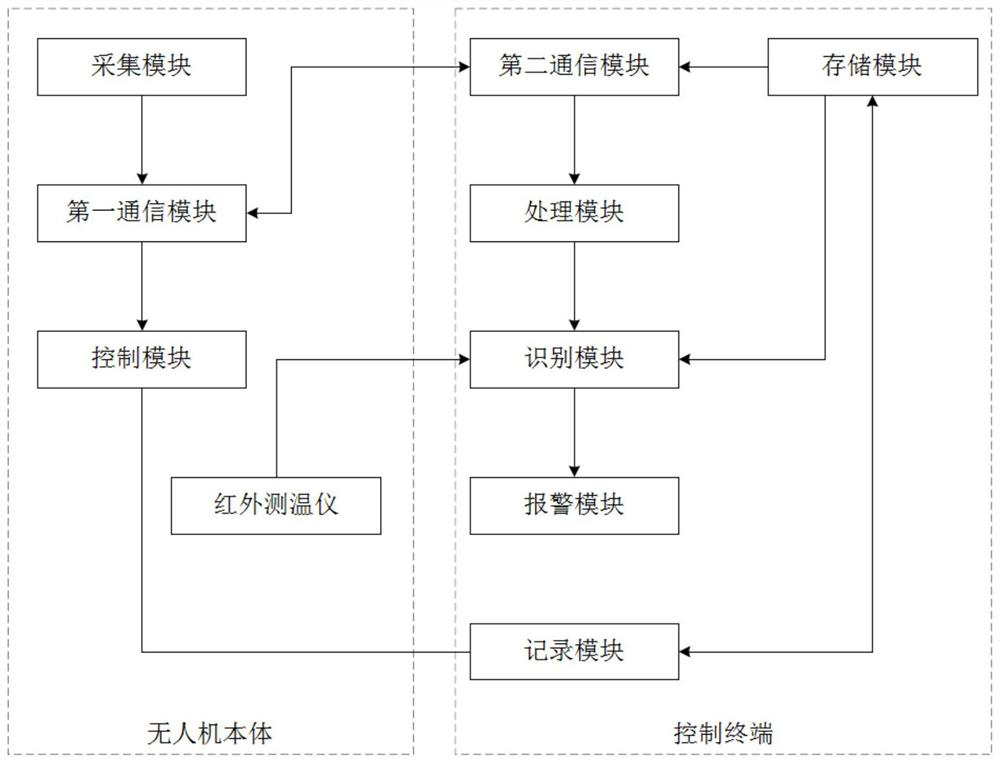

Hydrogen fuel cell oil field inspection unmanned aerial vehicle and inspection method

PendingCN112148034AImprove accuracyComprehensive inspectionScene recognitionSatellite radio beaconingInformation controlRemote control

The invention relates to the technical field of unmanned aerial vehicle equipment, and provides a hydrogen fuel cell oil field inspection unmanned aerial vehicle. The problems that an oil field imageacquired by the unmanned aerial vehicle is difficult to identify and the judgment accuracy of an abnormal condition of an oil field is reduced are solved. The hydrogen fuel cell oil field inspection unmanned aerial vehicle comprises an acquisition module, a processing module, a recognition module, an alarm module, an operation control module, a control module, a recording module and a first communication module; the acquisition module is used for acquiring the oil field image; the processing module is used for processing the oil field image; the recognition module is used for recognizing the processed oil field image; the alarm module is further used for sending a troubleshooting prompt when identifying that the oil field image is abnormal; the operation control module is used for receiving the manual remote control information, and the control module controls a unmanned aerial vehicle body to fly according to the manual remote control information; the recording module is used for recording a flight pause point at the current moment; and the first communication module is further used for receiving the checking confirmation information, and after the confirmation information is received, the control module controls the unmanned aerial vehicle body to return to the flight pause point and fly according to a preset path.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

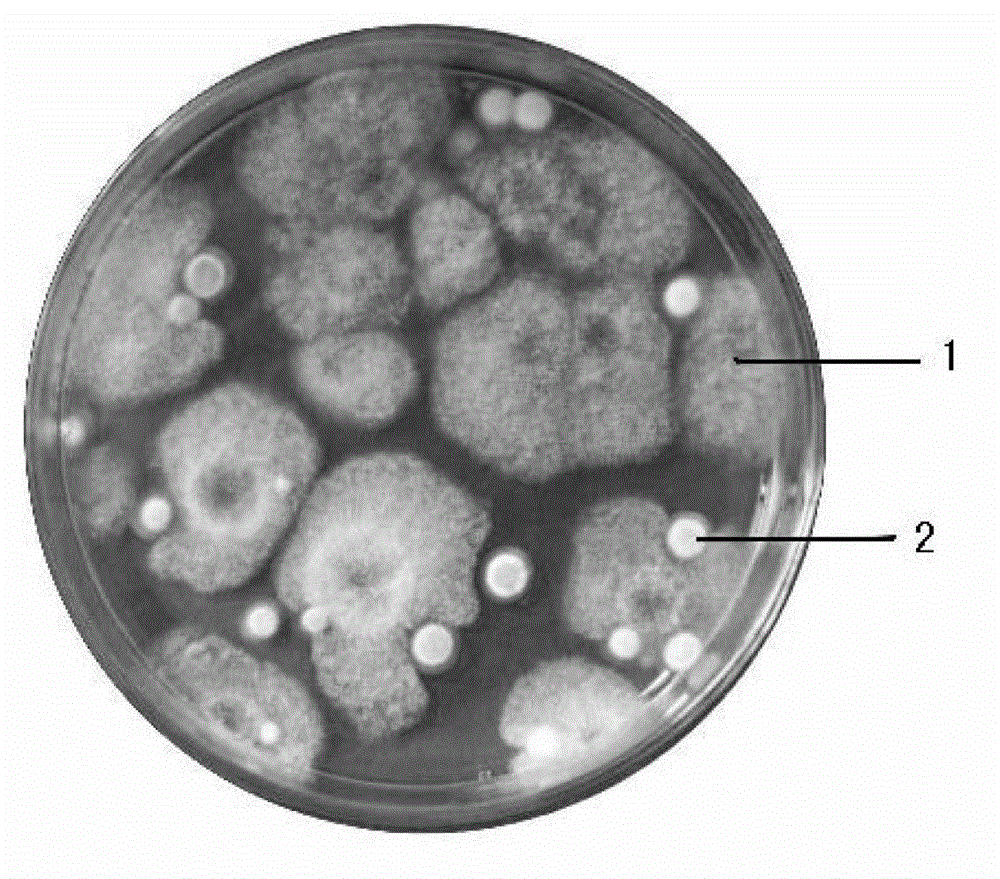

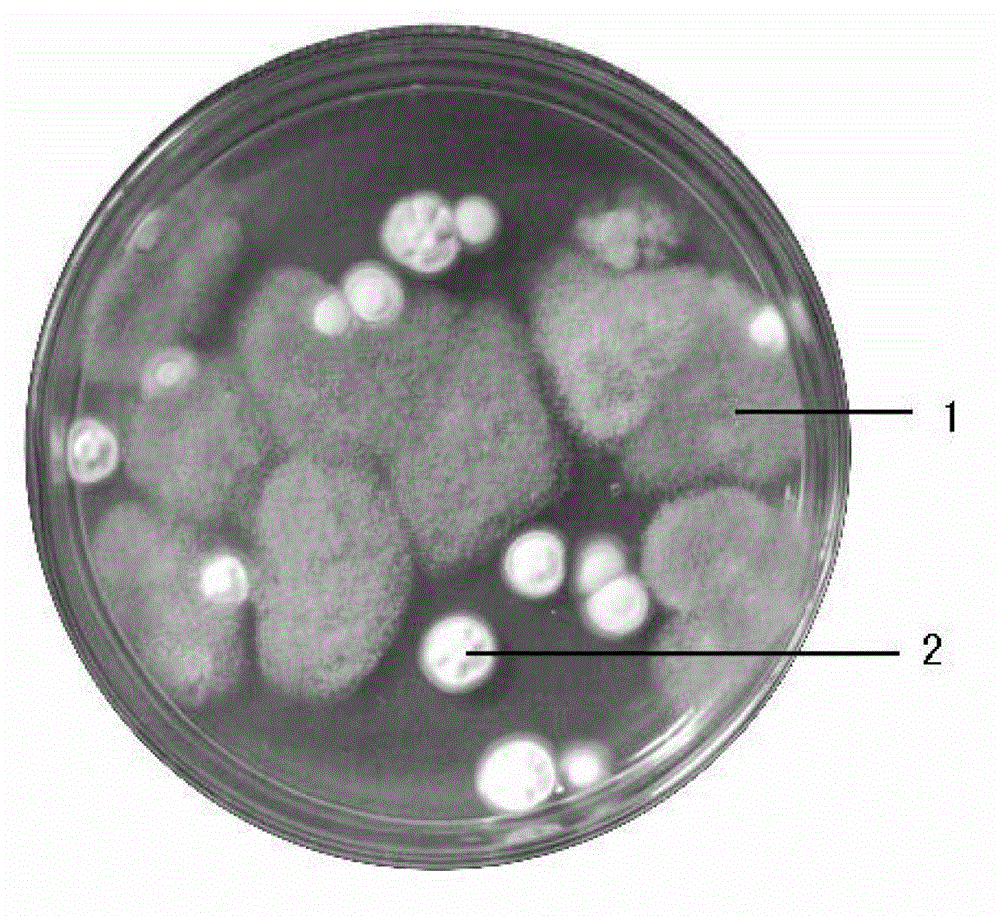

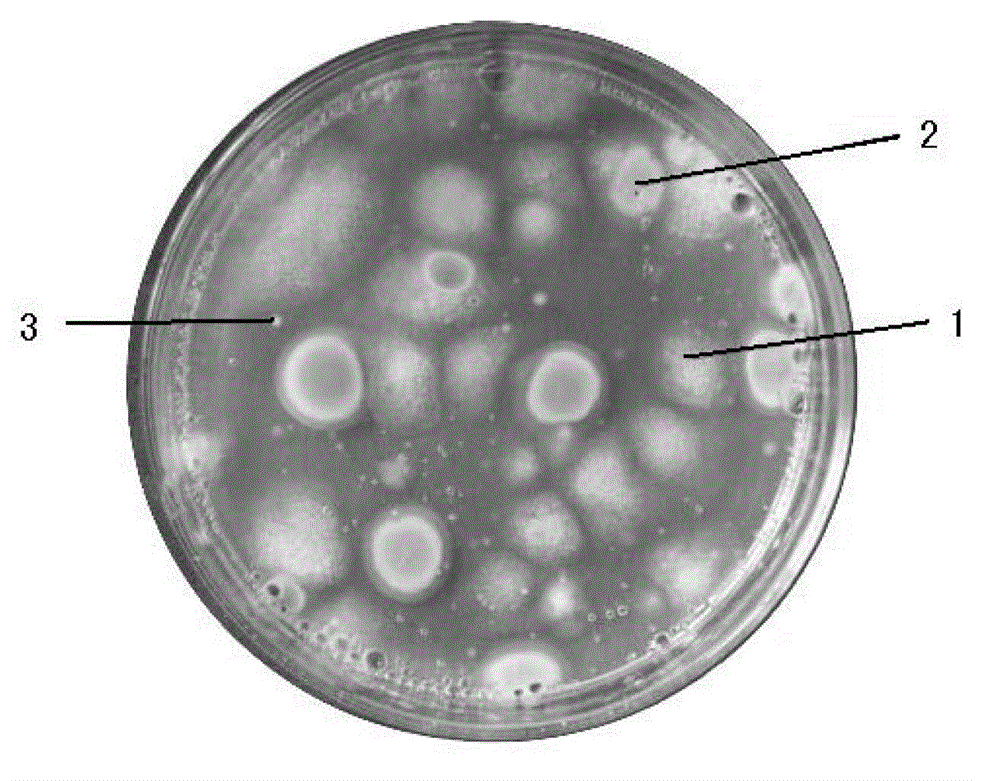

Medium for mold quantity examination and preparation and application thereof

ActiveCN102943105AQuantity results are accurateComprehensive inspectionMicrobiological testing/measurementTobacco productMaterials science

The present invention discloses a medium for mold quantity examination and application thereof. The medium for mold quantity examination of the present invention is a medium of NaCl added with potato dextrose agar having a concentration of 10-50g / 1000ml. The medium for mold quantity examination does not affect the general mold growth in tobacco and tobacco products, and also meets the needs of growth of the mold with a xerophilous characteristic, and is especially suitable for mold quantity examination in tobacco and tobacco products.

Owner:SHANGHAI TOBACCO GRP CO LTD

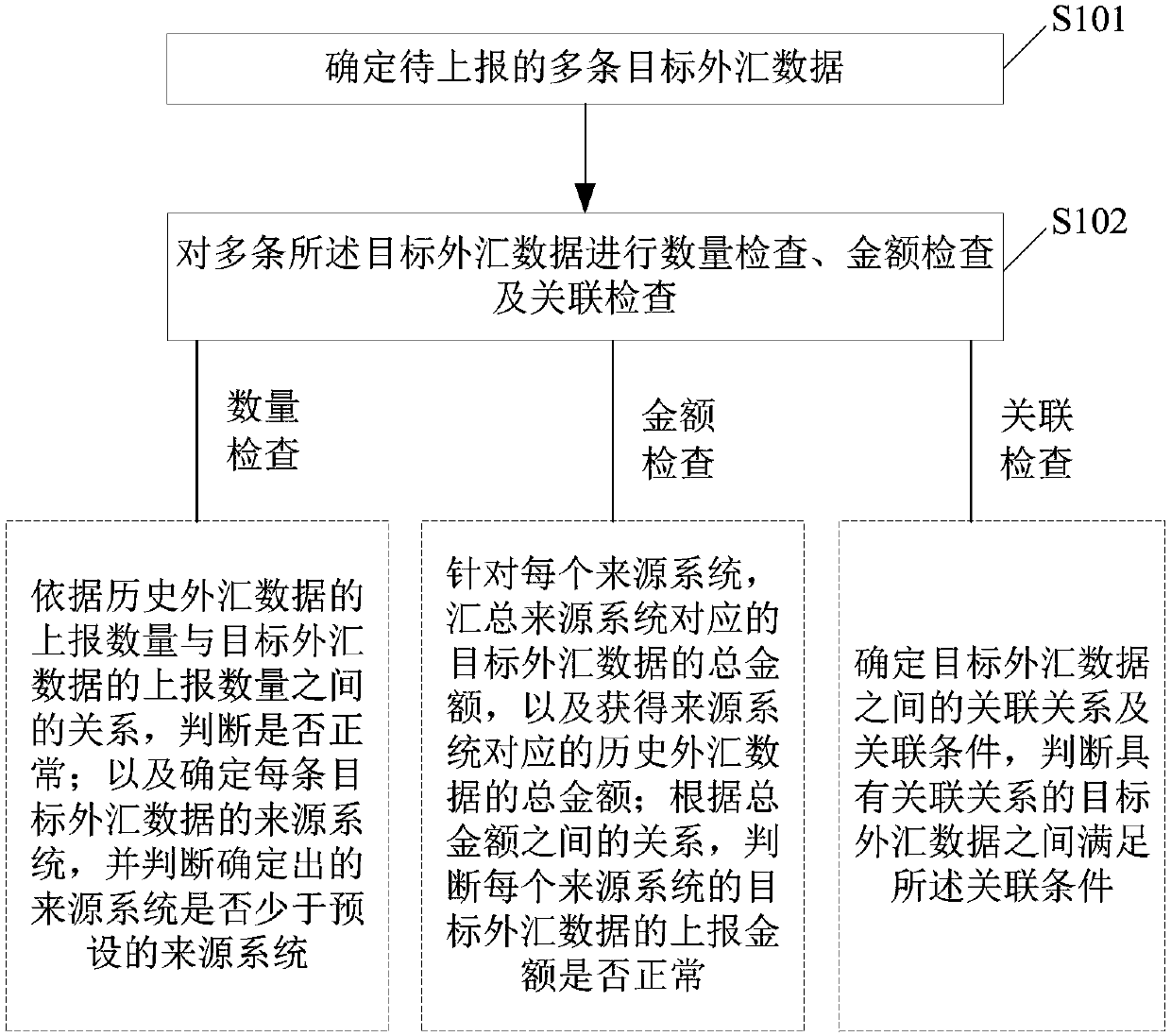

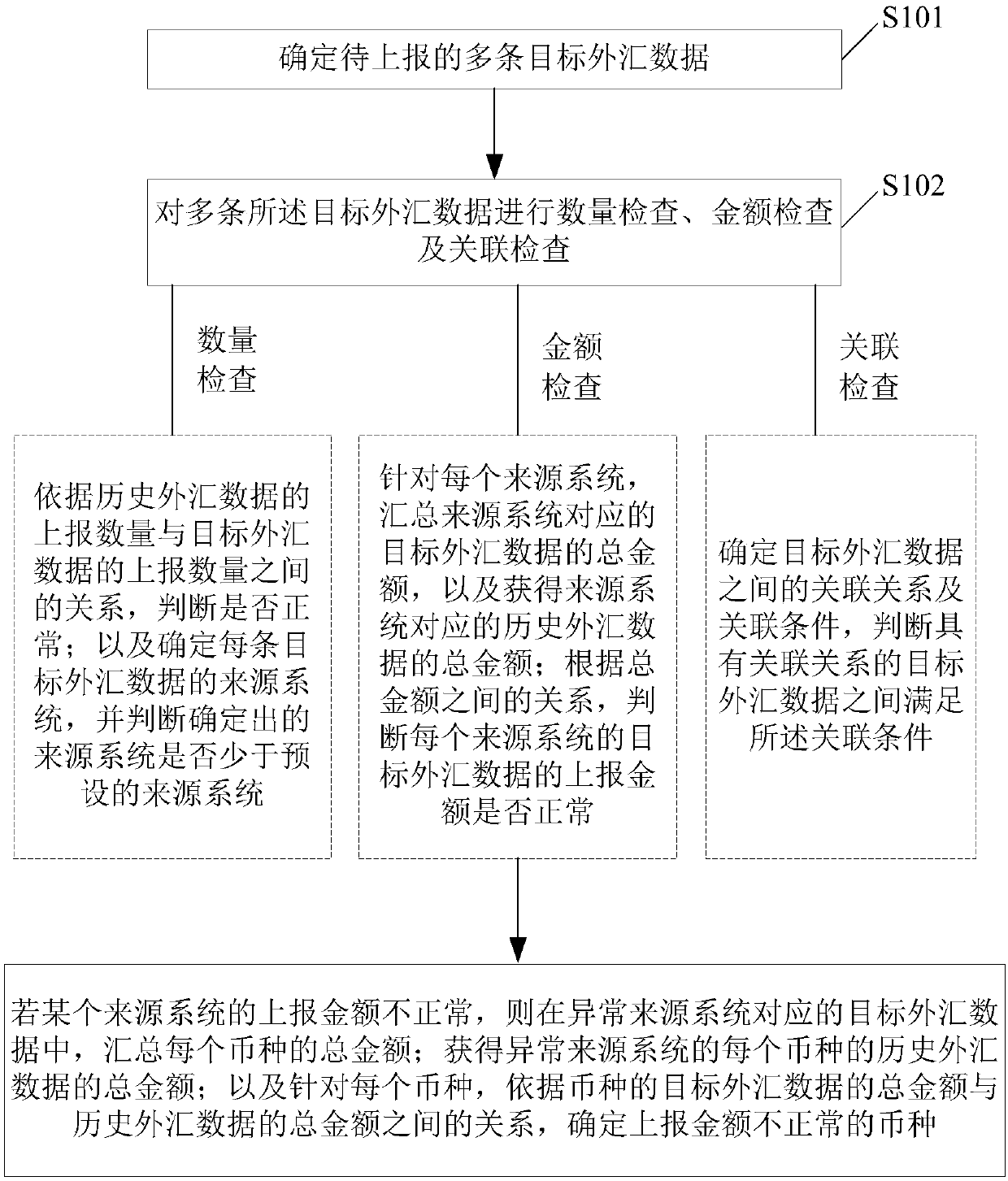

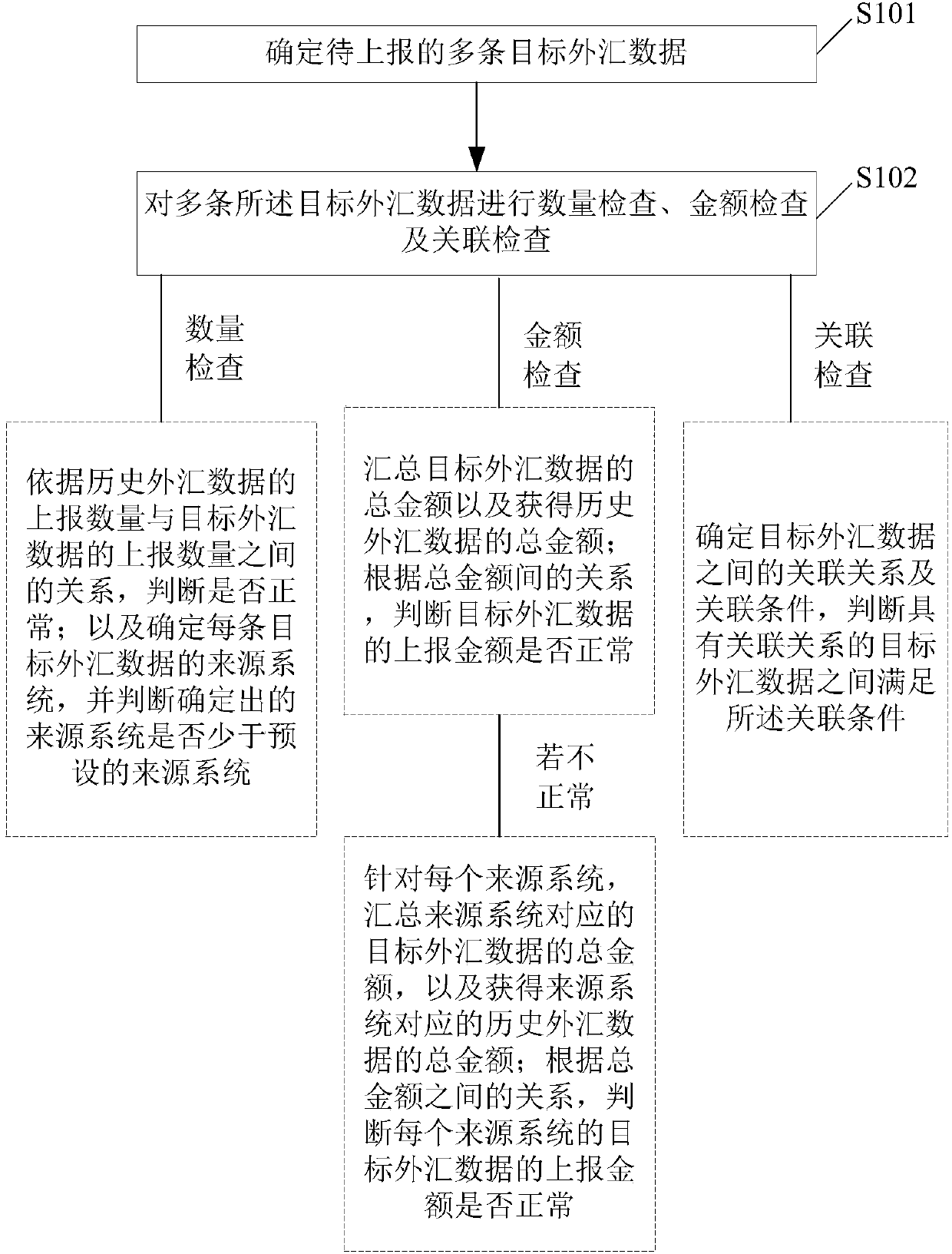

Bank foreign exchange data supervision method and device

The application provides a bank foreign exchange data supervision method. According to the method, several to-be-reported foreign exchange data are acquired, and at least three aspects of inspection,including inspection of the aspect of quantity, inspection of the aspect of amount and inspection of the aspect of correlation, are respectively performed on the foreign exchange data, wherein in theinspection of the aspect of quantity, whether abnormity exists in comparison of the quantity of to-be-reported foreign data with history of the past and whether a system missed in reporting exists areinspected; in the inspection of the aspect of amount, whether abnormity exists in comparison of the total amount of foreign exchange data reported by each system with the total amount of the foreignexchange data reported by the system in the past is inspected; and in the inspection of the aspect of correlation, whether abnormity exists in the foreign exchange data having a correlation relationship is inspected. Visibly, the bank foreign exchange data supervision method disclosed by the invention can inspect the foreign exchange data in the aspects of quantity, amount and correlation relationship, inspection contents are more comprehensive, various possible errors of the foreign exchange data can be found, and the accuracy and the integrity of the reported data can be improved.

Owner:BANK OF CHINA

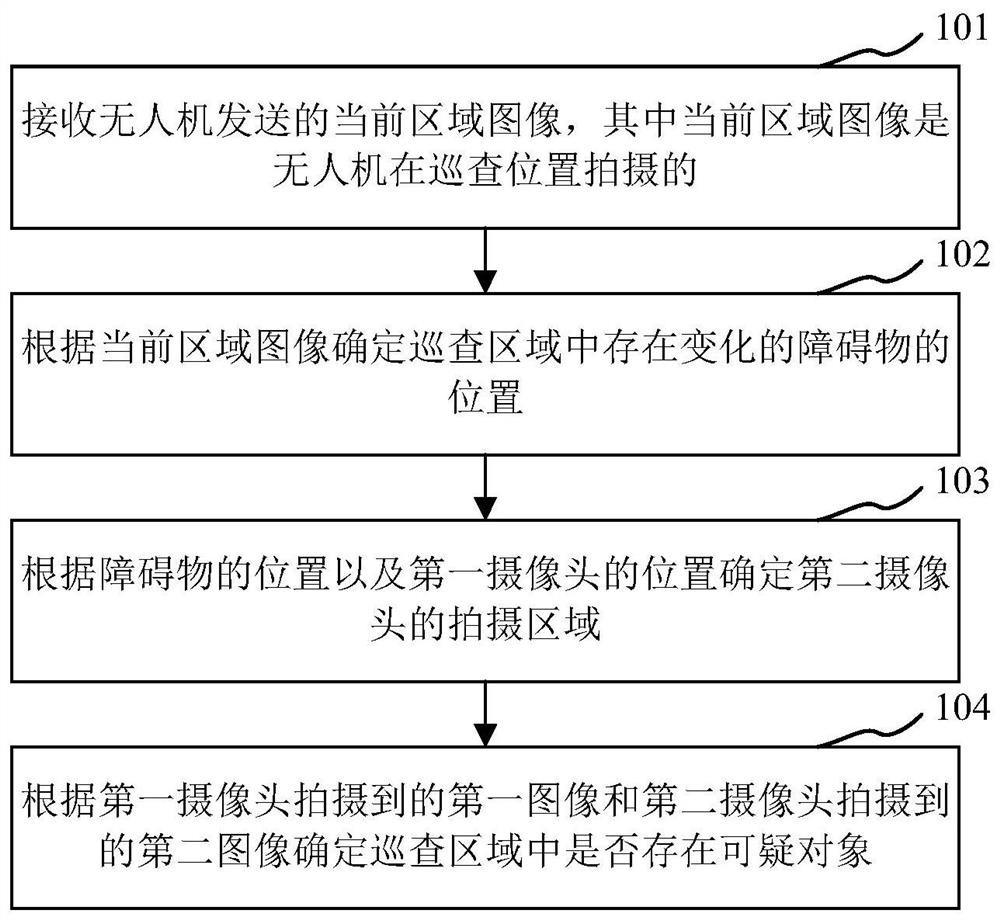

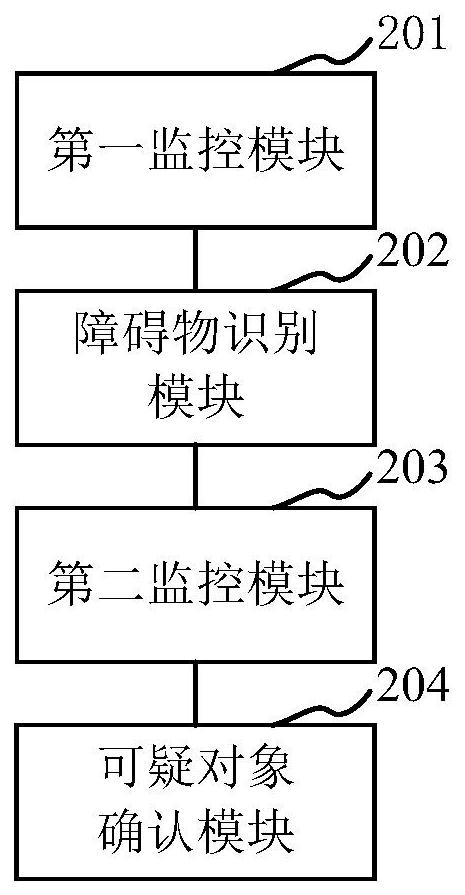

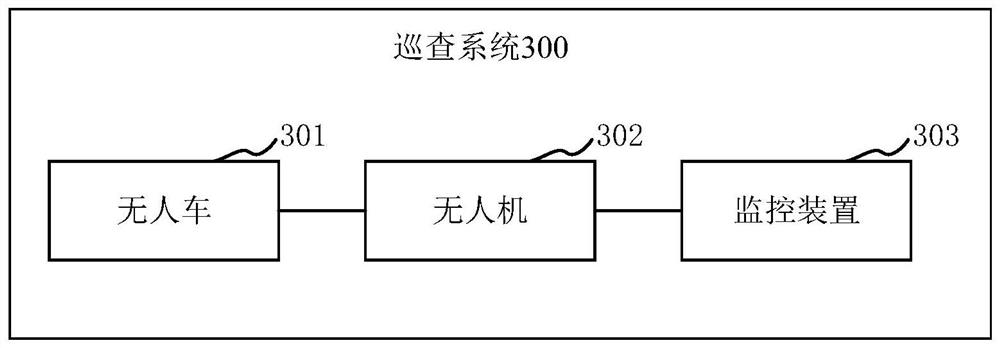

Unmanned aerial vehicle-based patrol method and patrol system and processor

PendingCN112650296AComprehensive inspectionPosition/course control in three dimensionsUncrewed vehicleSurveillance camera

The embodiment of the invention provides a method and system used for performing patrol based on an unmanned aerial vehicle,and storage medium, a processor and a computer program product. A patrol area is provided with a first camera; and an unmanned vehicle comprises a second camera. The method comprises the steps that: a current area image sent by the unmanned aerial vehicle is received, wherein the current area image is shot by the unmanned aerial vehicle at a patrol position; the position of a changed obstacle in the patrol area is determined according to the current area image; a shooting area of the second camera is determined according to the position of the obstacle and the position of the first camera; whether a suspicious object exists in the patrol area or not is determined according to a first image shot by the first camera and a second image shot by the second camera. The patrol area is recognized and monitored by combining the unmanned aerial vehicle, the unmanned vehicle and the monitoring camera, and patrol can be conducted more comprehensively.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

Identity card quality inspection device and using method thereof

PendingCN110501351AGuaranteed continuous transmissionRealize continuous detectionOptically investigating flaws/contaminationSortingSide informationControl system

The invention discloses an identity card quality inspection device. A card pushing plate in a card pushing mechanism is connected with a card pushing motor through a card pushing connecting plate. Card pushing slide rails are arranged on front and rear sides of the card pushing plate. A card supporting plate in a card supporting mechanism is connected with a lifting motor through a rising rod anda card supporting connecting plate. A U-shaped card supporting clamping plate in a turnover mechanism is arranged in the middle of the card supporting plate. A conveyor belt, a short rotating shaft, along rotating shaft and an overturning motor are connected. A bowl lamp, an annular lamp, a coaxial lamp and a camera in an image acquisition component are arranged right above the card supporting plate. A card distribution mechanism is located at a left end of the card pushing sliding rails, a card placing groove is located at a right end of the card pushing sliding rails, a card reader is located between the card placing groove and the card supporting plate. And a main control system is connected with the card pushing motor, the lifting motor, the overturning motor, a card sending motor, the camera and the card reader. Appearance quality of an identity card is determined and identity card printing information and chip storage information are verified by identifying front and reverse side information of the identity card, a structure is simple, efficiency is high, and accuracy is high too.

Owner:QINGDAO TONGCHAN SOFTWARE TECH

Textile abrasion resistance testing machine

ActiveCN113702163AQuick fixComprehensive inspectionInvestigating abrasion/wear resistanceAir pumpSlide plate

The invention provides a textile abrasion resistance testing machine, and the testing machine comprises a rack; an unwinding roller and a winding roller are installed on the rack, a sliding plate which can move up and down and is located between the unwinding roller and the winding roller is installed on the rack in a sliding mode, and fixed rollers are fixedly connected to the two feet of the bottom of the sliding plate. A plane grinding mechanism, a turning grinding mechanism and an air pumping mechanism are sequentially mounted on the side wall of the sliding plate from bottom to top, and a curved surface grinding mechanism is mounted on one side of the air pumping mechanism; the plane grinding mechanism comprises a rotatable rotating column, a connector is mounted at the bottom of the rotating column through a clutch, and four pneumatic telescopic mounting plates are fixed to the connector in the circumferential direction. The testing machine can be used for testing in a plane state, a curved surface state and a turning state, can also be used for testing in multiple directions in a rotating direction, a longitude direction and a latitude direction in the plane state, and is more comprehensive in abrasion resistance inspection and comprehensive in data.

Owner:南通好心情家用纺织品有限公司

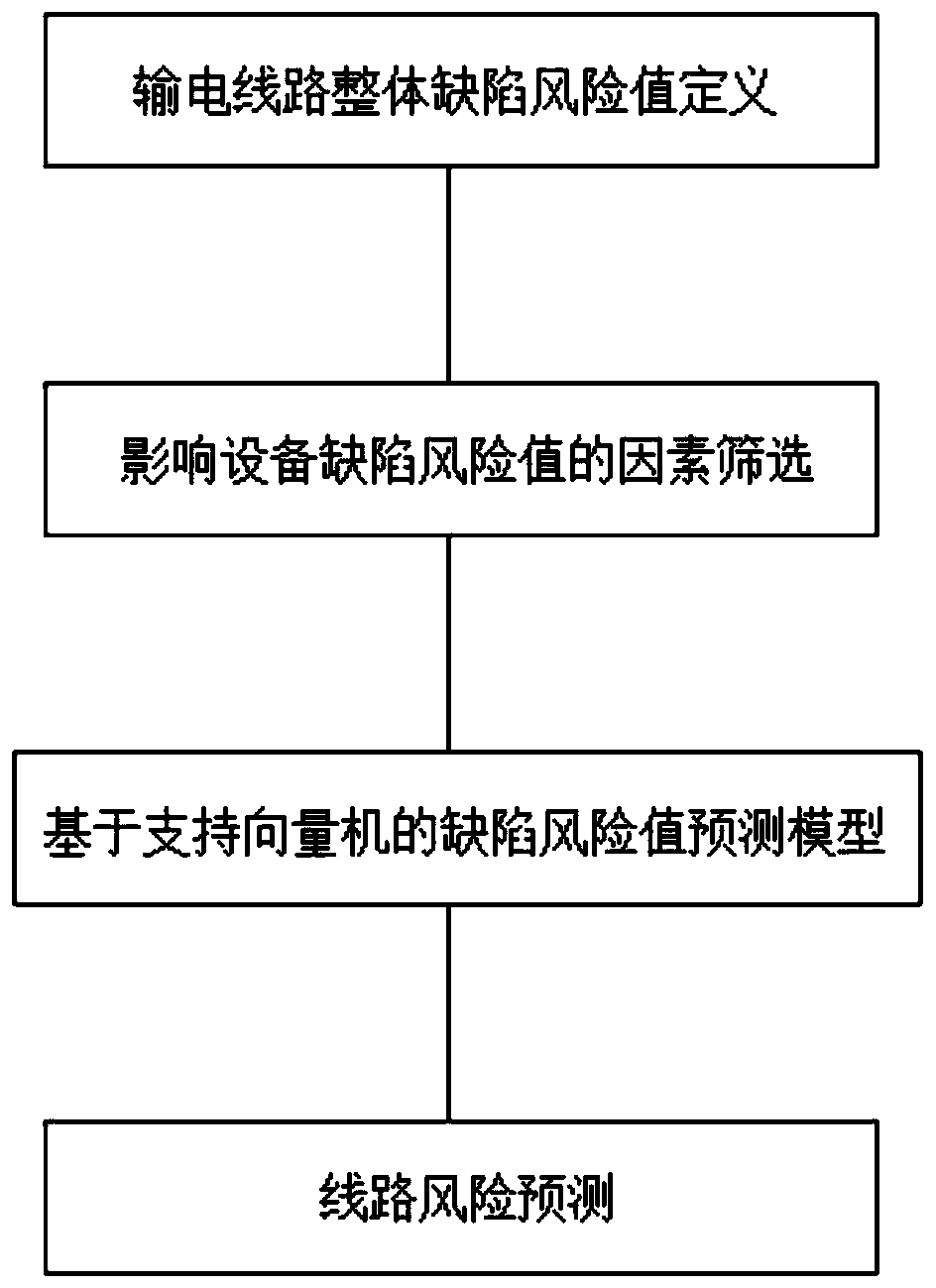

Power transmission line defect risk modeling and prediction method based on support vector machine

PendingCN110533213ADefect status is accurate and reasonableAvoid training speedKernel methodsForecastingSupport vector machineCorrelation coefficient

The invention discloses a power transmission line defect risk modeling and prediction method based on a support vector machine, and the method comprises the steps: firstly enabling a power transmission line to be subdivided into a plurality of parts, and defining a defect risk value as an evaluation index of a line defect condition under the condition of considering the number of defects and the severity degree of the defects; secondly, screening out important factors influencing the defect risk value of each part through correlation coefficients, introducing a support vector machine machine learning method, and predicting the future defect risk value of the line by utilizing the advantage that the small sample learning problem can be effectively solved. The size of the defect risk prediction value reflects the defect condition of the power transmission line in the future, and an important reference can be provided for the work of related departments.

Owner:GUANGDONG UNIV OF TECH

Method for checking safety performance of single-container washing machines

InactiveCN106053112AEasy to operateImprove accuracyTesting dielectric strengthEarth resistance measurementsPower flowReliability engineering

The invention discloses a method for checking the safety performance of single-container washing machines. The method comprises the following steps: S1, appearance check; S2, test of insulation resistance; S3, voltage withstanding test; S4, grounding performance test; S5, test of leak current; S6, test of actual power; S7, test of breaking performance; S8, heating test of the washing machines; and S9, completion of the whole safety performance check of the washing machines after steps S1-S8 are completed, wherein qualified products are delivered to next procedure, whereas unqualified products are delivered to a repair line. The method for checking the safety performance of single-container washing machines is comprehensive and detailed in check contents, convenient to operate, high in test result accuracy and high in reliability of product judgment result.

Owner:ANHUI JINSHUAI WASHING MACHINE

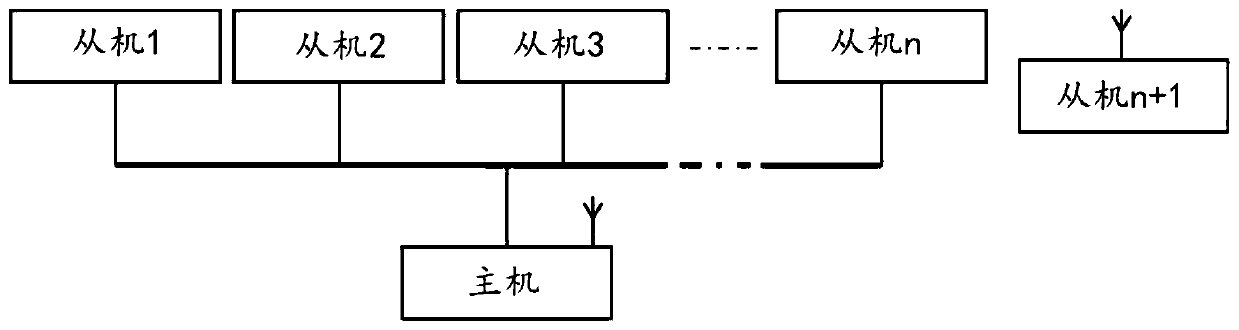

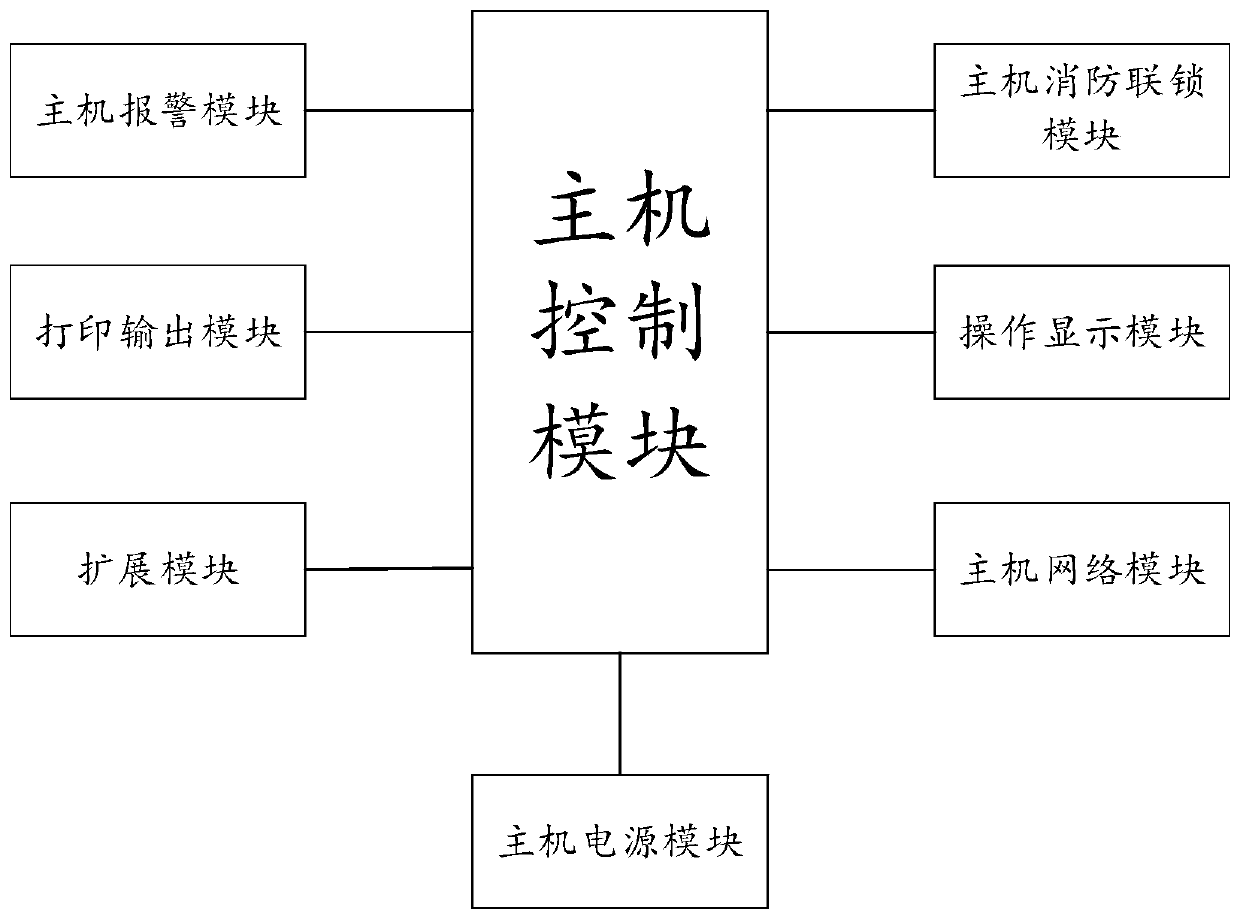

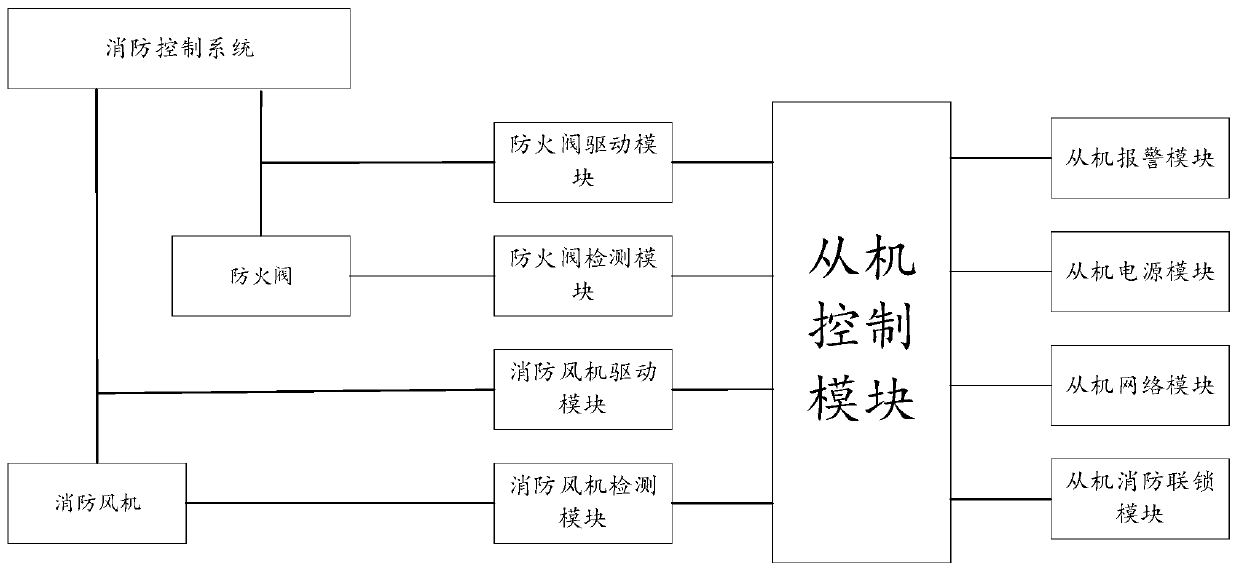

Distributed automatic fire-fighting fan inspection system

ActiveCN110319046AImprove securityImprove reliabilityPump controlNon-positive displacement fluid enginesComputer moduleEngineering

The invention provides a distributed automatic inspection system for a fire-fighting fan. According to the system, a host control module, a host fire-fighting interlock module, an operation display module, a host network module and the like are arranged on a host, an slave control module, a driving module, a detection module, a slave fire-fighting interlock module and a slave network module are arranged on a slave, so that the automatic inspection of distributed fire-fighting fans is realized. According to the system, on the basis that an original fire-fighting system is not changed, the states of the fire-fighting fans and fire-proof valves can be inspected in real time on line or off-line by adding modules, so that the problem can be found in time, remote and local abnormal alarming canbe realized, the safety and reliability of the fire-fighting system are improved, and in addition, the working modes and running parameters of the system can be set by adopting programming, so that the system is suitable for the requirements of different fire-fighting places and fire-fighting levels, the manual inspection cost is reduced, and the inspection is more comprehensive.

Owner:山东科能电气设备有限公司

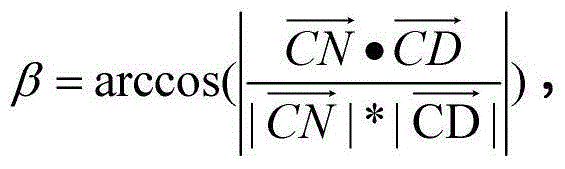

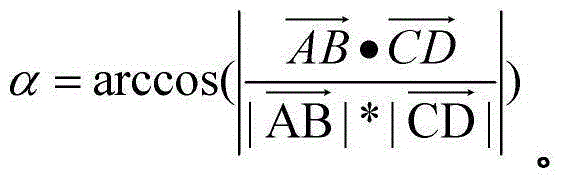

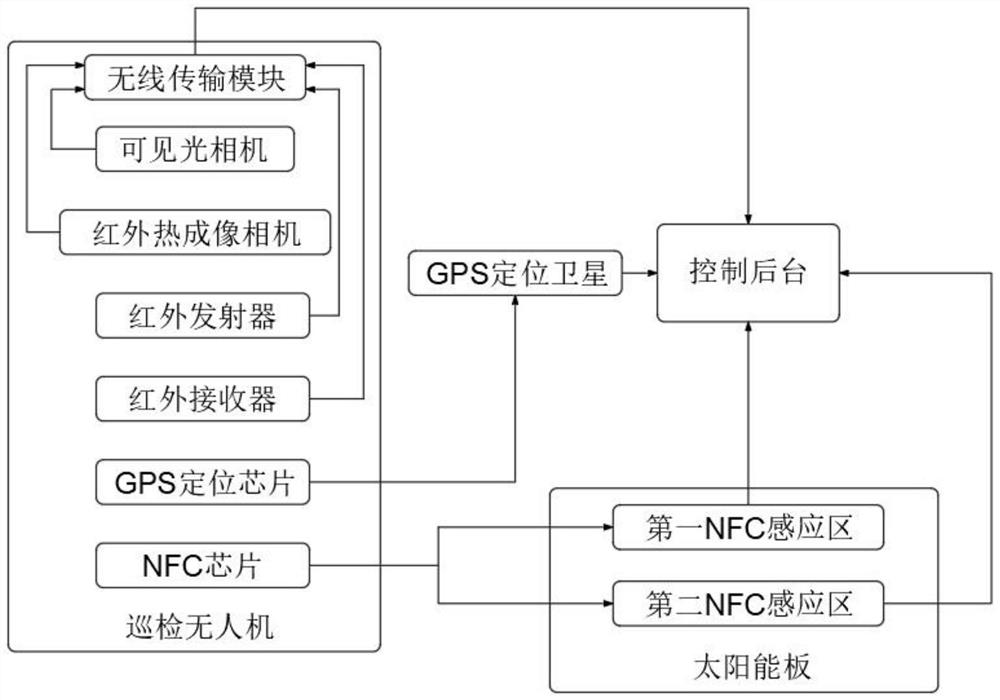

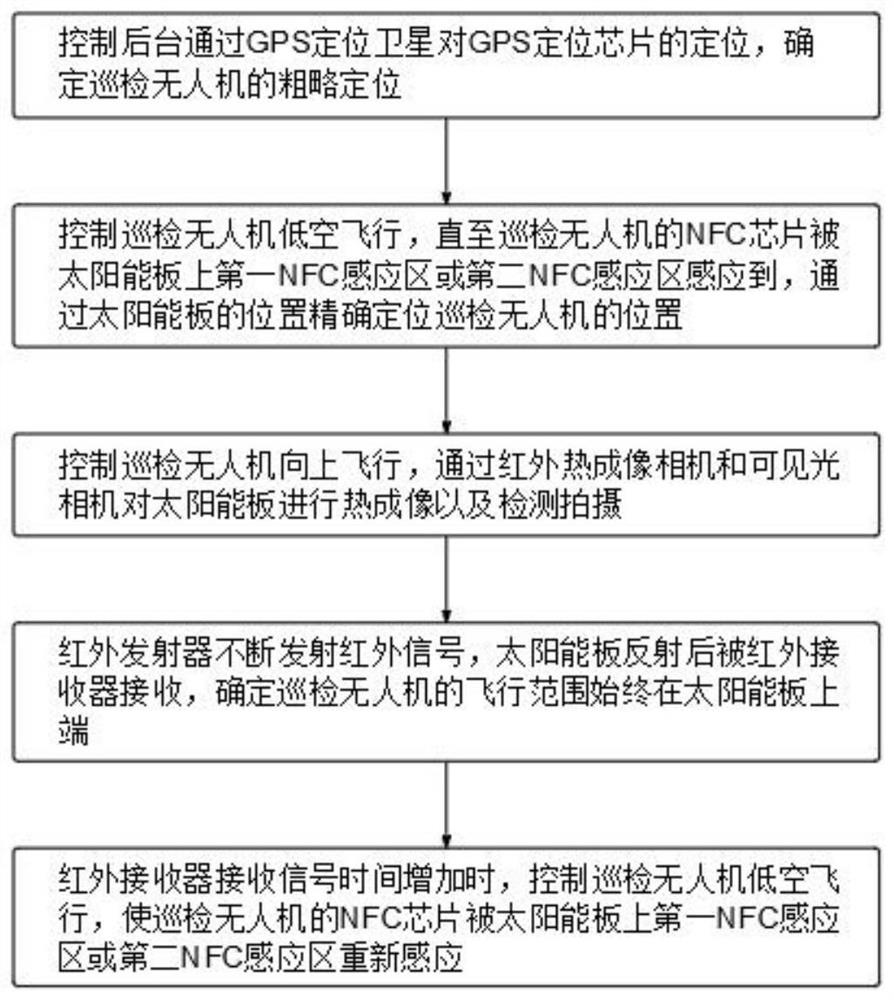

Intelligent routing inspection positioning method and system

PendingCN114186649AReduced targeting rangePrecise positioningRadiation pyrometryPhotovoltaic monitoringUncrewed vehiclePhotovoltaic power station

The invention discloses an intelligent routing inspection positioning method and system, relates to the related field of photovoltaic routing inspection positioning, and aims to solve the problem that a GPS (Global Positioning System) in the prior art is difficult to meet the positioning requirement on an occasion with a high precision requirement. And the inspection unmanned aerial vehicle is difficult to obtain the accurate position information of the corresponding solar panel in the centralized photovoltaic power station with complex regional environment and large installed capacity. The inspection unmanned aerial vehicle comprises an NFC chip, two opposite corners of the upper end surface of the solar panel are respectively provided with a first NFC induction area and a second NFC induction area, and the NFC chip is in signal induction with the first NFC induction area and the second NFC induction area; wherein the NFC chip is used for transmitting an induction signal; the first NFC sensing area is used for receiving a sensing signal of the NFC chip and feeding back the signal to a target position; and the second NFC sensing area is used for receiving a sensing signal of the NFC chip and feeding back the signal to a target position.

Owner:南京和电科技有限公司

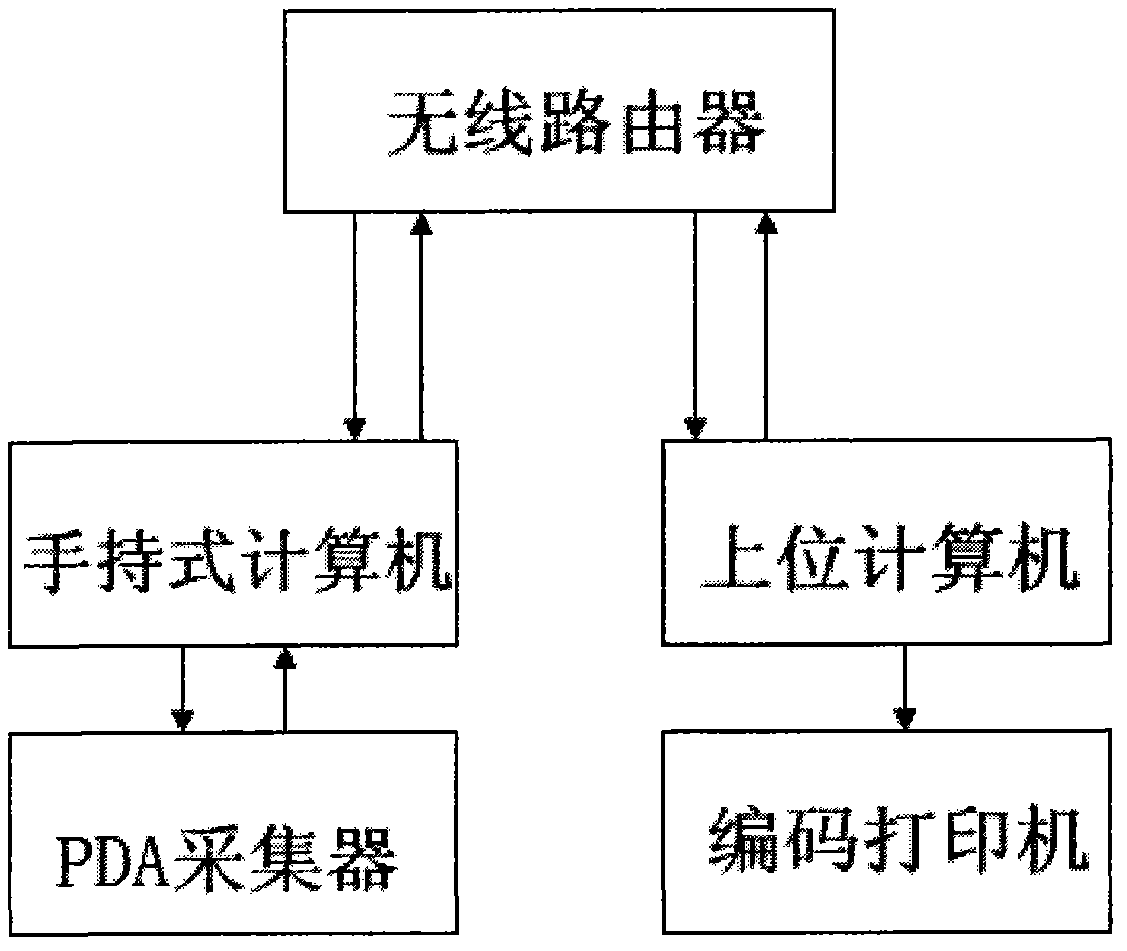

Device and method for routing inspection of electrical equipment in switching room

InactiveCN103268646AComprehensive inspectionEasy programmingRegistering/indicating working of machinesComputer hardwareWireless router

The invention discloses a device and a method for routing inspection of electrical equipment in a switching room. The device comprises a handheld PDA collector, a host computer, a wireless router, a coding printer and a handheld computer. The host computer is electrically connected to the coding printer and is connected to a wireless network. The handheld computer is electrically connected to the handheld PDA collector. The device and the method have the advantages that comprehensive routing inspection is realized; routing inspection projects are interrelated and restricted with each other; a programming process is simple and can be learned easily; operators can carry out corresponding routing inspection according to different stations and different equipment so that adaptability is strong; and a training function is obtained so that in routing inspection, operators can be subjected to equipment operation training.

Owner:QINYANG POWER INTEGRATED CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com