Method for inspecting station by inspection worker

A technology for personnel and stations, which is applied in the field of station daily inspection operations, can solve the problems of inability to conduct real-time on-site inspections of personnel's operations, damage, and inspection content that cannot be reflected, and achieve comprehensive inspections and reduce workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

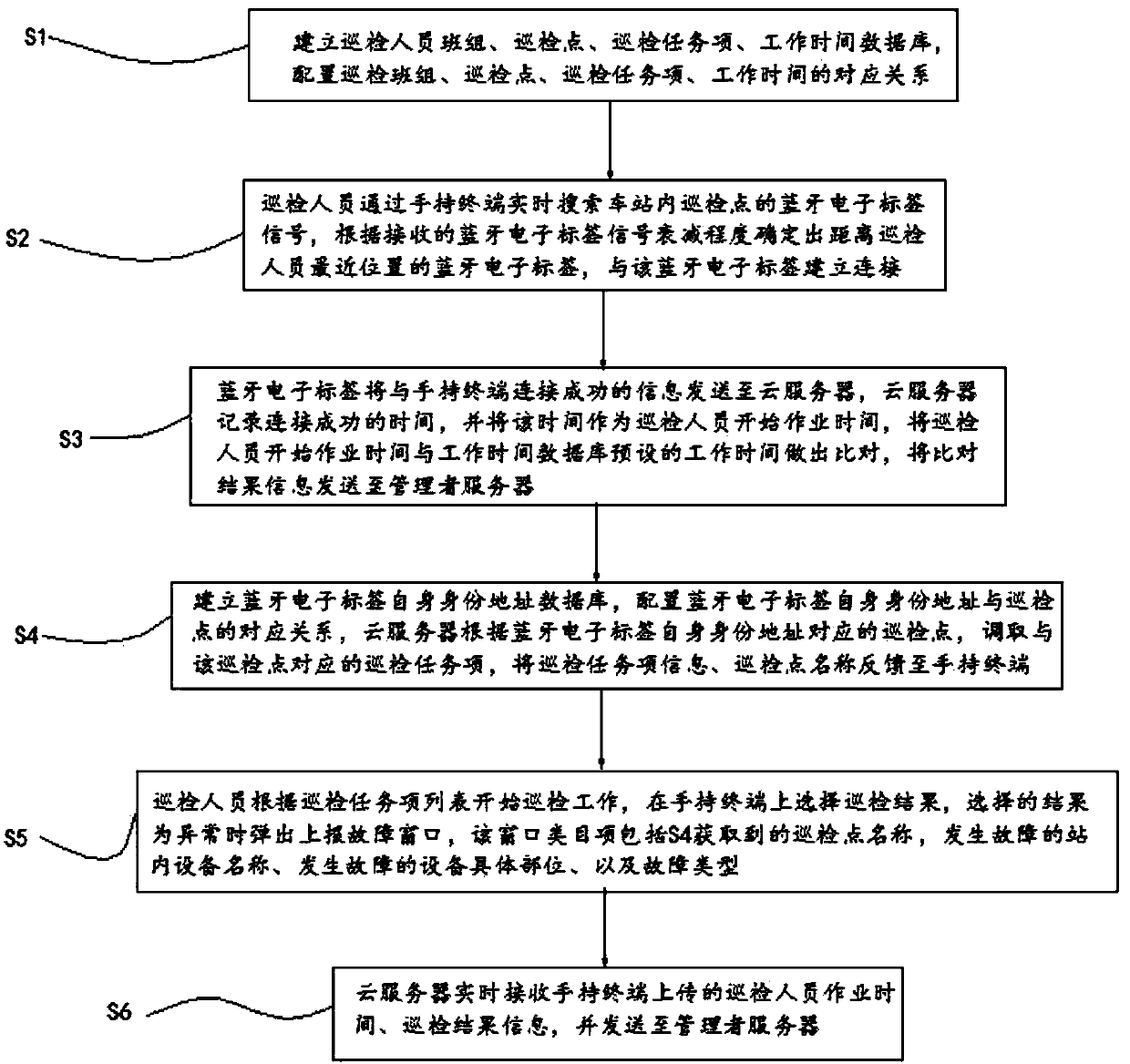

[0026] Embodiment 1: A method for inspection personnel to inspect a station disclosed by the present invention, its flow chart refers to figure 1 shown, including the following steps:

[0027] S1. Establish a database of inspection personnel teams, inspection points, inspection task items, and working hours, and configure the correspondence between inspection teams, inspection points, inspection task items, and working hours;

[0028] S2. The inspector searches for the Bluetooth electronic tag signal at the inspection point in the station in real time through the handheld terminal, determines the Bluetooth electronic tag closest to the inspector according to the attenuation degree of the received Bluetooth electronic tag signal, and establishes a connection with the Bluetooth electronic tag ;

[0029] S3. The bluetooth electronic tag sends the information about the successful connection with the handheld terminal to the cloud server, and the cloud server records the time of t...

Embodiment 2

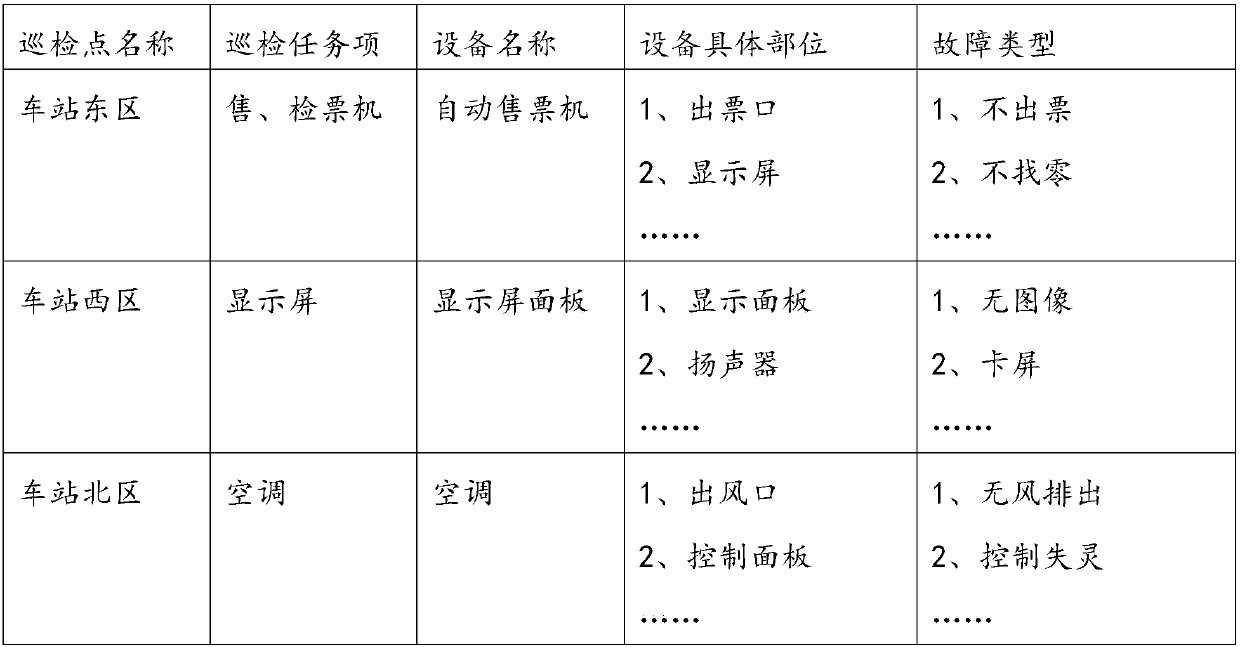

[0040] Embodiment 2: In addition to the technical solution of the present invention disclosed in Embodiment 1, in order to further optimize the present invention, the S5 includes establishing a database of fault types, configuring data on specific parts of the equipment according to the equipment in the station, and configuring inspection task items, equipment names, The corresponding relationship between the specific parts of the faulty equipment and the fault type database, for example, is shown in the following table:

[0041]

[0042] For example, the above-mentioned database can be established and the corresponding relationship configured, so that when reporting a fault, it is convenient to reduce manual input, and the corresponding device name will appear automatically in the pop-up inspection task item, and it will also be self-adaptive according to the device name The specific parts of the equipment that appear can be selected. According to the name of the equipment ...

Embodiment 3

[0047] Embodiment 3: In order to further optimize the present invention, said S5 includes configuring the time limit for resolving the fault according to the corresponding relationship between the configured device name, the specific part of the faulty device, and the fault type database.

[0048] According to the corresponding relationship between the equipment name, the specific part of the equipment where the failure occurs, the failure type database, and the time limit for solving the failure, configure the priority level for solving the failure. Generally, in the station, according to the importance of the equipment in the station, there will be an order of priority to solve the fault, but this order is generally defined by experience. The priority level of faults, so that after the inspection personnel complete the work, the station management personnel can obtain the priority to solve the fault, and then can arrange maintenance work scheduling and other arrangements, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com