Inclination detection device and method for tire durability

A technology of inclination detection and durability, applied in the direction of automobile tire testing, etc., can solve the problems of improving tire production quality, untargeted performance testing, unfavorable feedback, etc., and achieves a high level of closed-loop control and automation, and real and effective experimental conditions Targeted, improve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

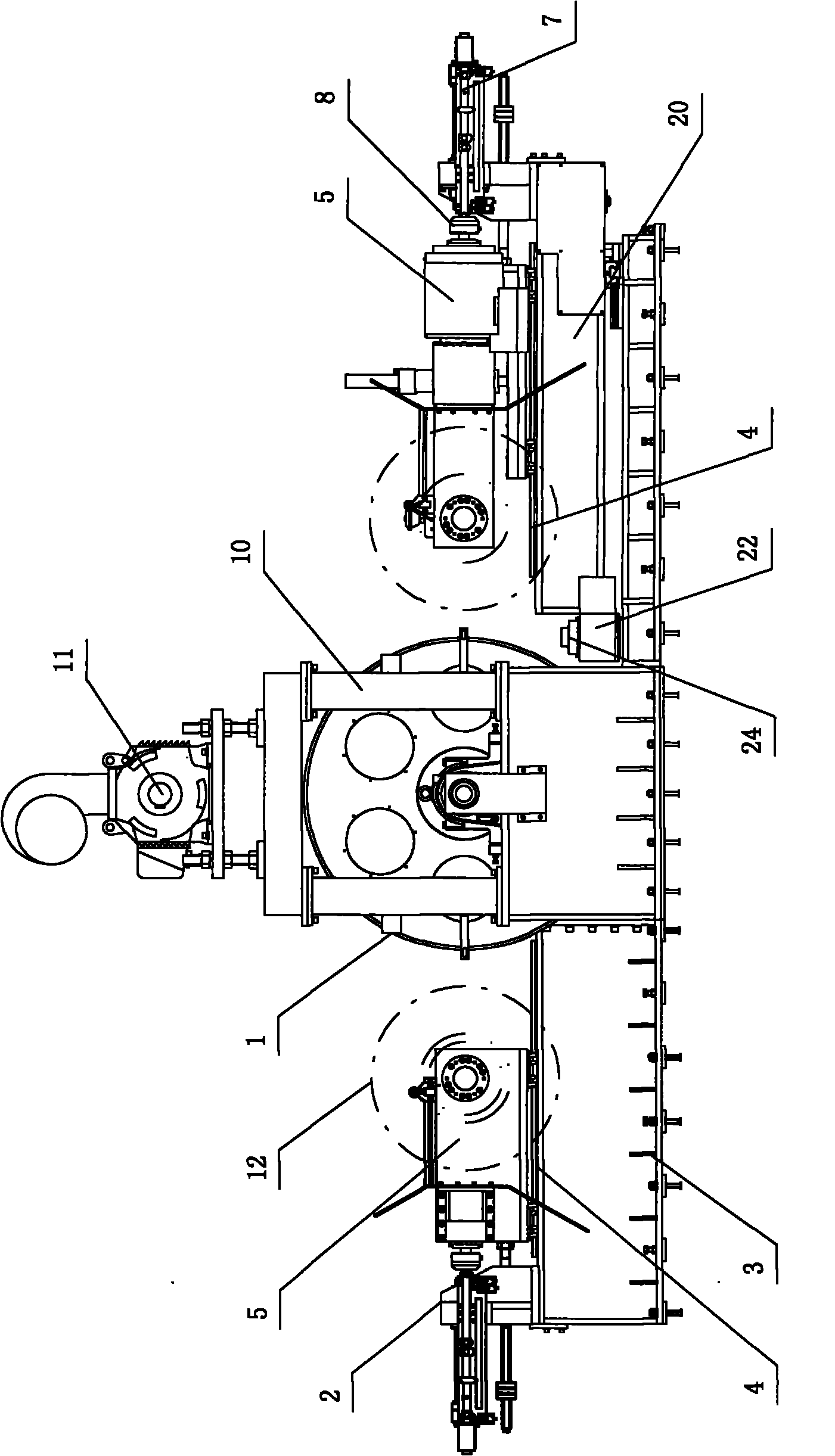

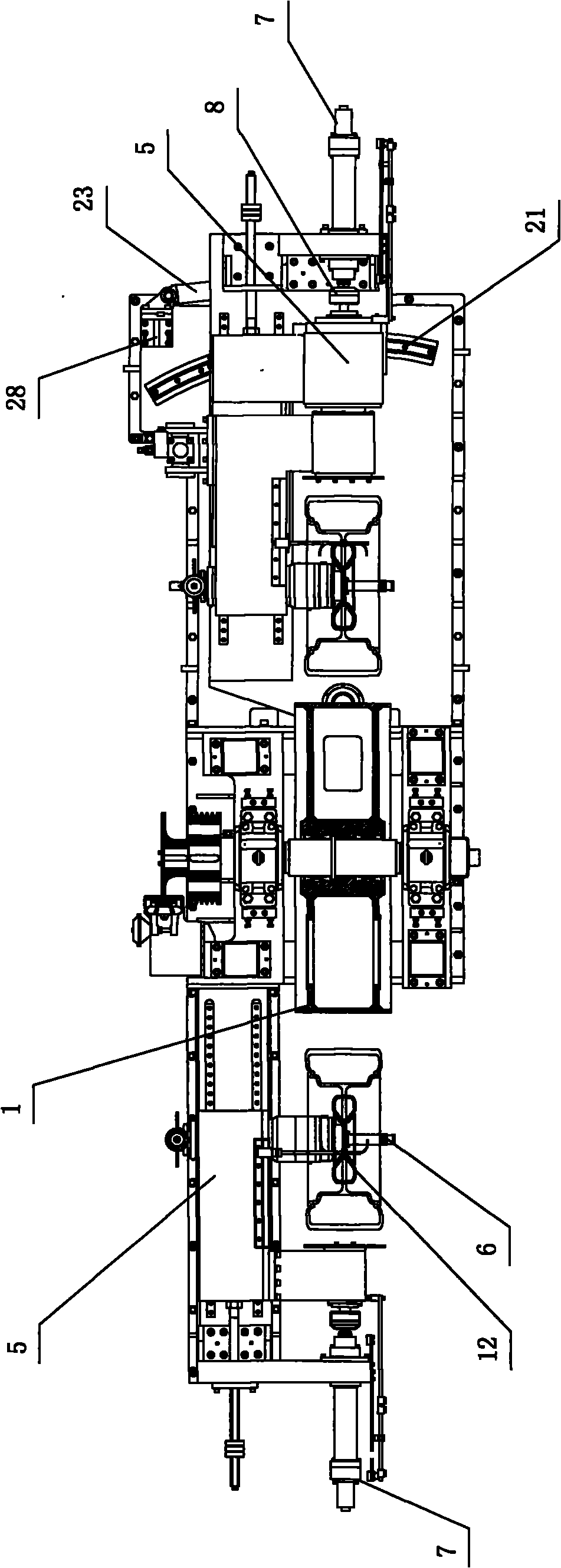

[0053] Example 1, such as Figure 1 to Figure 6 As shown, the tire durability inclination detection device is applied to tire high-speed / durability experiments, mainly including:

[0054] One rack 10;

[0055] On the frame 10, a drum 1 driven by a motor 11 to rotate on a fixed axis to simulate a driving road surface is arranged;

[0056] The stations on both sides of the drum 1 are respectively provided with a tire basic loading and power system composed of a hydraulic pressure device 2 and a moving seat 5 .

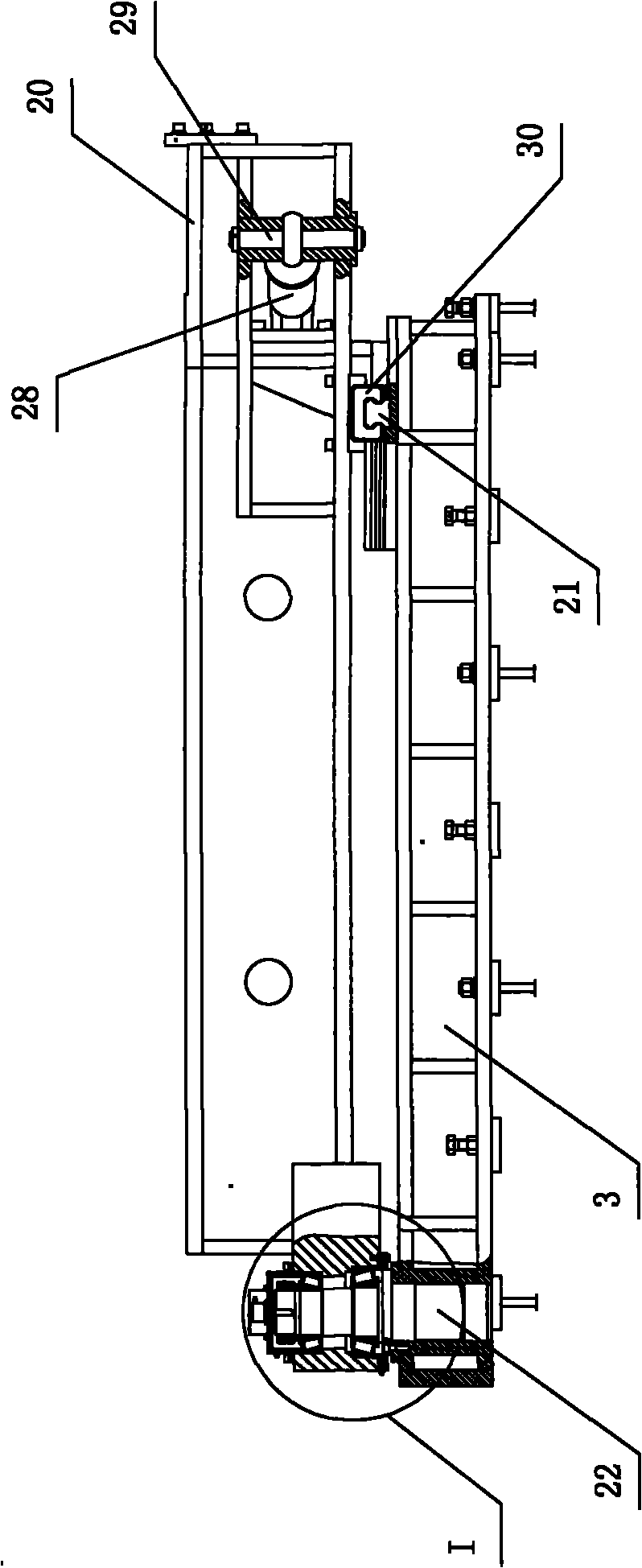

[0057] The hydraulic pressure device 2 is provided with a base 3, and the moving seat 5 is carried on the swing base 20 through the linear slide rail 4 provided at the bottom thereof;

[0058] The front end of the moving seat 5 is provided with a rim fixing shaft 6 for fixedly installing the detected tire 12; the rear end of the moving seat 5 is connected to a hydraulic pressure force provided by a load cell 8 to press the detected tire 12 on the surface of the drum 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com