Visual inspection method and system for intelligent substation

A technology of smart substations and inspection systems, applied in the field of smart substations, can solve the problems of insufficient accuracy of inspection results and insufficient inspection efficiency, achieve a wide range of reports, improve accuracy and reliability, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

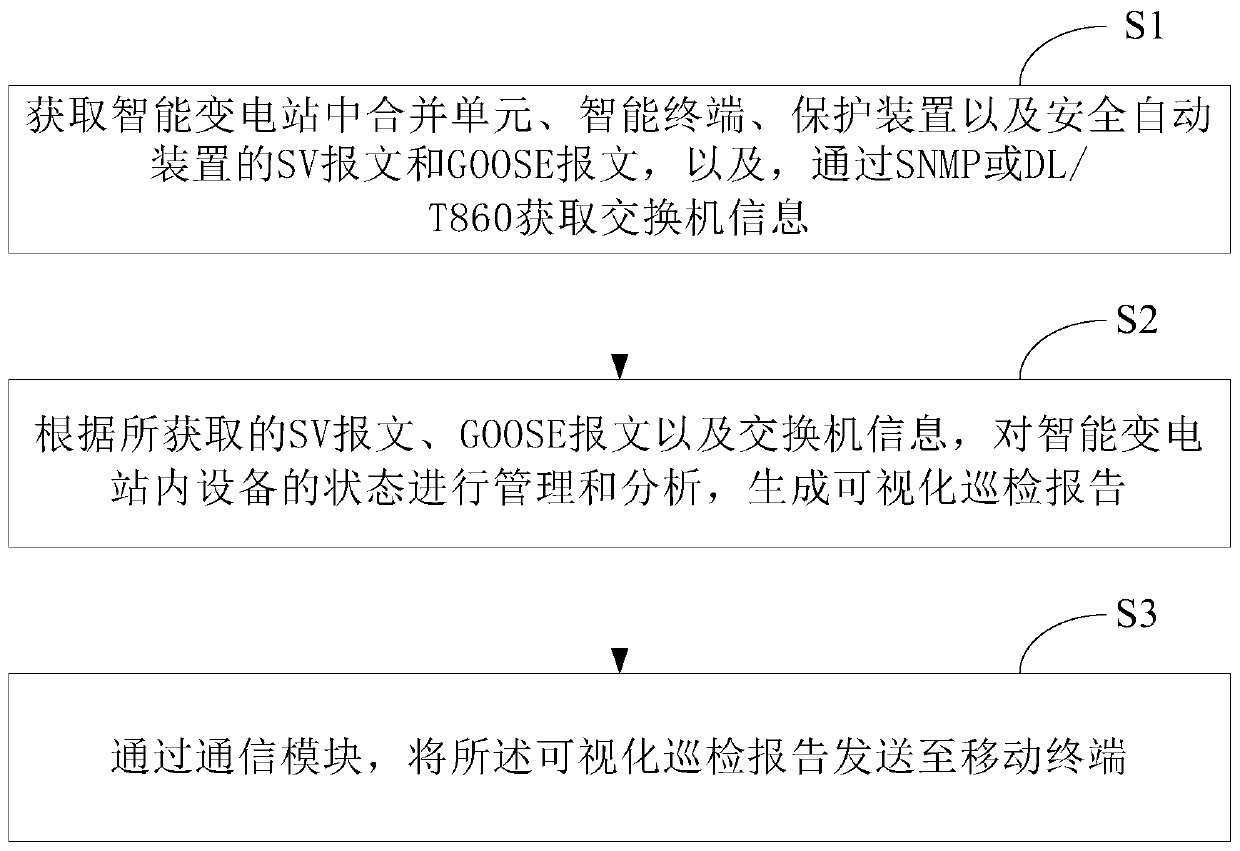

[0060] see figure 1 , figure 1 It is a schematic flowchart of a visual inspection method for a smart substation provided in the embodiment of the present application. Depend on figure 1 It can be seen that the visual inspection method for smart substations in this embodiment mainly includes the following processes:

[0061] S1: Obtain the SV message and GOOSE message of the merging unit, intelligent terminal, protection device, and safety automatic device in the smart substation, and obtain switch information through SNMP or DL / T860.

[0062] Among them, the merging unit and the intelligent terminal are set in the process layer of the smart substation, and the protection device and the safety automatic device are set in the station control layer of the smart substation. The SV message and GOOSE message data come from the process layer of the smart substation, and the fixed value and soft pressure plate check data come from the interval layer and station control layer.

[0...

Embodiment 2

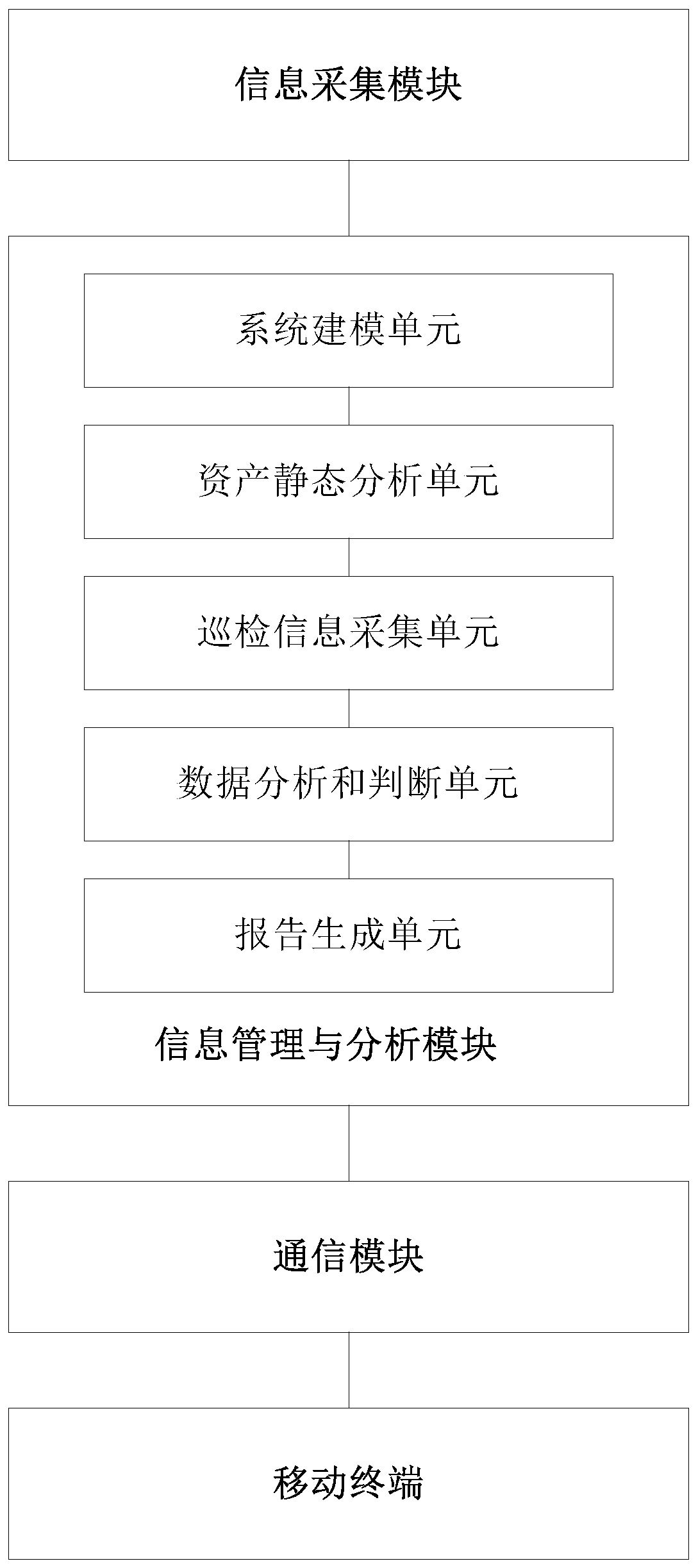

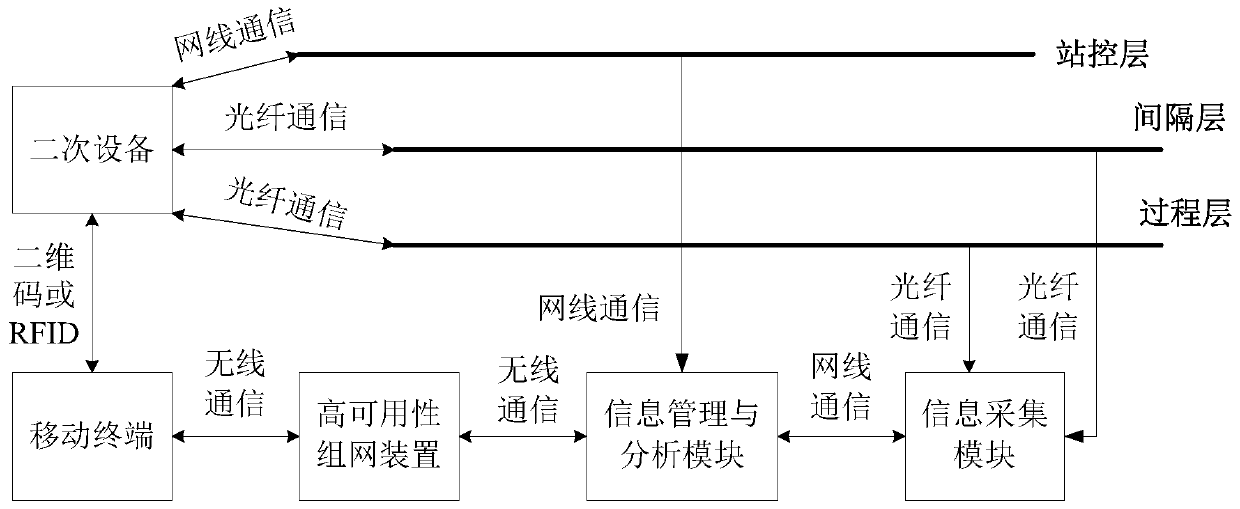

[0103] see figure 2 , figure 2 It is a schematic structural diagram of a visual inspection system for a smart substation provided by an embodiment of the present application. Depend on figure 2 It can be seen that the visual inspection system of the smart substation in this embodiment mainly includes four parts: an information collection module, an information management and analysis module, a communication module and a mobile terminal.

[0104] Among them, the information collection module is used to obtain the SV message and GOOSE message of the merging unit, intelligent terminal, protection device and safety automatic device in the smart substation, and obtain the switch information through SNMP or DL / T860, wherein the merging unit and The intelligent terminal is set in the process layer of the smart substation, and the protection device and safety automatic device are set in the compartment layer of the smart substation. The information management and analysis module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com