Hammer and method for tracking motion of hammer head

A technology of hammer head and forging hammer, which is applied in the field of forging hammer and hammer head used to track the movement of forging hammer, which can solve the problems of workpiece thickness reduction and achieve the effects of accurate measurement, less vibration and less thermal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

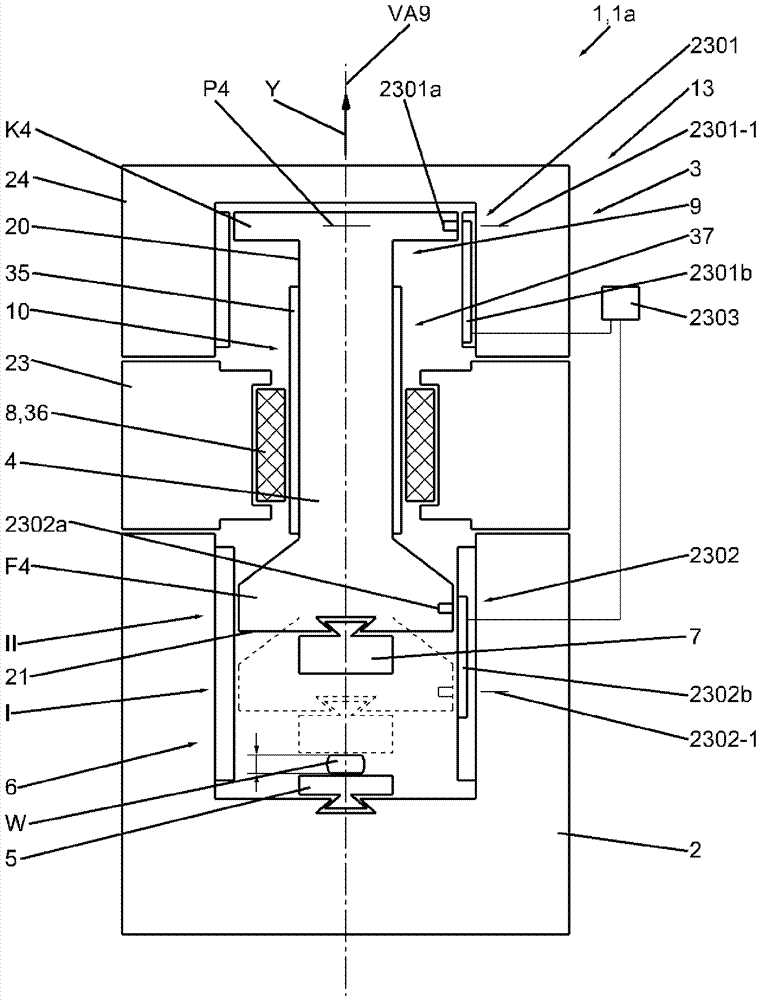

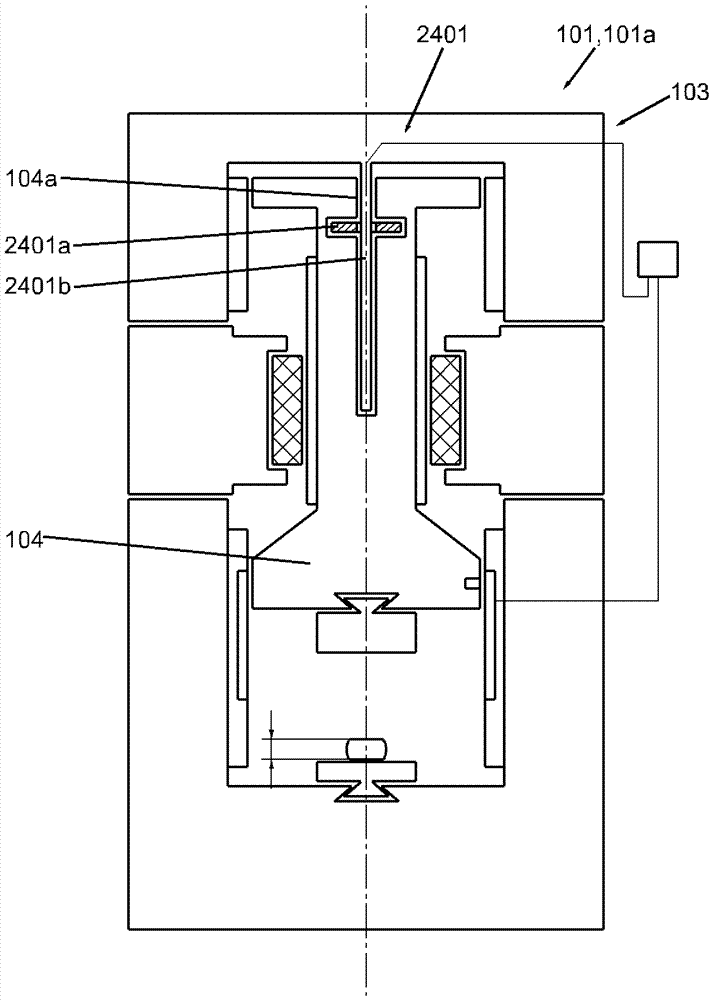

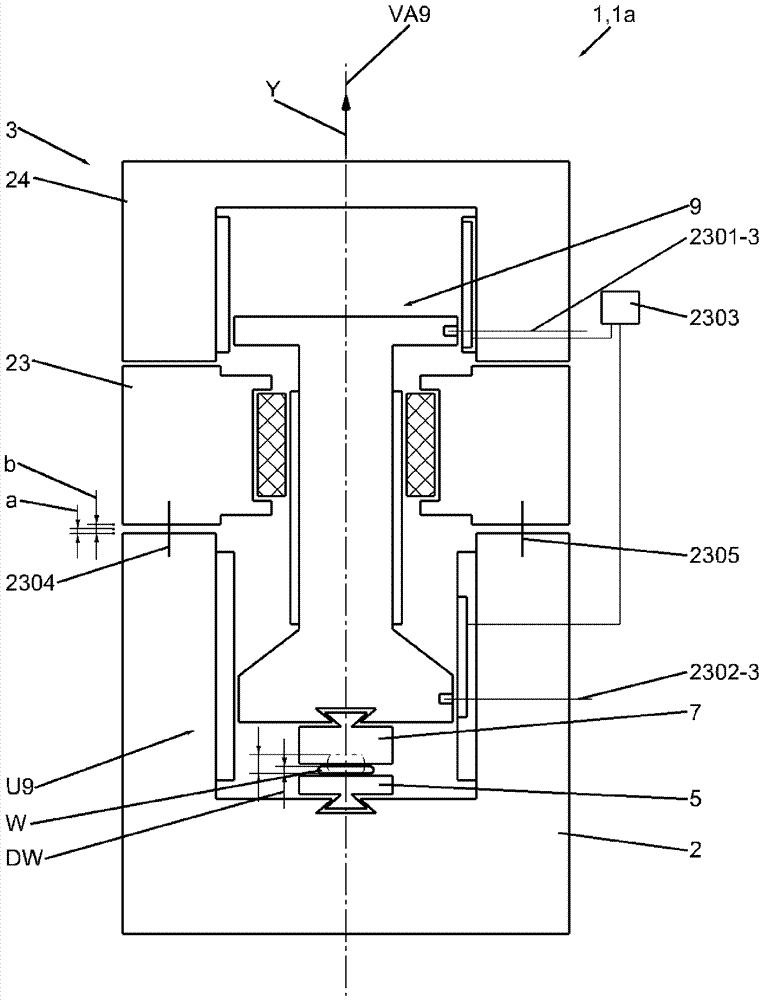

[0075] exist figure 1 A schematic diagram shows a forging hammer 1 configured as a linear hammer 1a. The linear hammer 1 a includes a frame 13 and a rotor 9 . The rotor 9 comprises a striker 4 and a secondary part 35 which is connected in a non-displaceable manner to the lateral surface 20 of the striker 4 in the direction of the travel axis VA9 of the rotor 9 . for Figures 1 to 3 For clarity of illustration, not all cutaway components are shown.

[0076] The frame 13 includes an anvil 2 and a head part 3 connected to the anvil 2 . For the complete construction of the linear motor 10 , the linear hammer 1 a includes a stator 8 with a primary part 36 . By means of the linear motor 10, the rotor 9 can be moved from the lower position I indicated by the dashed line along the travel axis VA9 of the rotor 9 to the figure 1 in the upper position II shown in and can be driven in reverse.

[0077] The stator 8 is connected to the head part 3 , wherein the head part 3 is designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com