Novel anti-deformation tie piece

A new anti-deformation technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of consuming welding time, wasting welding consumables, and difficulty in removing tension bars, so as to reduce the waste of welding consumables and save Effects on production cost, shortened installation and removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention, and should not limit the protection scope of the present invention with this.

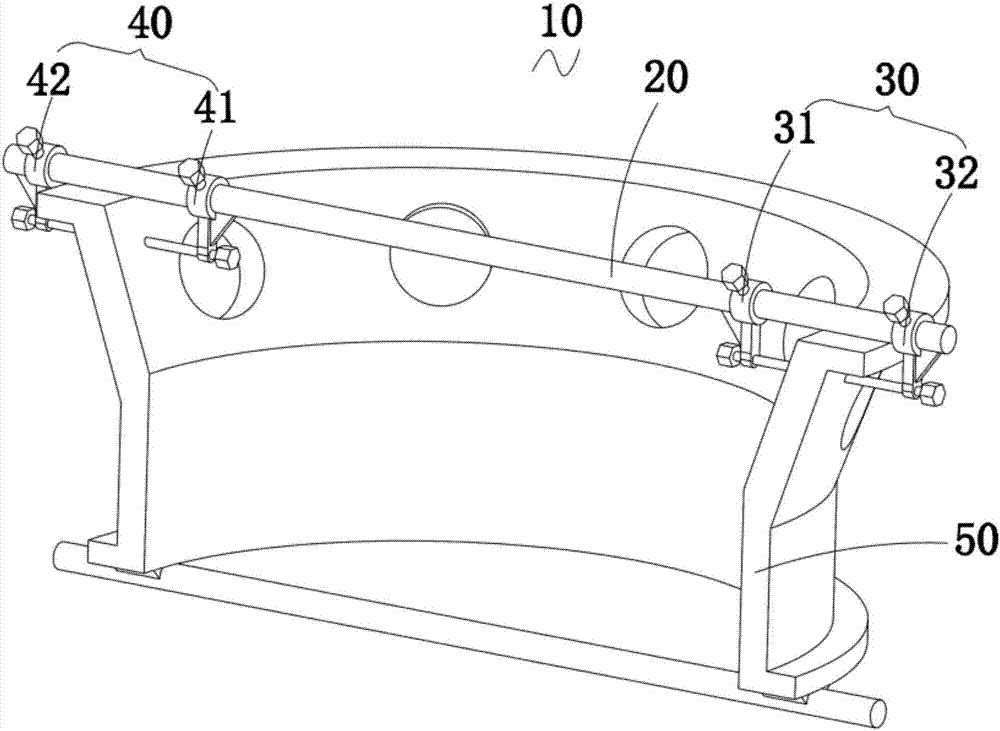

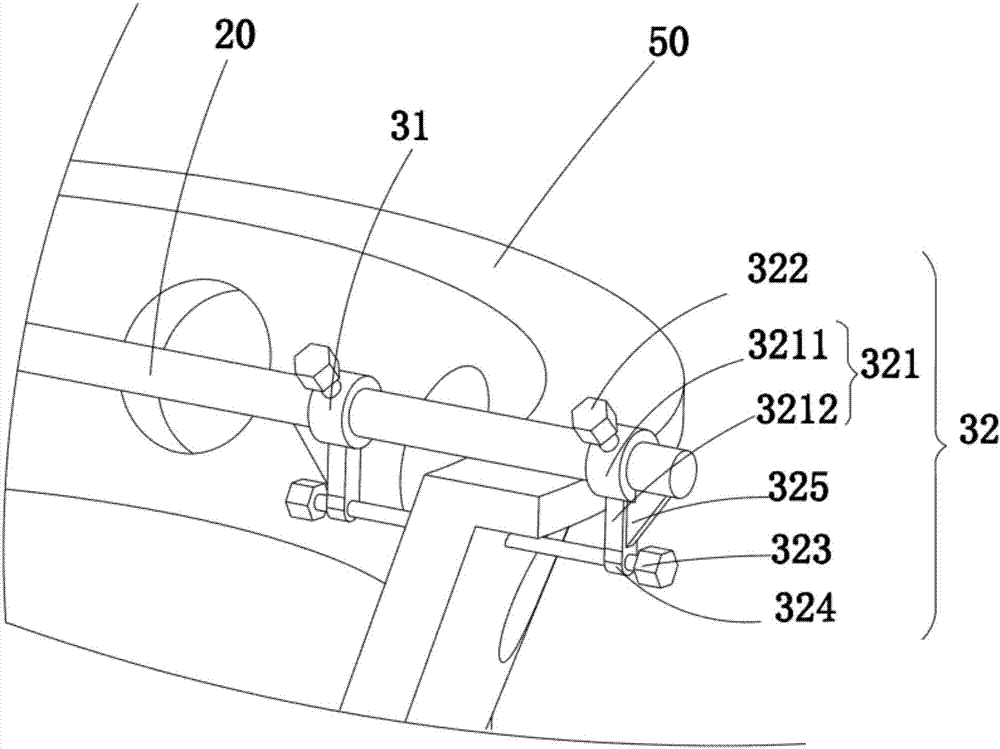

[0012] Please see figure 1 , figure 2 , the embodiment of the present invention provides a novel anti-deformation tie bar 10, comprising a tie bar 20, a first fixing card 30 and a second fixing card 40, the tie bar 20 is a long columnar metal body, the first fixing card 30 and the second fixing card The fixing cards 40 have the same structure and are arranged symmetrically at both ends of the tie bars 20. The first fixing card 30 includes a first inner card 31 and a first outer card 32, and the second fixing card 40 also includes a second inner card 41 and a second inner card. The outer card 42, the first inner card 31 and the first outer card 32 of the first fixed card 30 are rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com