A container loading system with pallet line external circulation

A container and external circulation technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of irregular shape of parabolic stacking, reduced loading volume ratio, inaccurate mechanism positioning, etc., so as to improve loading efficiency and extend the Long service life and stable stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

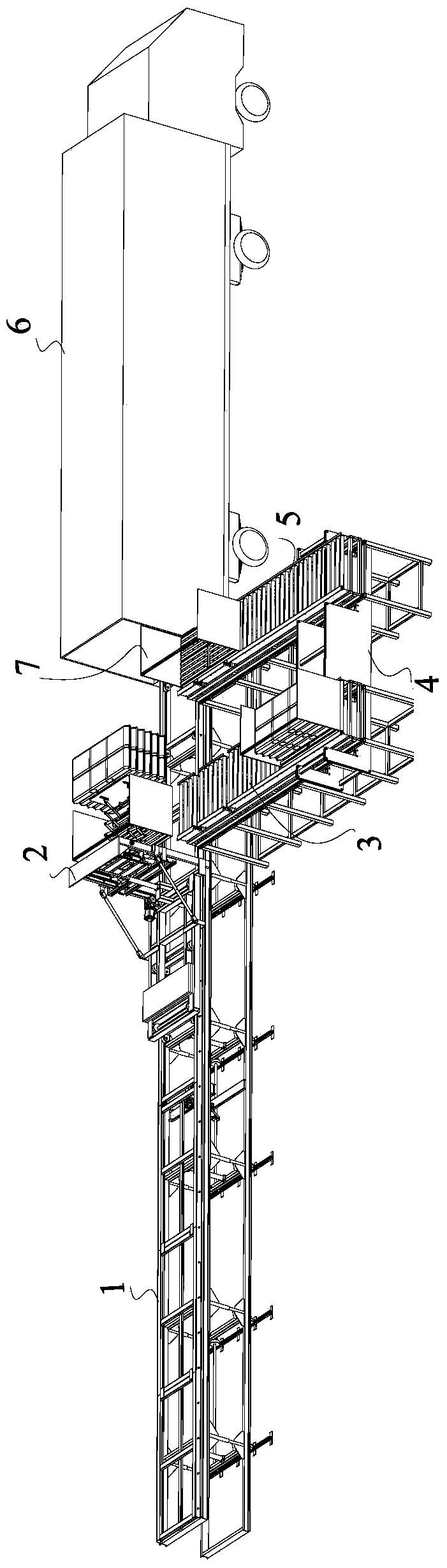

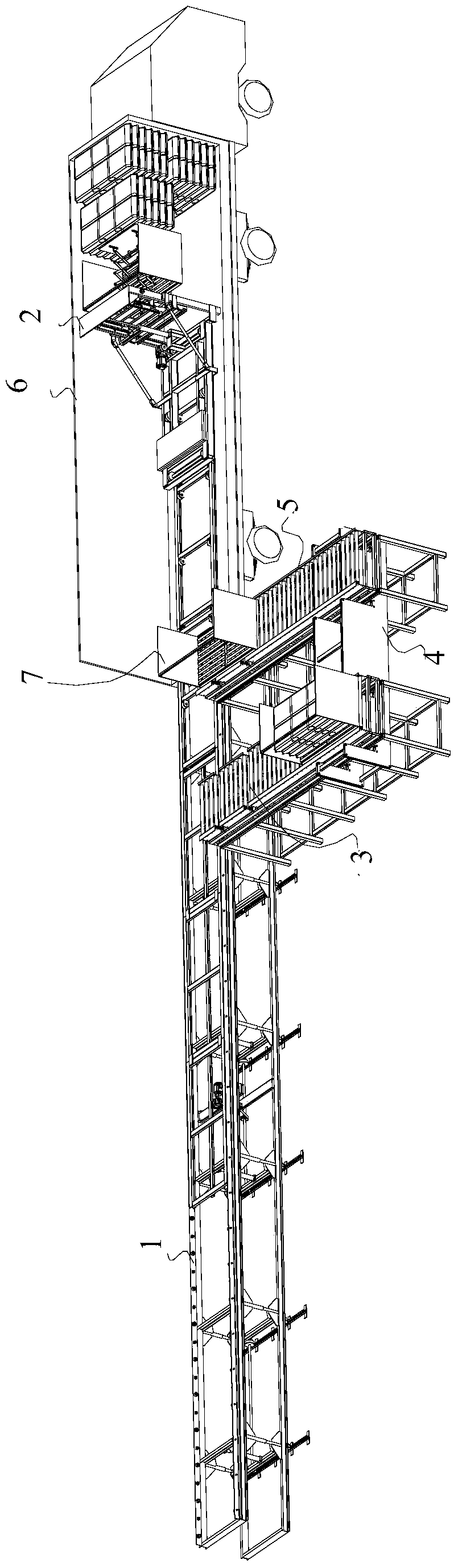

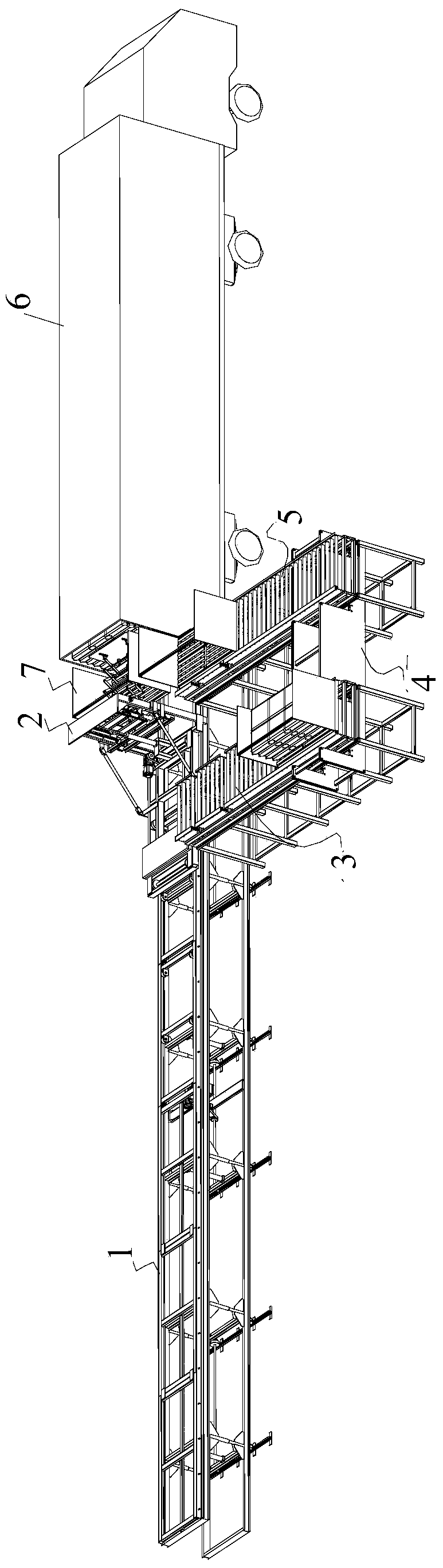

[0042] Such as figure 1 As shown in —3, a container loading system with pallet line external circulation includes automatic docking platform 1, articulated rail 8, multifunctional trolley 2, pallet driving into drum machine 3, pallet driving out of drum machine 5 and pallet span wire transplanter 4,

[0043] The automatic docking platform 1 is an automatic docking platform 1 that can be lifted up and down and moved left and right, which can ensure the precise positioning between the multifunctional trolley 2 on the hinged track 8 and the container;

[0044] The hinged track 8 is slidably installed on the upper end of the automatic docking platform 1, and is formed by connecting a rigid track and a telescopic track, such as Figure 4 Shown is a top view of the hinged track 8. The bottom of the telescopic track is provided with auxiliary supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com