Certificate making machine

A certificate and certificate paper technology, applied in the field of certificate production, can solve the problems of low efficiency, difficulty in realizing automatic equipment, easy leakage of information by manual operation, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

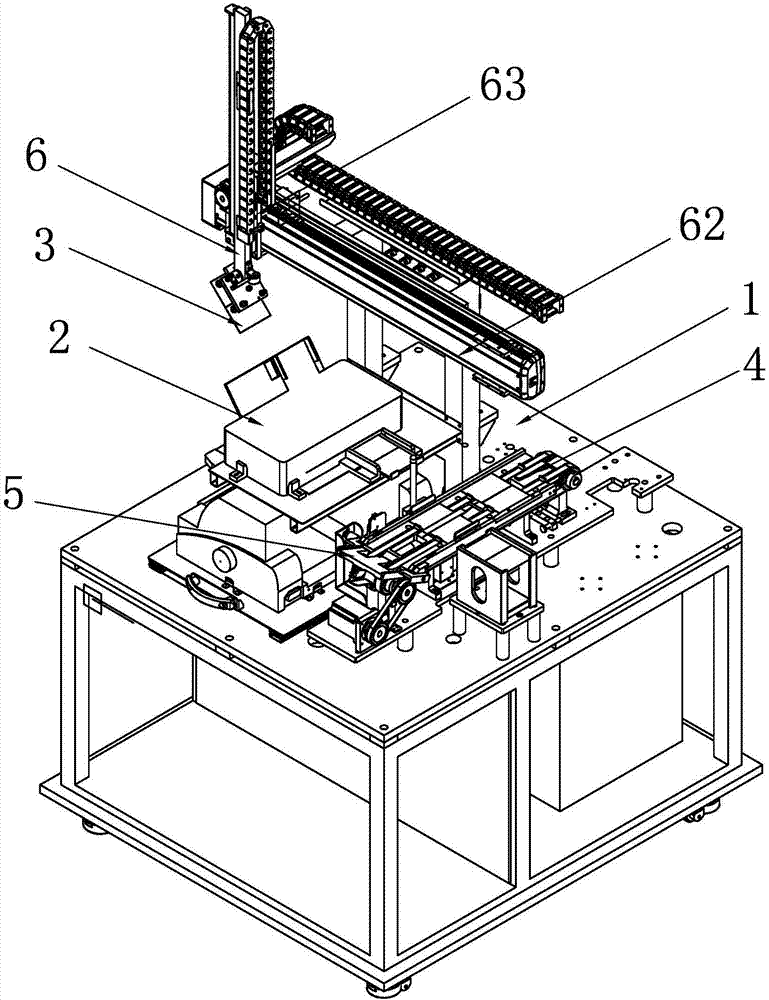

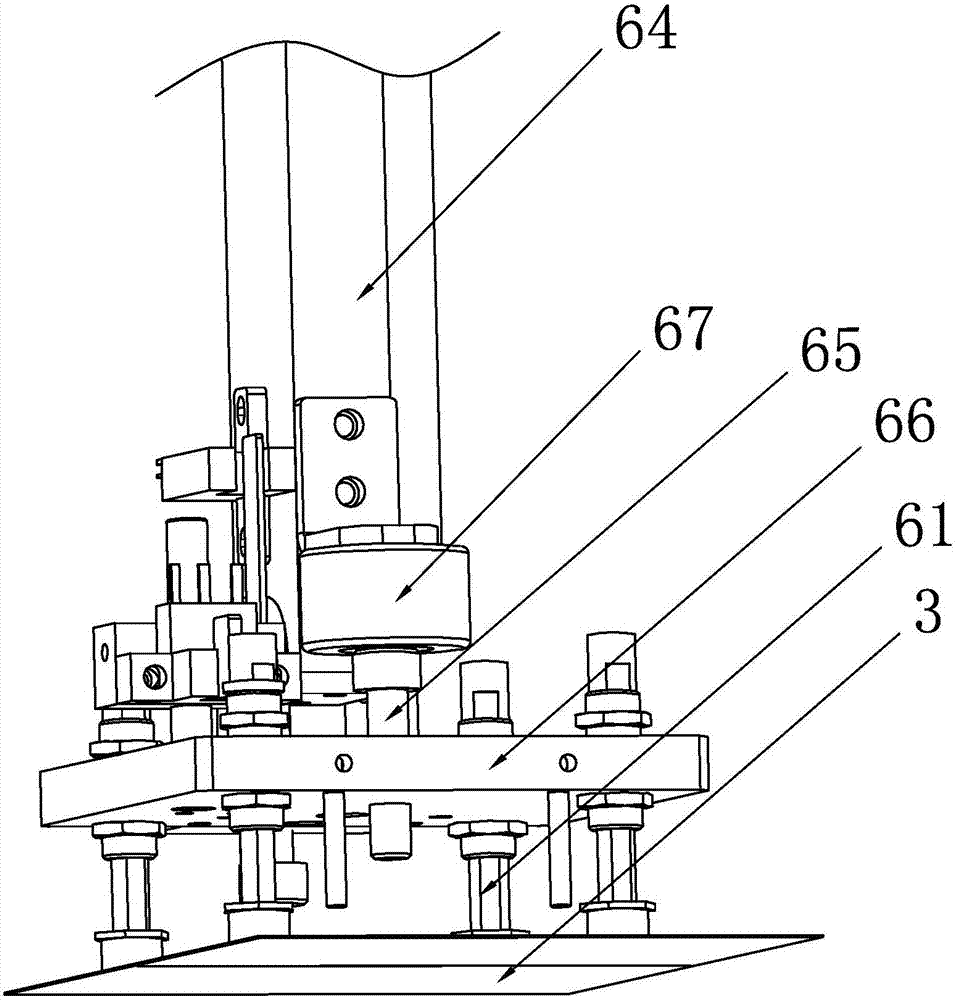

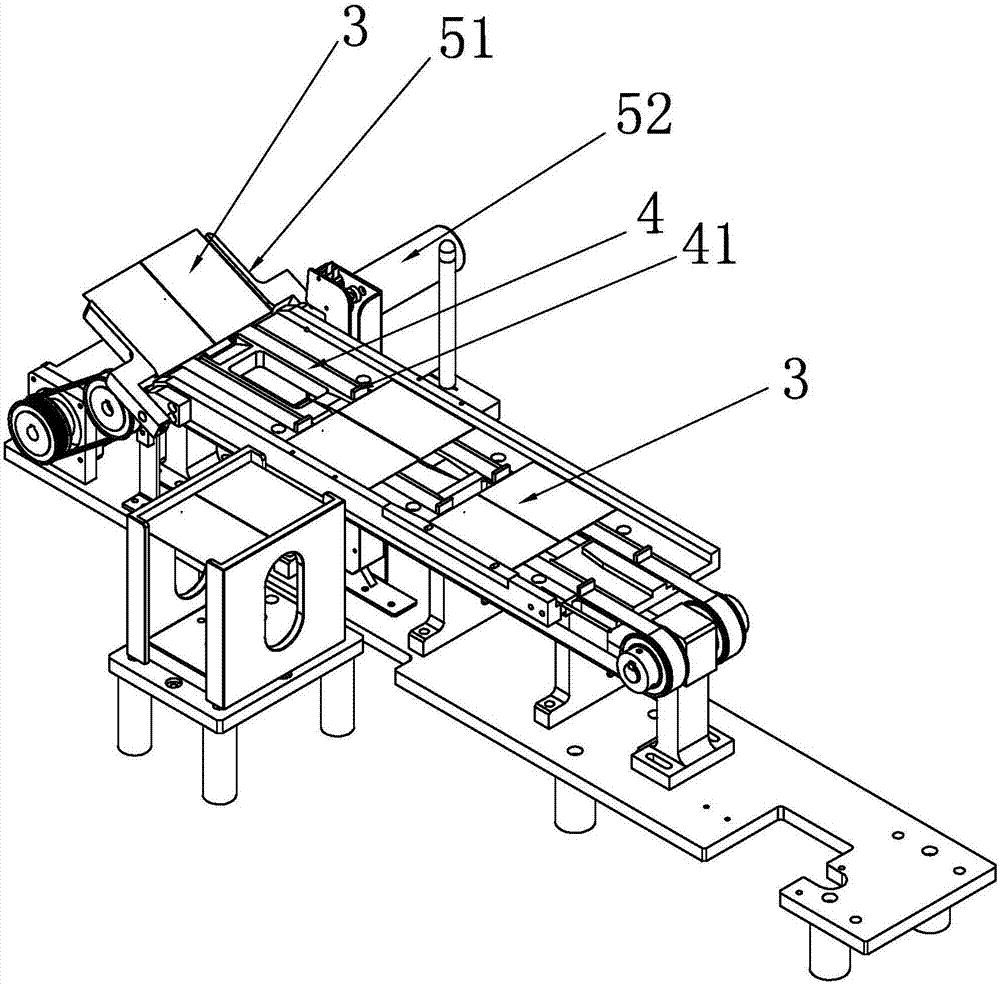

[0022] This embodiment is a driver's license making machine, and the purpose is to make the certificate paper into a driver's license sub-page and a driver's license front page with a protective film. Other types of certificates are also applicable to the present invention, see figure 1 , image 3 , Figure 5 and Figure 7 , a certificate making machine of the present invention, comprising a frame 1, a printer 2, a conveyor belt 4, a turning mechanism 5, a pick-and-place mechanism 6, an assembly mechanism 7 and a cutting mechanism 8, and the printer 2 is installed on the frame 1 , divided into a color printer and a dot matrix printer. The two printers 2 are used for color printing and dot matrix printing on the credential paper 3 respectively. The conveyor belt 4 can transport the credential paper 3 forward or reverse. Stretch out and be provided with the stopper 41 that is limited to certificate paper 3.

[0023] see further image 3 and Figure 4 The turnover mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com