Subsea pipeline installation servo robot

A technology for submarine pipelines and robots, applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems of difficult to guarantee detection accuracy, low detection efficiency, and high work risk for detection personnel, and achieve the effect of reliable applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

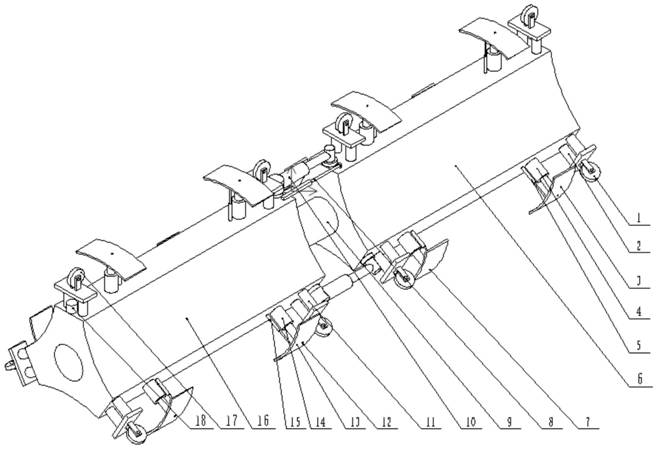

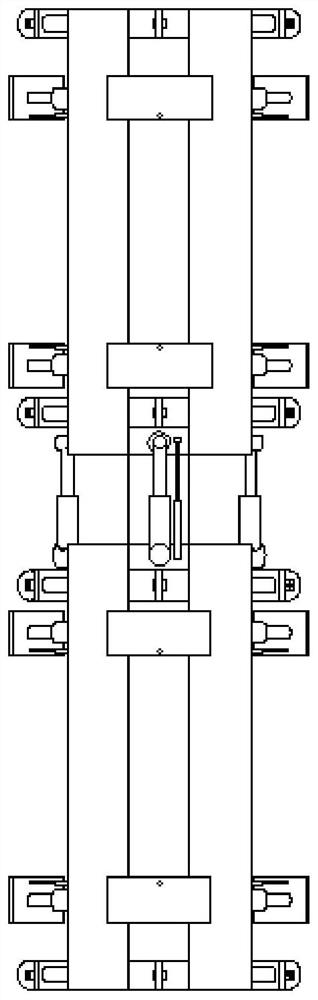

[0014] see Figures 1 to 2 , The subsea pipeline installation servo robot of this embodiment includes an insertion mechanism, a socket mechanism, a feeding mechanism, and a monitoring system. The insertion mechanism includes an insertion roller 1, an insertion lifting screw 2, an insertion rubber plate 3, an insertion hydraulic cylinder 4, and an insertion mechanism. Main body 6; the socket mechanism includes a socket lifting screw 11, a socket rubber plate 13, a socket hydraulic cylinder 14, a socket main body 16, and a socket roller 17; the feeding mechanism includes a support rod 9 and a feeding hydraulic cylinder 10; monitoring The system includes an insertion position sensor 5 , an insertion force sensor 7 , a feeding position sensor 8 , a socket force sensor 12 , a socket position sensor 15 , and a camera 18 . The socket body 16 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com