Chamber temperature monitoring method

A chamber, actual temperature technology, used in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as monitoring epitaxy chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

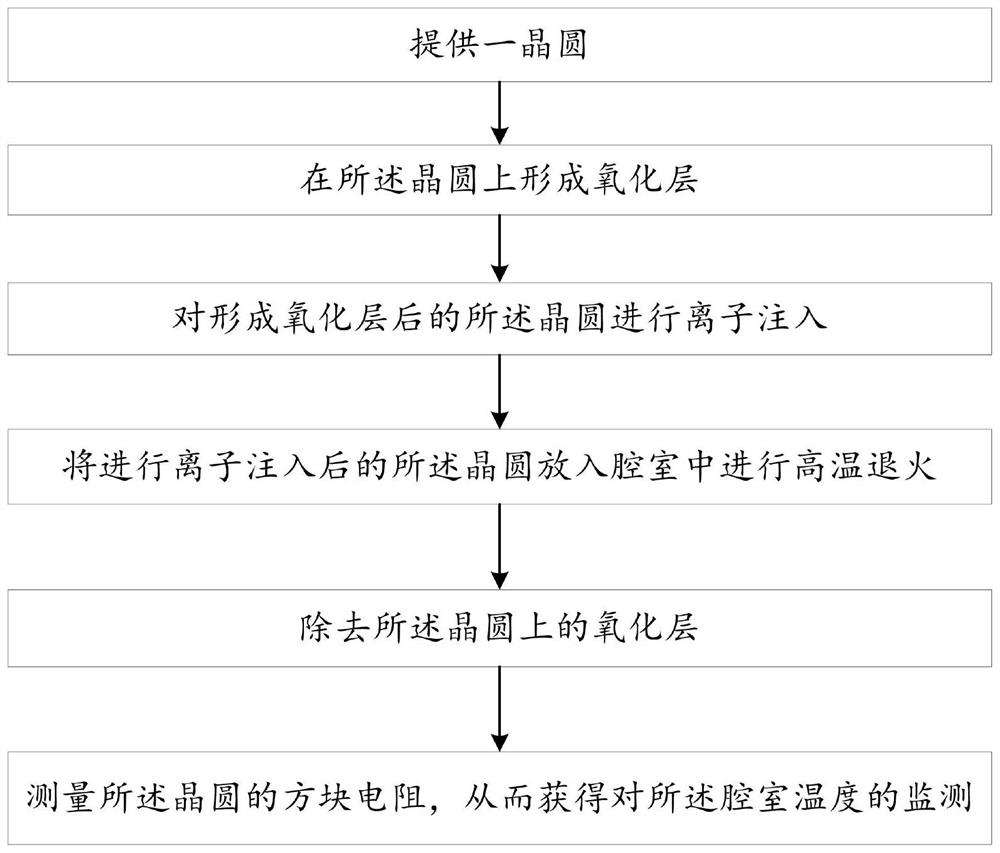

Method used

Image

Examples

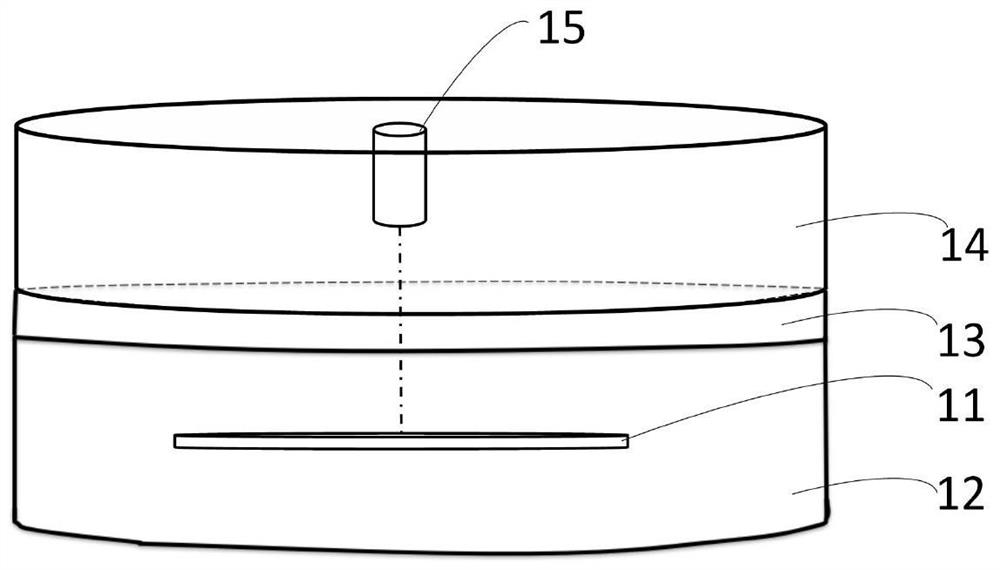

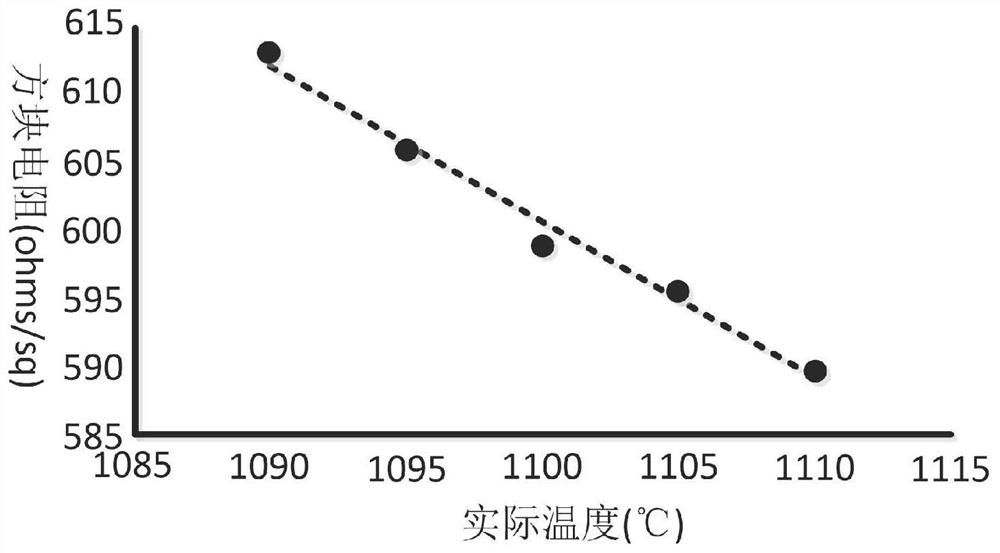

Embodiment Construction

[0035] At present, in the atmospheric pressure epitaxy process, the process temperature is a very important parameter, and the process temperature corresponds to the temperature of the chamber of the epitaxy machine, so the accuracy of monitoring the temperature of the chamber of the epitaxy machine is of great significance. The main factors affecting the accuracy of the chamber temperature are: ① Whether the pyrometer itself is normal; ② The influence of the cover plate. As for the influence of the cover plate, at present, the only way to judge whether there is residual coating on the cover plate is through regular cavity opening, and observers can observe with naked eyes. However, this method of observing with the naked eye is not reliable, and there are also large differences between different observers. Therefore, the deviation between the reading temperature of the pyrometer and the actual temperature of the chamber caused by the influence of the cover plate cannot be disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com