Process equipment for improving power capability of steam turbine of waste heat power generator set

A technology for generating sets and process equipment, which is applied to steam generating devices, lighting and heating equipment, and steam superheating, etc. The effect of improving working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

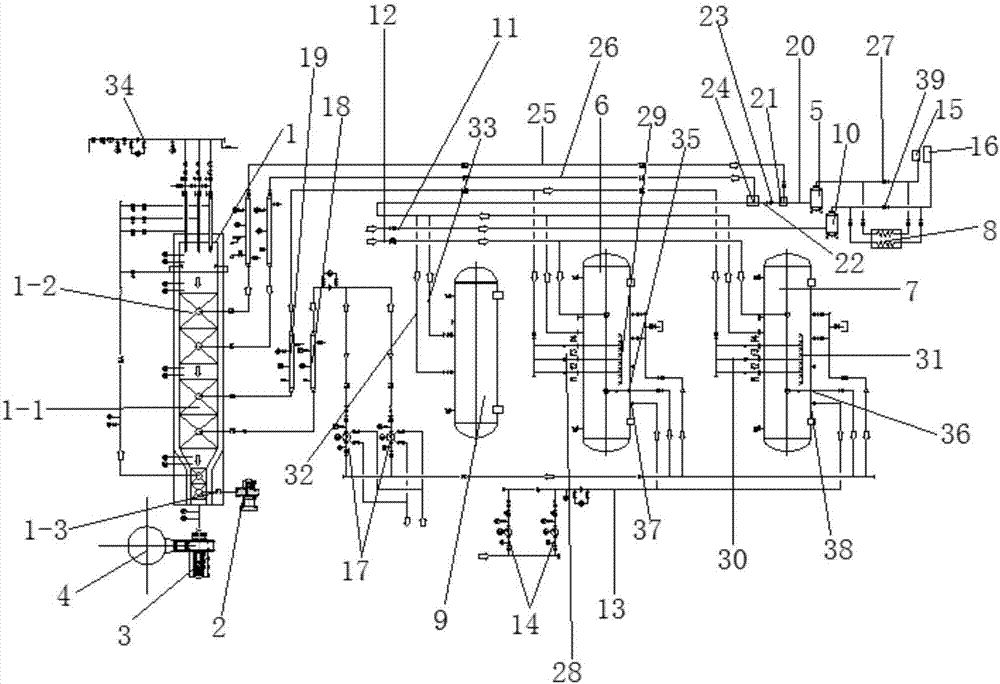

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] The present invention is used to improve the process equipment of the steam turbine of the waste heat generating set, and the structure is as follows figure 1 As shown, it includes a gas supplementary combustion device 1, one end of the gas supplementary combustion device 1 is connected to a gas source pipeline 34, and the other end of the gas supplementary combustion device 1 is respectively connected to a combustion-supporting fan 2 and an induced draft fan 3, and the induced draft fan 3 is connected to a chimney 4 The gas supplementary combustion device 1 is respectively connected with the main steam-steam water separator 5, the main steam accumulator I6 and the main steam accumulator II7, and the main steam-steam water separator 5 is also respectively connected with a steam-steam heat exchanger 8 and a supplementary steam accumulato...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap