Compressed air heat-linkage energy-storage system based on reversible air engine

An air engine and compressed air technology, which is applied in the direction of non-variable engines, engine components, machines/engines, etc., can solve the problems of taking away large energy, reducing engine efficiency, and high residual pressure at the end of expansion, so as to improve the working ability , reduce energy loss, and quickly change working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

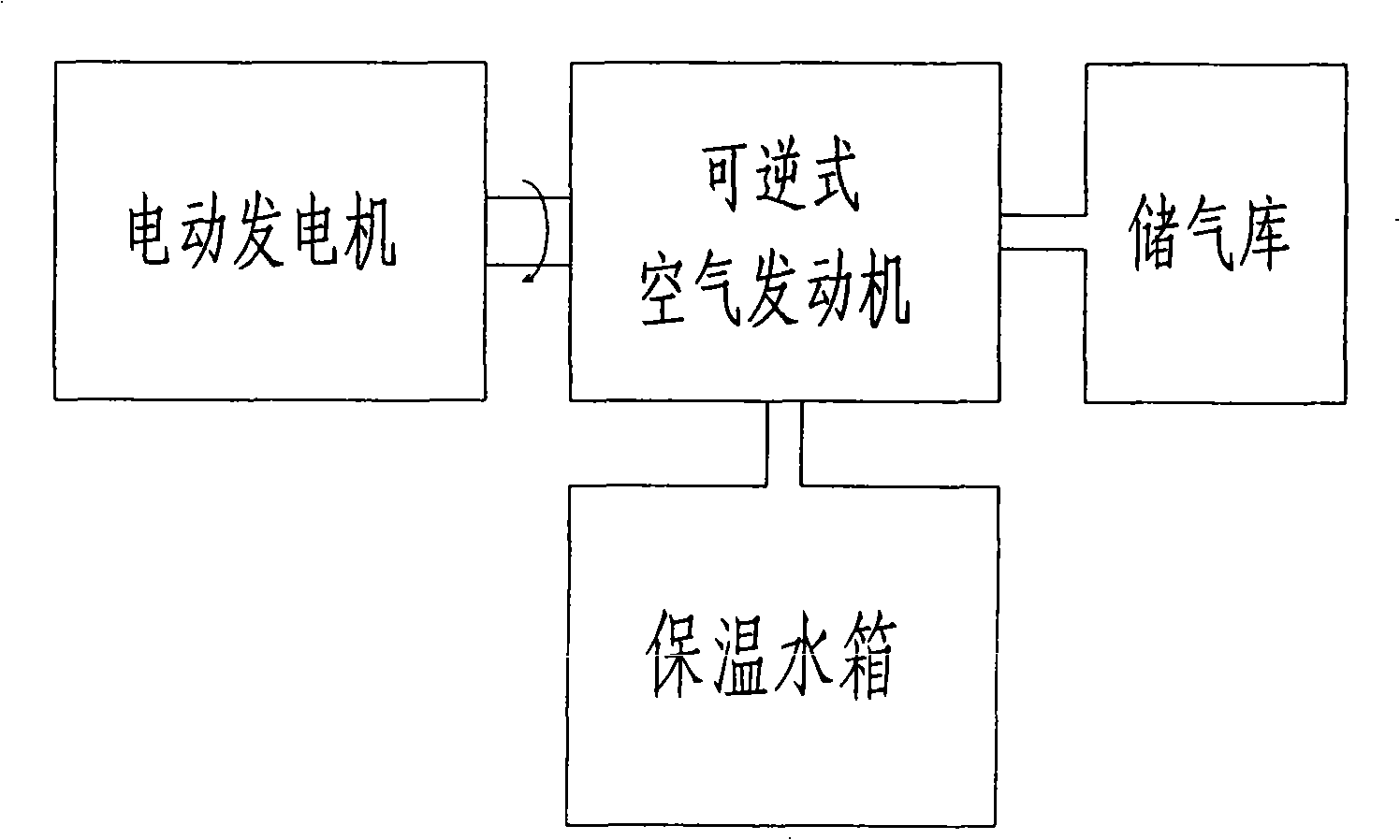

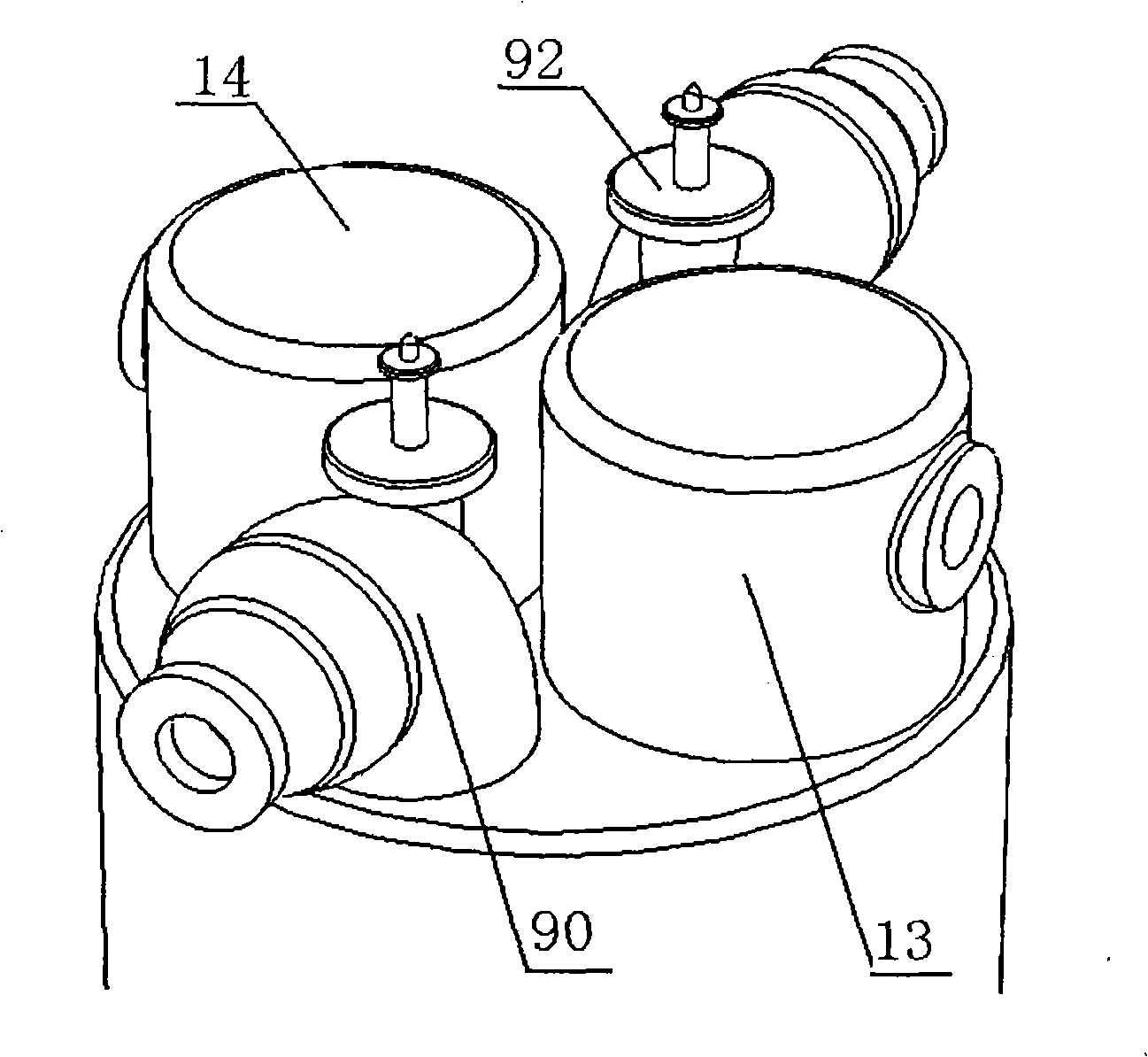

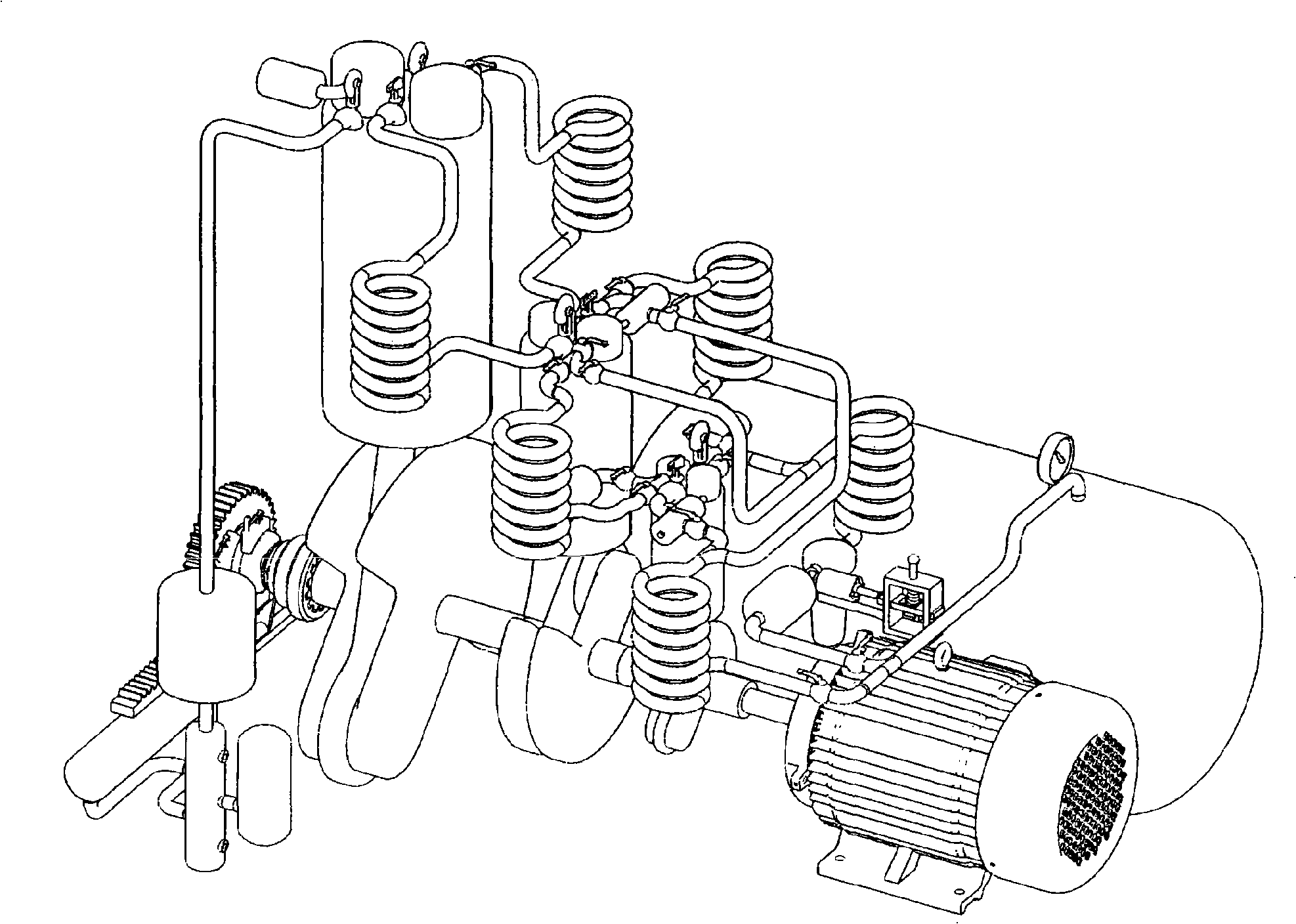

[0044] Such as figure 1 - As shown in FIG. 8 , the overall structure of the present invention includes four parts: a motor generator 1 , a reversible air engine, an air storage 24 and an insulated water tank 23 . The motor generator 1 is connected to the reversible air engine through the speed reducer 2, the reversible air engine is connected to the gas storage 24 through pipelines, and the heat preservation water tank 23 is connected to the cooler, regenerator and water jacket of the reversible air engine; the gas storage 24 is provided with pressure gauge 25.

[0045] The motor generator 1 is a generator that doubles as a motor or a motor that doubles as a generator, or a squirrel cage induction motor or a synchronous motor, or a reversible motor generator in a pumped storage power station.

[0046] The gas storage 24 is a cave or a salt rock layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com