Lateral structure and arranging method of steam turbine generator unit of 1000MW-grade set in thermal power plant

A technology for steam turbine generator sets and thermal power plants, which is applied to steam engine installations, machines/engines, and mechanical equipment, etc., can solve the problems of long length of steam and water pipelines, high requirements for construction organization, and large engineering cost, and achieves simple construction organization, Reduce pressure drop and heat dissipation loss, improve the effect of working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

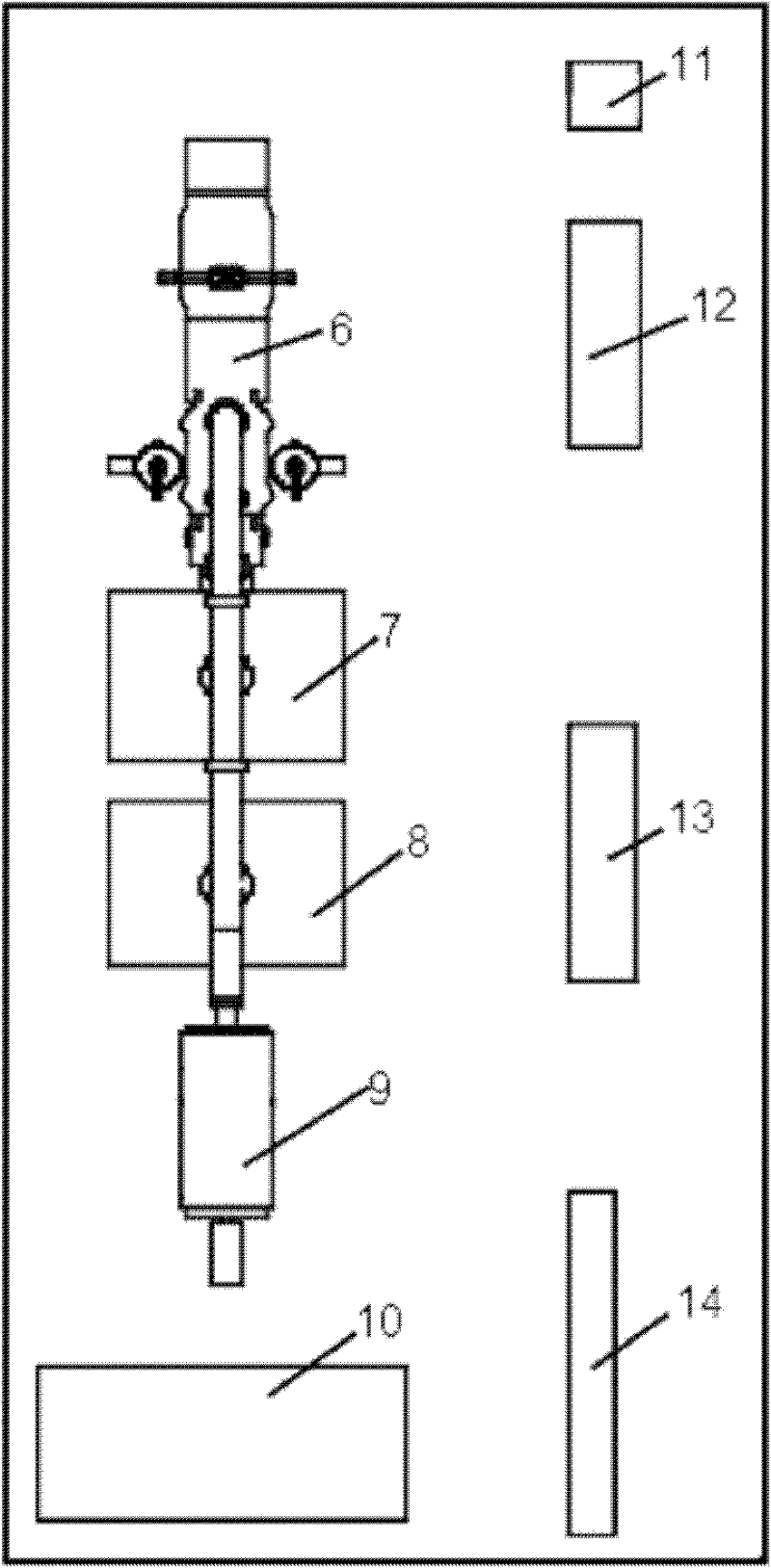

[0023] Such as figure 1 As shown, the main workshop adopts the layout scheme of turbine room and boiler room, and the 7m wide furnace front low seal is arranged between the turbine room and the boiler room. The coal bunker adopts the side coal bunker scheme and is arranged between the two boilers. The horizontal arrangement is adopted, the center line of the steam turbine generator set is aligned with the center line of the boiler room and the head of the steam turbine is arranged facing the boiler room, and the oxygen removal room is arranged on the left side of the steam turbine generator set (viewed from the direction of the head of the steam turbine). The site is set at the tail of the generator to facilitate the organization of construction, and a centralized control building is arranged between the two generators. The turbine room and the deaeration room are div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com