Injection/drainage air-supply turbocharging system

A technology of turbocharger system and turbocharger, which is applied in the direction of machine/engine, internal combustion piston engine, mechanical equipment, etc., can solve the problems of unstable work, limited promotion and application, consumption of large high-pressure air, etc., and saves money The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the technical content of the present invention will be further described through the embodiments and in conjunction with the accompanying drawings.

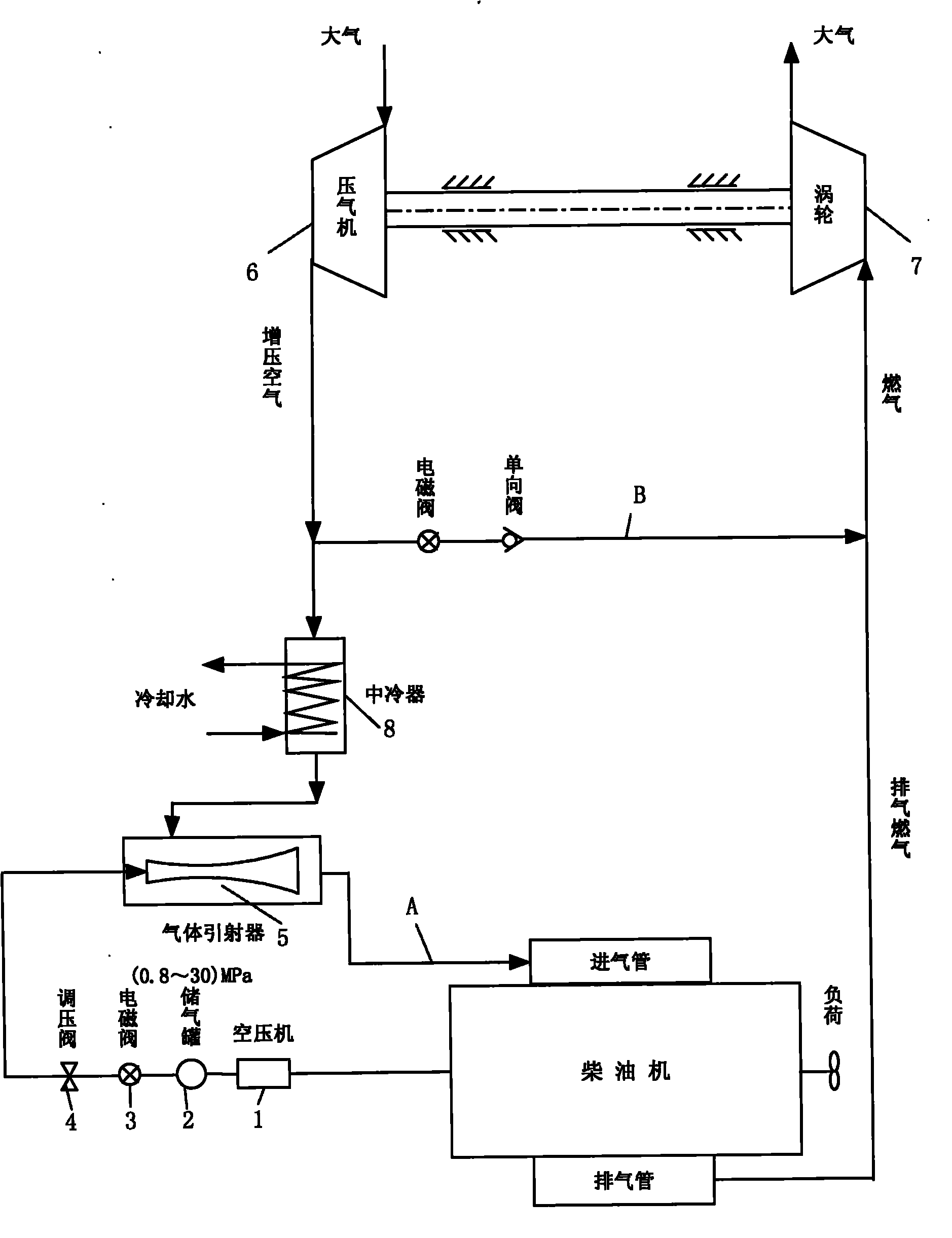

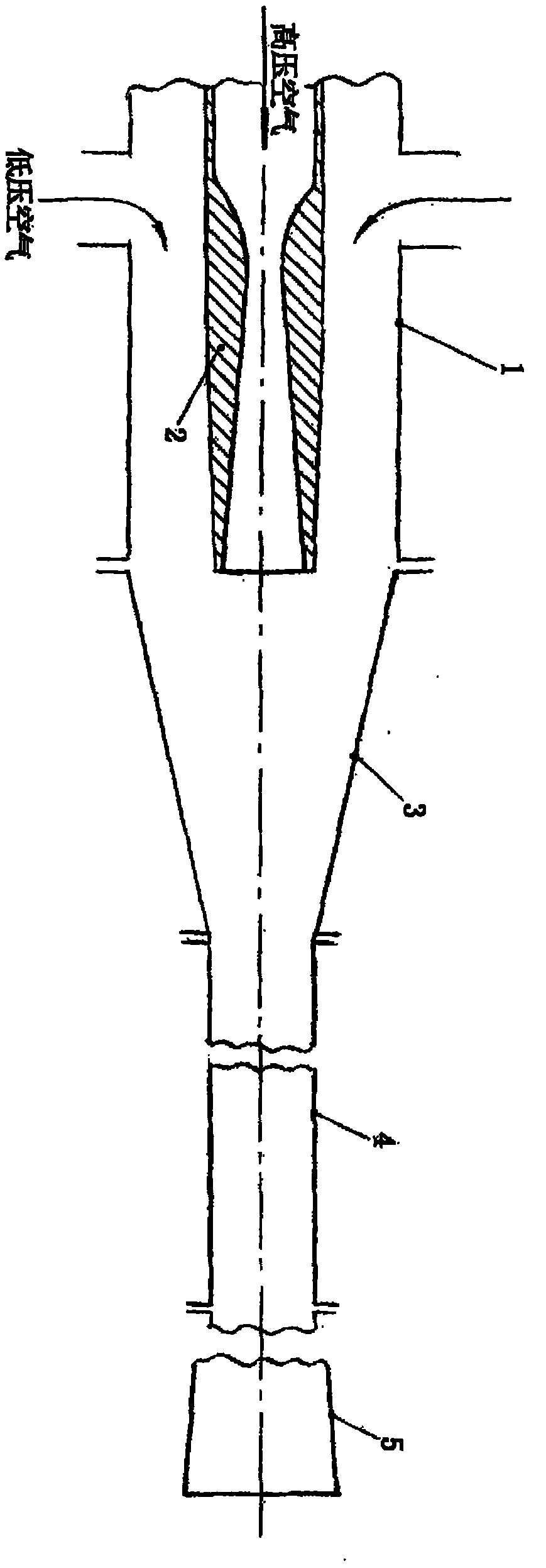

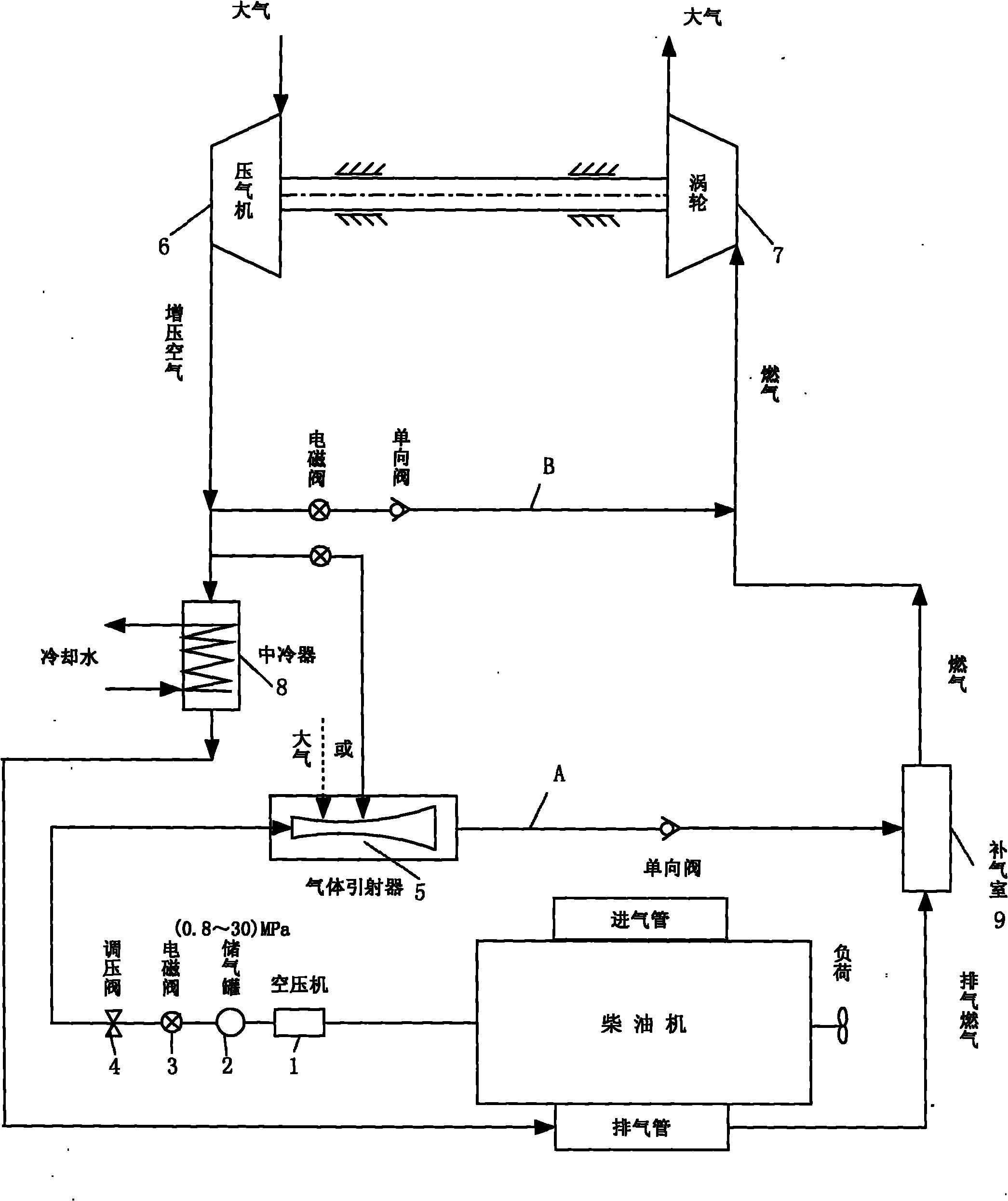

[0030] As mentioned above, the technical core of the present invention is to use the high-pressure compressed air flowing out from the air storage tank of the high-pressure compressed air supply device to accelerate the high-speed jet air formed by its expansion in the nozzle pipe of the gas injector to inject The low-pressure charge air that flows into the gas ejector cylinder from the outlet of the intercooler or the ambient air or the compressor outlet of the turbocharger is bypassed, and the two are mixed in the mixing section of the ejector and boosted through the diffuser tube Afterwards, "complement air" is formed, which is introduced into the intake pipe of the internal combustion engine and / or the guide tube installed in the box-shaped supplementary air chamber between the outlet flange of the exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com