Arc extinguishing device for molded case circuit breaker and molded case circuit breaker containing the same

A technology of molded case circuit breaker and arc extinguishing device, which is applied to circuit breaker parts, circuit breaker contacts, etc. and other problems, to achieve the effect of easy maintenance and replacement of parts, improvement of critical load current and short-circuit breaking capacity, and fast arc extinguishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

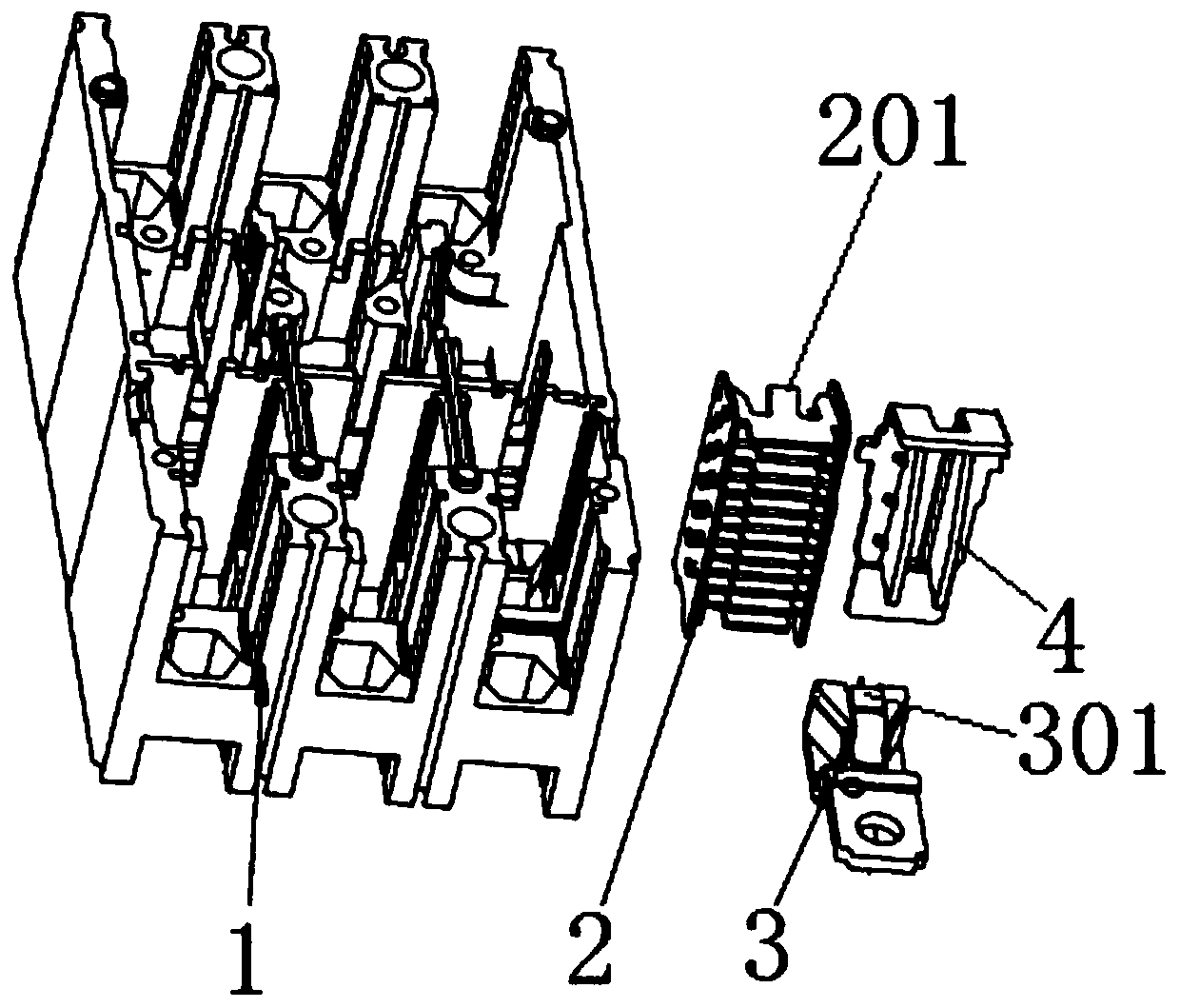

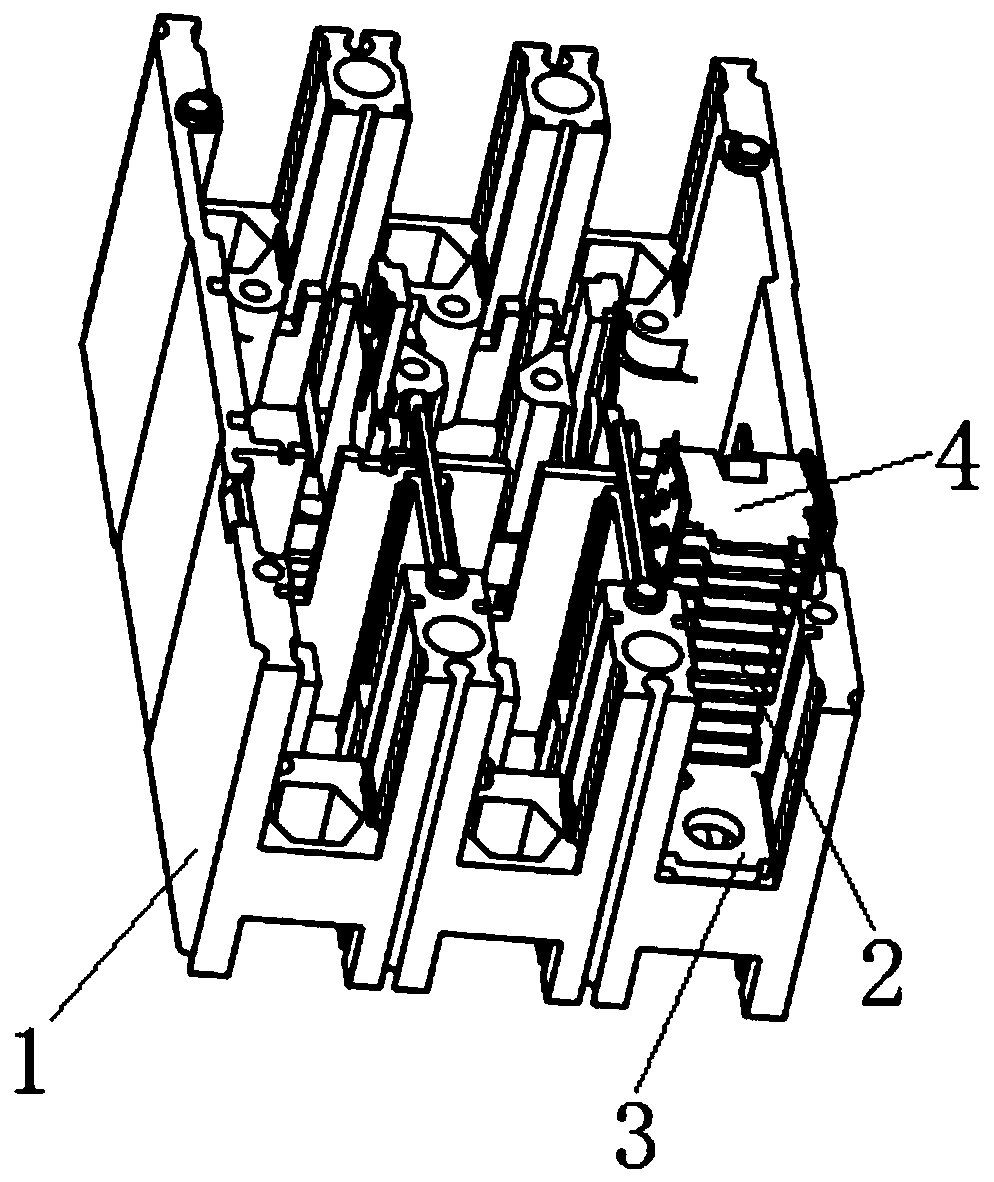

[0034] A molded case circuit breaker containing such as figure 1 , figure 2 The arc extinguishing device shown includes a base 1, a static contact 3 arranged on the base 1, an arc extinguishing chamber 2 arranged above the static contact 3, and an arc extinguishing chamber 2 adapted to The arc extinguishing cover 4, the arc extinguishing chamber 2 is provided with an arc extinguishing grid 201, and the static contact 3 is provided with a static contact 301 and an arc-igniting piece 5, the end of the arc-igniting piece 5 at the static contact 301 and The distance between the arc extinguishing grid pieces 201 is less than the distance between the end far from the static contact 301 and the arc extinguishing grid piece 201. The arc generated when the circuit is disconnected is introduced into the arc extinguishing chamber 2 by the arc extinguishing piece 5, and is guided The arc piece 5 and the arc extinguishing grid piece 201 are extinguished.

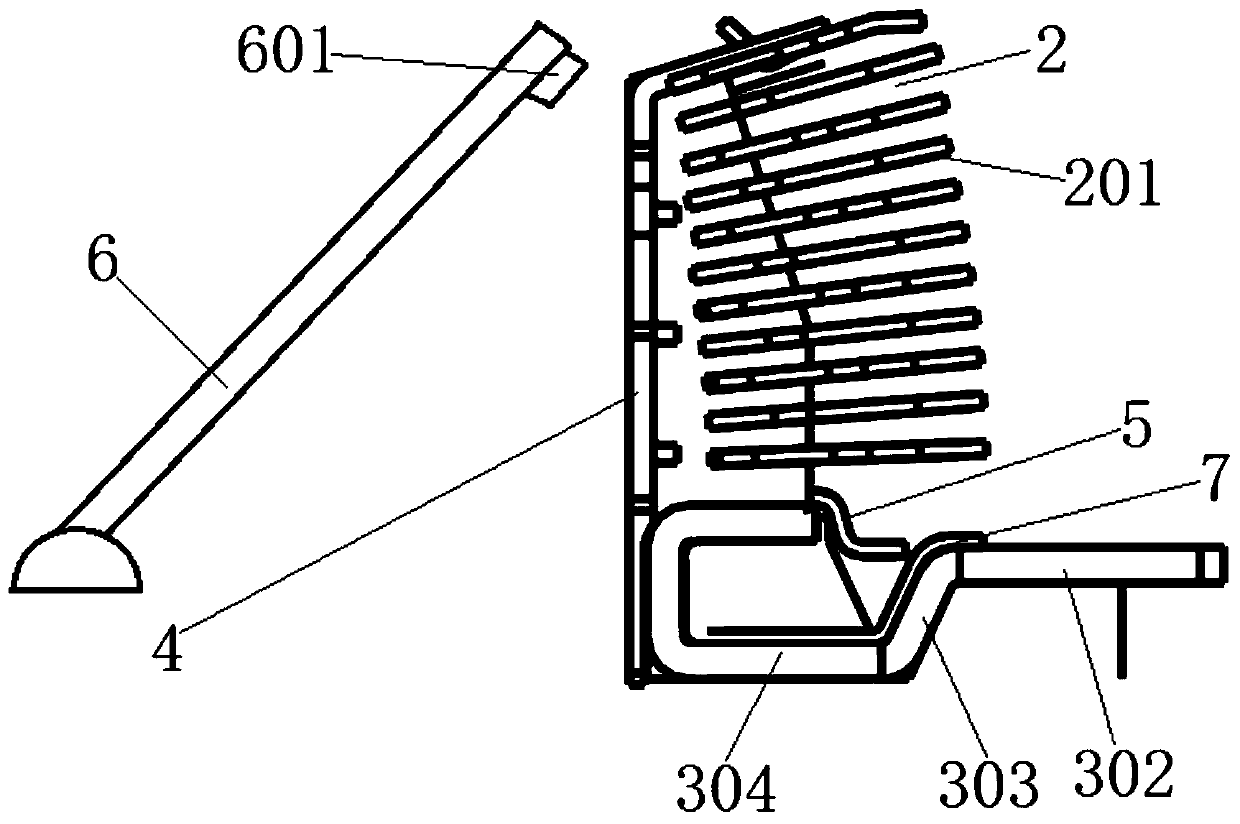

[0035] Such as image 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com