Cable laying device

A technology of cable laying and beams, applied in the direction of cable laying equipment, etc., can solve problems such as difficult cable laying, achieve the effects of improving installation and disassembly efficiency, light weight, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

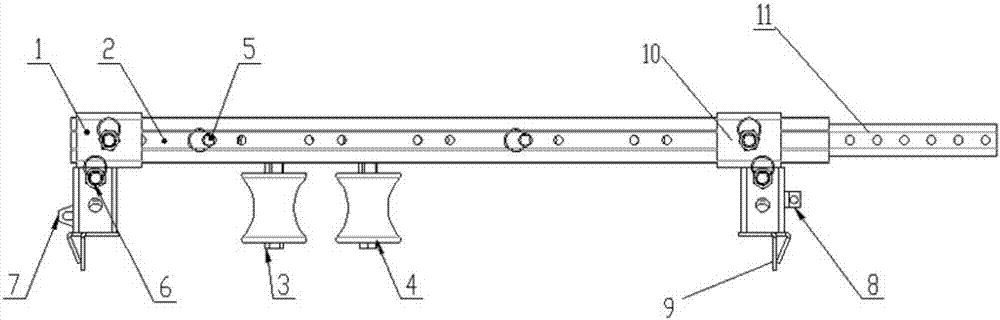

[0024] Such as figure 1 As shown, the cable laying device includes a fixing seat 1 and a beam 2.

[0025] The fixed base 1 includes a main fixed base and a secondary fixed base, the lower ends of the main fixed base and the secondary fixed base are respectively provided with snap-in structures 9, the upper end of the fixed base 1 is provided with mounting holes, and the beam 2 is provided with several positioning holes, The two ends of the crossbeam 2 are installed on two fixed seats respectively, and are fastened by the pull ring indexing pin 6; two pulley assemblies 3 and 4 are installed on the crossbeam, and the binding device can make the cable laying device quickly and stably installed on the On bridges of various widths, the selected standard parts on the market have high versatility;

[0026] A detachable connection structure is provided between the main fixing seat and the secondary fixing seat.

[0027] For better carrying and disassembly, the fixing base is made in...

Embodiment 2

[0031] The beam 2 includes a main beam and a slave beam 11. The main beam adopts a C-shaped steel structure, and the slave beam 11 adopts a square tube structure. The slave beam is nested in the main beam, and a compression spring is arranged between the main beam and the slave beam 11; There are positioning holes 5 on the slave beam, one pulley assembly 3 in the two pulley assemblies is fixed on the main beam, the other pulley assembly 4 is fixed on the slave beam 11, and the two pulley assemblies 3, 4 are on the master and slave beams The position can be adjusted by yourself. The pulley assembly is composed of a square tube and a pulley assembly; the square tube is provided with a row of round holes, which can be adapted to the installation and fixing of cables of various specifications; the pulley is made of nylon material, which is light in weight, good in hardness and flexibility. The groove of the pulley can bear the laying of the largest cable, and the R angle of the ed...

Embodiment 3

[0034] A clasp 9 is provided on the outside of the clamping device, and the connection structure is an automatic binding device whose main body is high-strength nylon. One end of the high-strength nylon is provided with a hook, and the other end is provided with an automatic locking structure.

[0035] When laying cables on site, the two fixing seats are respectively clamped on the two ladder sides of the bridge frame, the hook on the automatic binding device is hung on the clasp outside of one clamping structure, and the automatic locking device is fixed on the other clamping joint. On the clasp on the outside of the structure, the automatic locking device is operated to quickly fix the laying device, improve the installation efficiency and reduce the construction intensity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com