A piston thermoelectric power generation device based on temperature feedback control

A technology of thermoelectric power generation and temperature feedback, which is applied in the direction of internal combustion piston engines, pistons, generators/motors, etc., can solve problems such as poor reliability, reduce the load of the oil pump, simplify the power supply line, and reduce the temperature of the cold end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

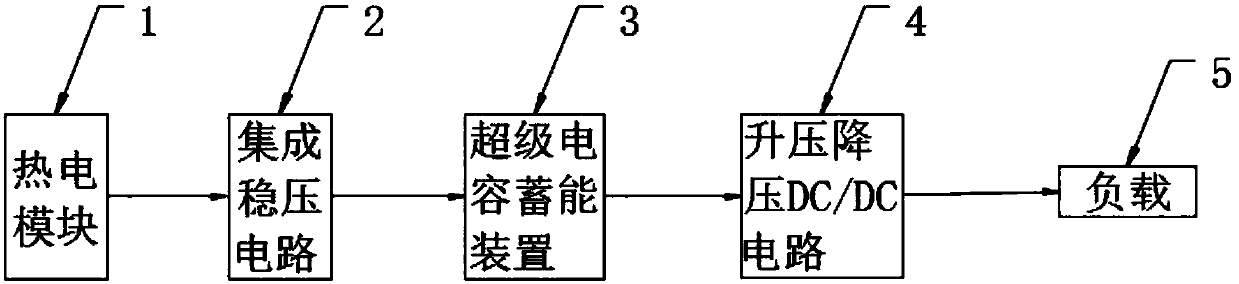

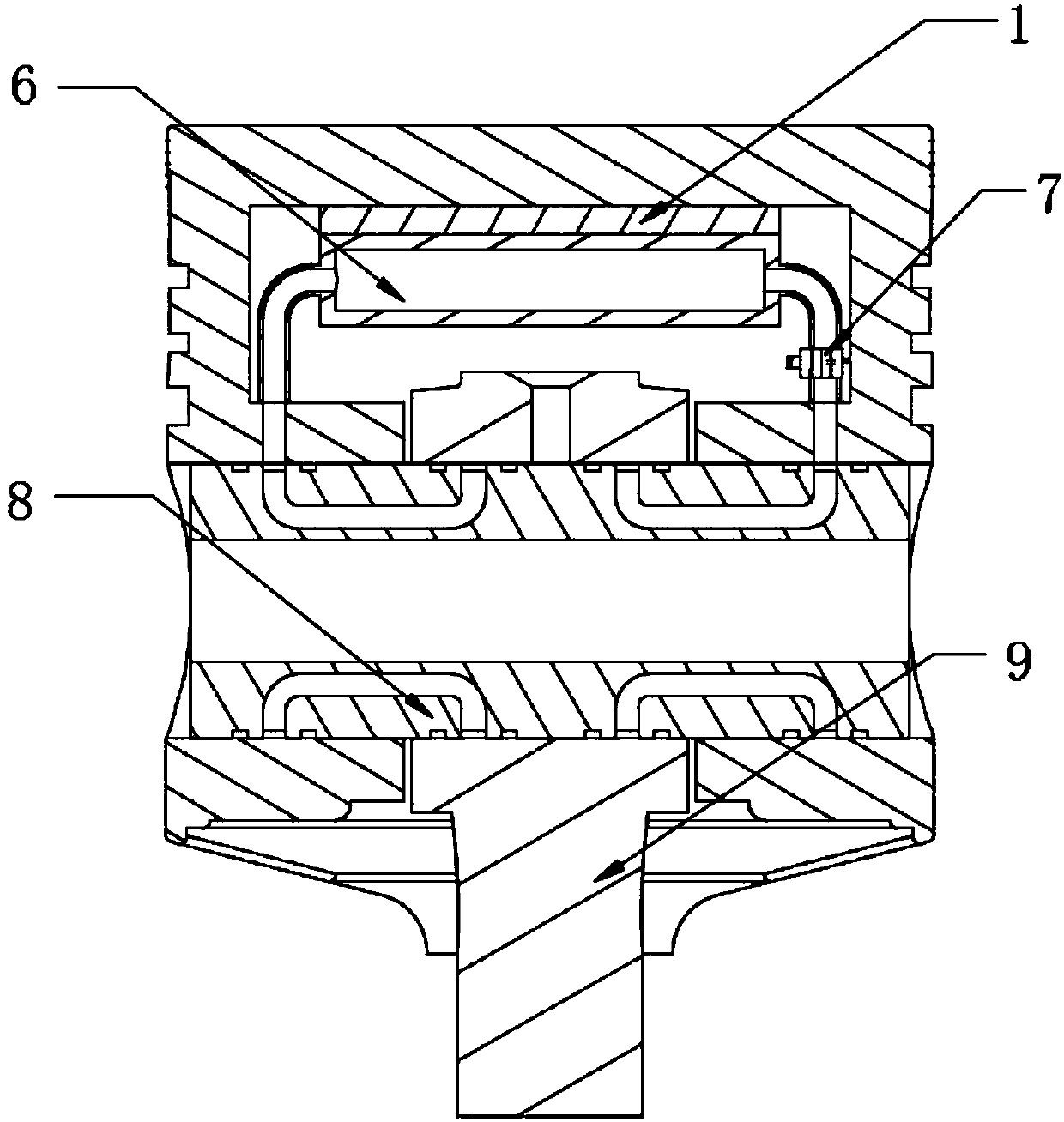

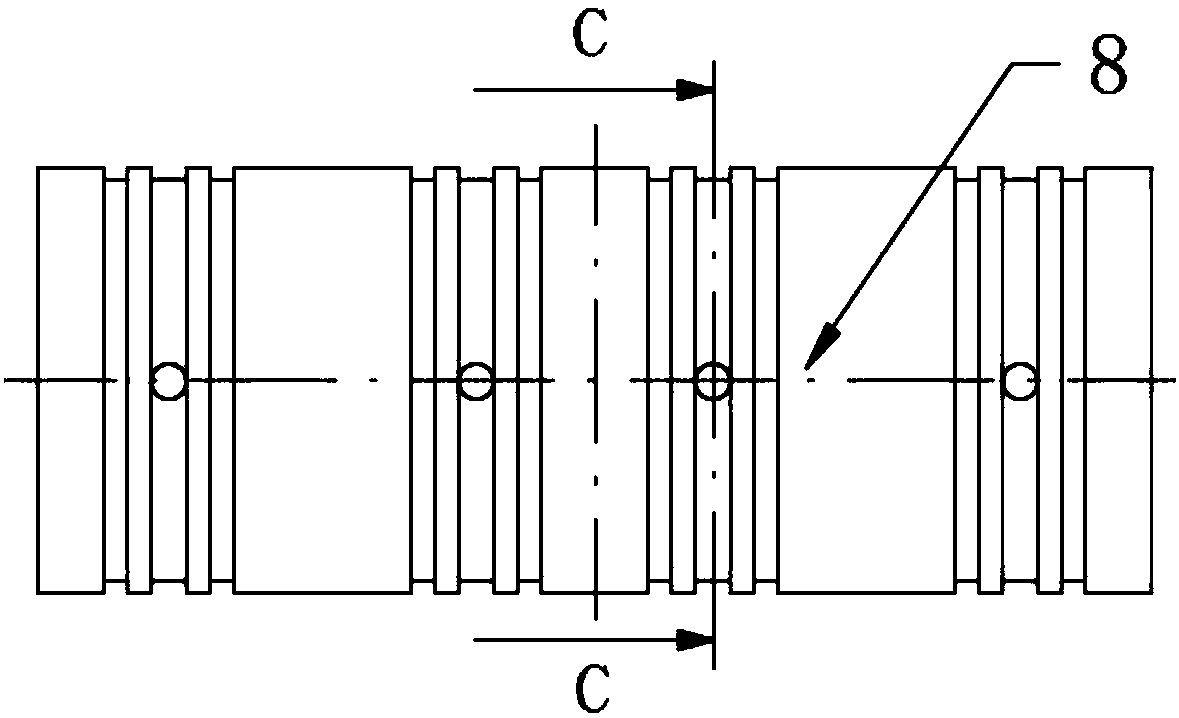

[0038] Such as figure 1 and figure 2 As shown, a piston thermoelectric power generation device based on temperature feedback control according to the present invention includes a thermoelectric module 1, an integrated voltage stabilizing circuit 2, a supercapacitor energy storage device 3, a step-up and step-down DC / DC circuit 4, and a load 5 , Cooling device 6, solenoid valve 7, piston pin 8, connecting rod 9, first thermocouple 10, second thermocouple 11, micro control unit MCU12.

[0039] The thermoelectric module 1, the integrated voltage stabilizing circuit 2, the supercapacitor energy storage device 3, and the step-up and step-down DC / DC circuit 4 are connected in sequence, and the output terminal of the step-up and step-down DC / DC circuit 4 is connected to the load 5.

[0040] The thermoelectric module 1 is installed on the top surface inside the piston, the hot end of the thermoelectric module 1 is close to the top surface inside the piston, and the cooling device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com