Probiotic fermented milk and its production process

A production process and fermented milk technology, applied in the direction of dairy products, streptococcus/lactococcus, lactobacillus, etc., can solve the problems of complicated production process and high production cost, shorten the time required for fermentation, simplify the production process, and strengthen intestinal tract The effect of immune function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

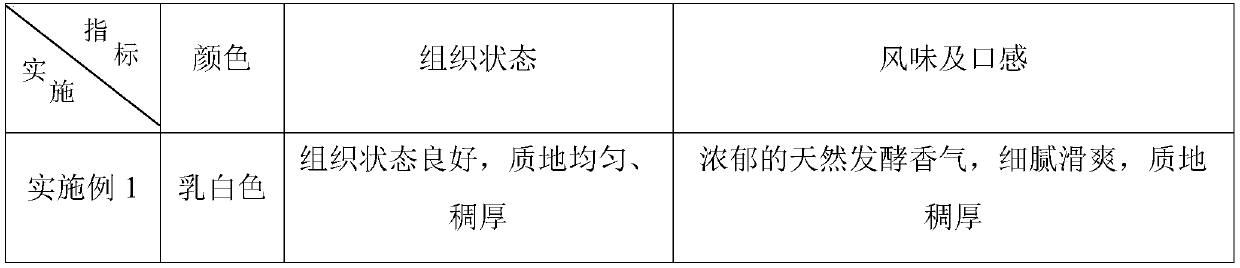

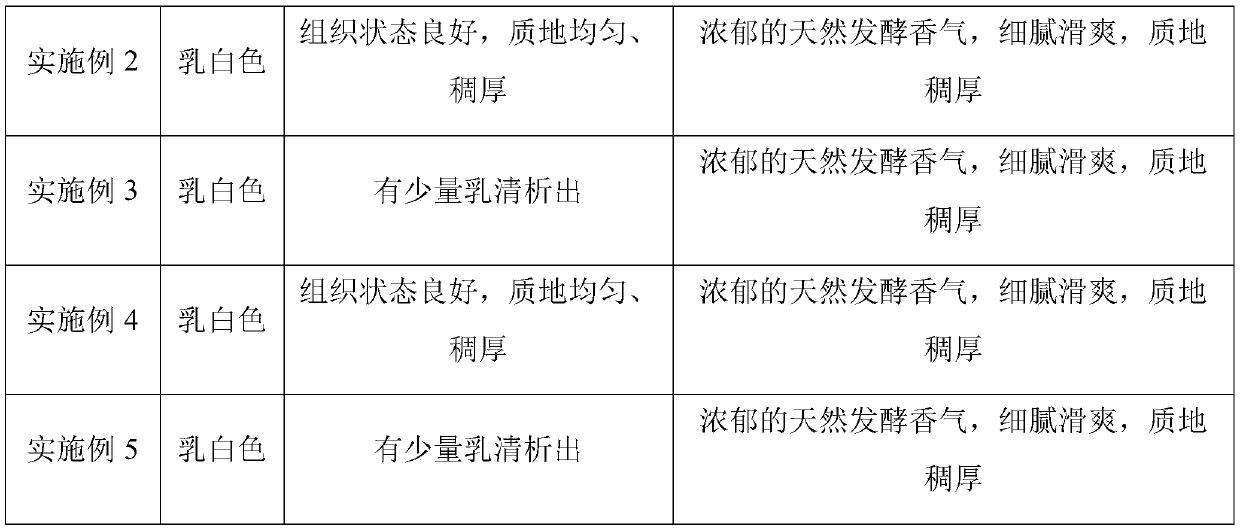

Embodiment 1

[0024] The manufacturing process steps of probiotic fermented milk are as follows:

[0025] (1) Pretreatment: preheat the milk at 50-60°C, the temperature is 60-70°C, the pressure is 15-20MPa, homogeneous, 90-95°C, 5min heat preservation type sterilization;

[0026] (2) Centrifugal separation: Centrifugal skim the pretreated milk at a centrifugal speed of 2500-3000rpm, separate raw milk 800±100L per hour, divide it into semi-skimmed milk and cream, and obtain the fat content of the semi-skimmed milk 1.7wt%;

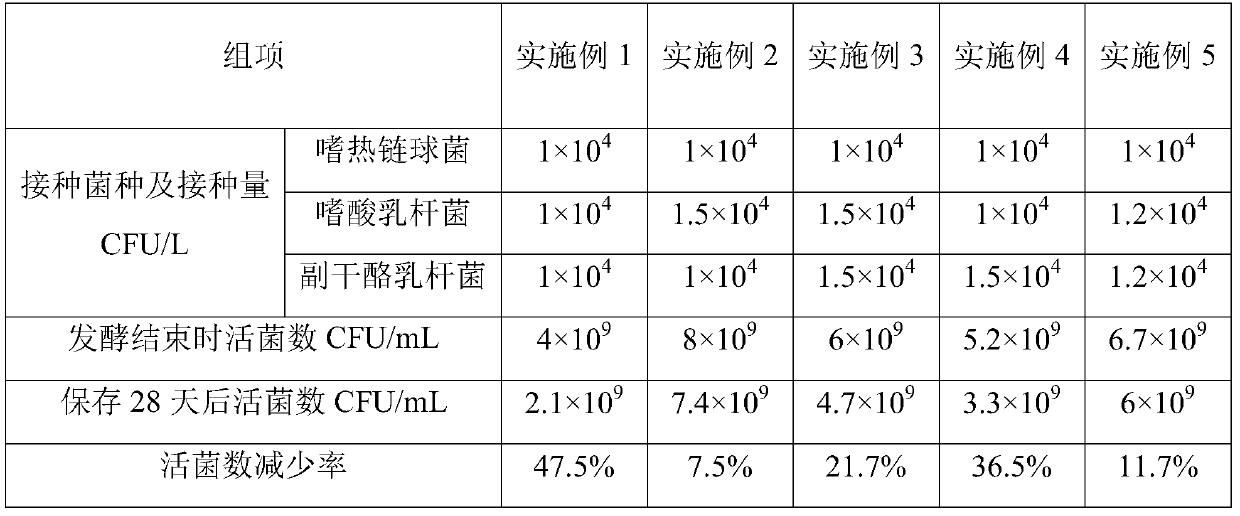

[0027] (3) Fermentation: Homogenize the semi-skimmed milk at a temperature of 60-70°C and a pressure of 15-20 MPa, add the mixed strains of Streptococcus thermophilus, Lactobacillus acidophilus and Lactobacillus paracasei, thermophilic The inoculum ratio of Streptococcus, Lactobacillus acidophilus and Lactobacillus paracasei is 1:1:1, heat preservation and fermentation at 40°C, and when the temperature rises to 60°C and the pH is 4.6±0.1, quickly cool down to 35-37°C , ...

Embodiment 2

[0031] The manufacturing process steps of probiotic fermented milk are as follows:

[0032] (1) Pretreatment: preheat the milk at 50-60°C, the temperature is 60-70°C, the pressure is 15-20MPa, homogeneous, 90-95°C, 5min heat preservation type sterilization;

[0033] (2) Centrifugal separation: Centrifugal skim the pretreated milk at a centrifugal speed of 2500-3000rpm, separate raw milk 800±100L per hour, divide it into semi-skimmed milk and cream, and obtain the fat content of the semi-skimmed milk 1.7wt%;

[0034] (3) Fermentation: Homogenize the semi-skimmed milk at a temperature of 60-70°C and a pressure of 15-20 MPa, add the mixed strains of Streptococcus thermophilus, Lactobacillus acidophilus and Lactobacillus paracasei, thermophilic The inoculum ratio of Streptococcus, Lactobacillus acidophilus and Lactobacillus paracasei is 1:1.5:1, heat preservation and fermentation at 40°C, and when the temperature rises to 60°C and the pH is 4.6±0.1, quickly cool down to 35-37°C ...

Embodiment 3

[0038] The manufacturing process steps of probiotic fermented milk are as follows:

[0039] (1) Pretreatment: preheat the milk at 50-60°C, the temperature is 60-70°C, the pressure is 15-20MPa, homogeneous, 90-95°C, 5min heat preservation type sterilization;

[0040] (2) Centrifugal separation: Centrifugal skim the pretreated milk at a centrifugal speed of 2500-3000rpm, separate raw milk 800±100L per hour, divide it into semi-skimmed milk and cream, and obtain the fat content of the semi-skimmed milk 1.7wt%;

[0041] (3) Fermentation: Homogenize the semi-skimmed milk at a temperature of 60-70°C and a pressure of 15-20 MPa, add the mixed strains of Streptococcus thermophilus, Lactobacillus acidophilus and Lactobacillus paracasei, thermophilic The inoculum ratio of Streptococcus, Lactobacillus acidophilus and Lactobacillus paracasei is 1:1.5:1.5, heat preservation and fermentation at 40°C, and when the temperature rises to 60°C and the pH is 4.6±0.1, quickly cool down to 35-37°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com