Operating valve and railway vehicle braking system

A technology for acting valves and valve stems, applied in brakes, brake components, railway vehicles, etc., can solve problems such as damage, poor pressure holding effect, and reduced control accuracy of acting valves, and achieve rapid control, good sealing effect of the valve port, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

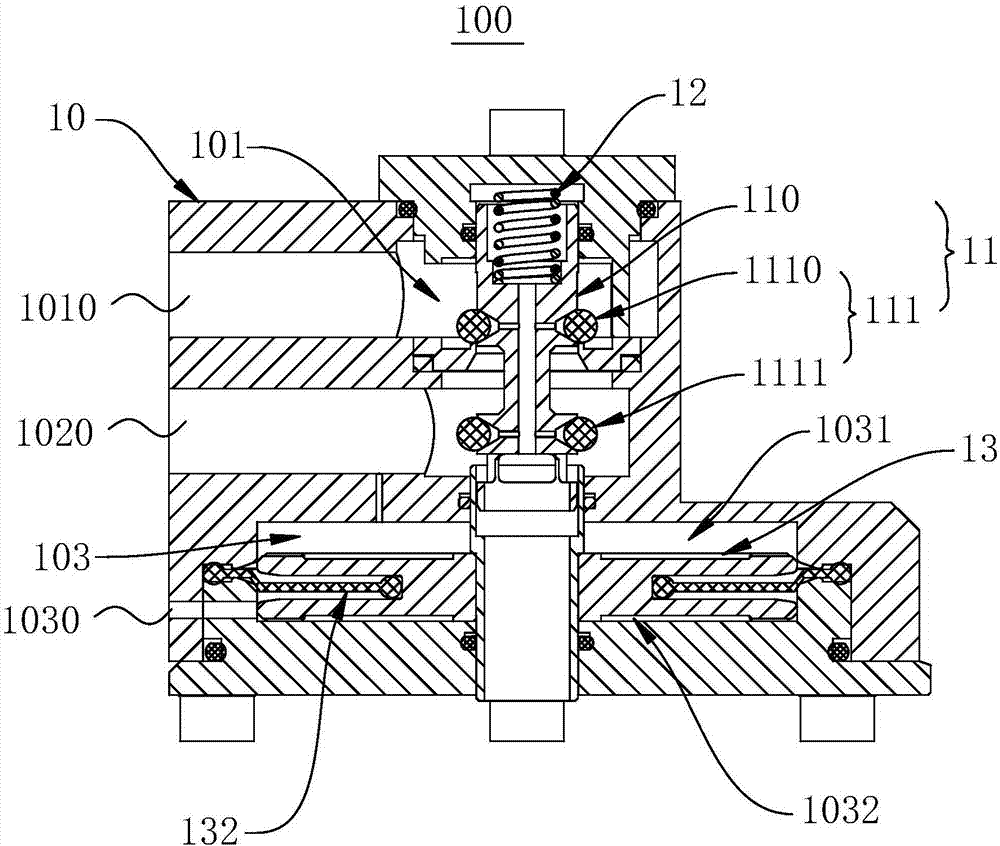

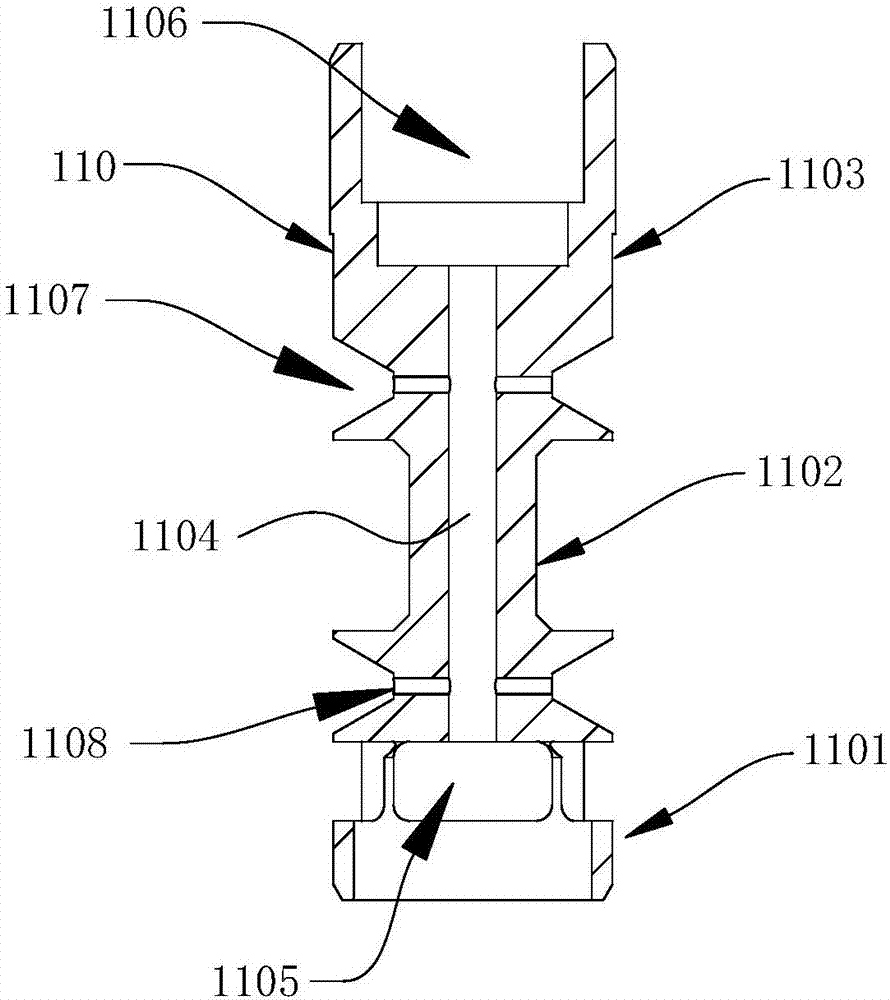

[0033] Please refer to figure 1 , this embodiment provides an action valve 100 , including a valve body 10 , a valve stem assembly 11 , a return assembly 12 and a control assembly 13 .

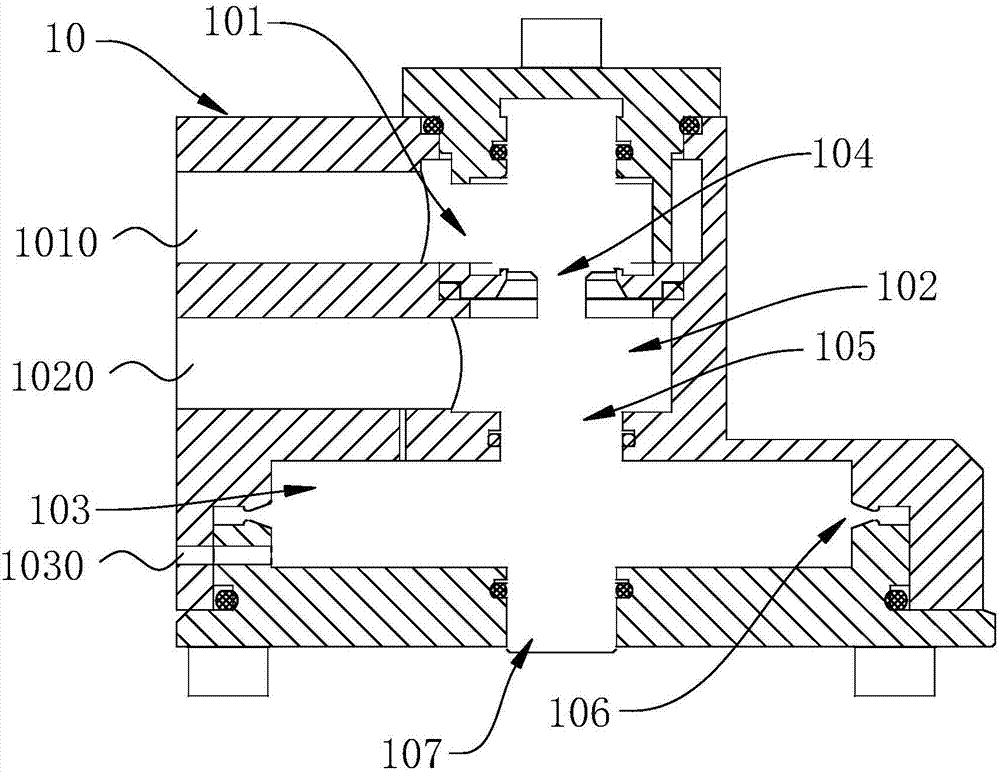

[0034] Such as figure 2 As shown, the valve body 10 is provided with at least three connected chambers, and each chamber is provided with a channel communicating with the outside, and the three chambers are respectively the main air chamber 101, the output chamber 102 and the pre-control chamber 103, The main air chamber 101 communicates with the output chamber 102 through the first valve port 104 , and the output chamber 102 communicates with the pre-control chamber 103 through the second valve port 105 .

[0035]As an optional solution of this embodiment, the valve body 10 is provided with three chambers, namely, the main air chamber 101 , the output chamber 102 and the pre-control chamber 103 . Such as figure 2 As shown, the total air chamber 101 is provided with a total air channel 10...

no. 2 example

[0052] This embodiment provides a rail vehicle brake system, including a brake assembly and the action valve 100 provided in the first embodiment, and the action valve 100 is used to control the brake assembly.

[0053] In this implementation, the action valve 100 can realize the function of increasing, decreasing and maintaining the output pressure, and the action valve 100 acts on the brake assembly, which can precisely control the brake assembly, thereby realizing precise braking of the rail vehicle and ensuring the safety of the rail vehicle run.

[0054]To sum up, the present invention provides an action valve 100 and a rail vehicle braking system. The action valve 100 can control the opening or closing of the valve port of the action valve 100 according to the change of the pre-control pressure, so as to realize the rise, fall and fall of the output pressure. Pressure maintaining function, the structure design of the action valve 100 is reasonable, the sealing effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com