A guide tube, a film thickness sensor and evaporation equipment

A technology of film thickness and guide tube, which is applied in the field of guide tube, film thickness sensor and evaporation equipment, and can solve the problem of inaccurate film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

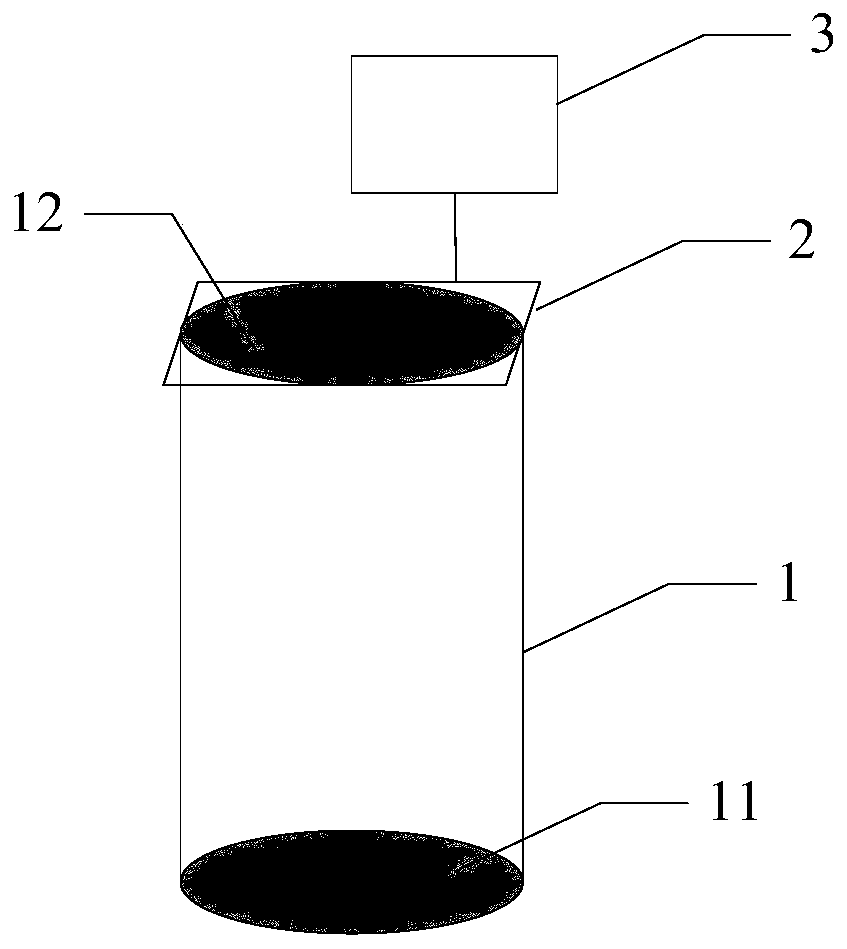

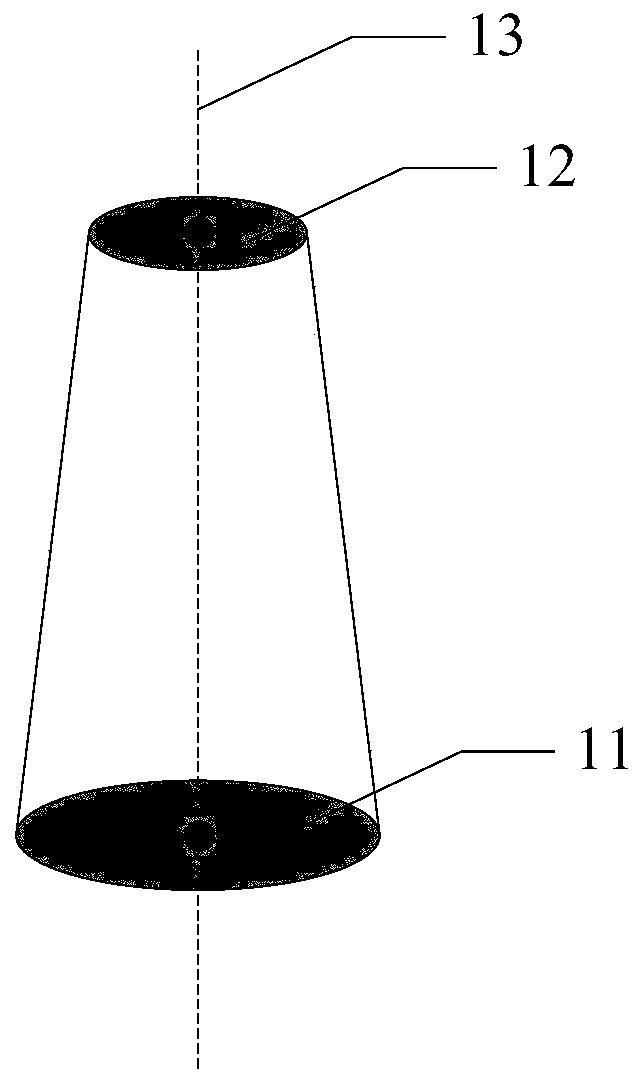

[0034] see figure 2 , a guide tube provided in Embodiment 1 of the present application is used for a film thickness sensor, the guide tube is hollow, and includes: an evaporation inlet 11 and an evaporation outlet 12; wherein, the evaporation inlet 11 has a cross-sectional area larger than the evaporation The cross-sectional area of the material outlet 12, from the evaporated material inlet 11 to the evaporated material outlet 12, the cross-sectional area of the guide pipe gradually decreases.

[0035] Because the cross-sectional area of the vapor deposition inlet 11 of the guide pipe is greater than the cross-sectional area of the vapor deposition outlet 12 of the guide pipe, like this, when the film thickness sensor using the guide pipe detects the thickness of the film, it can reduce the The influence of the accumulation of vapor deposition on the vapor deposition that can be sensed by the crystal vibrator is reduced, thereby reducing the influence of the accumulat...

Embodiment 2

[0041] The guide tube provided in Embodiment 2 of the present application is similar to the guide tube provided in Embodiment 1 of the present application, and the same parts will not be repeated here, and only the different parts will be described below.

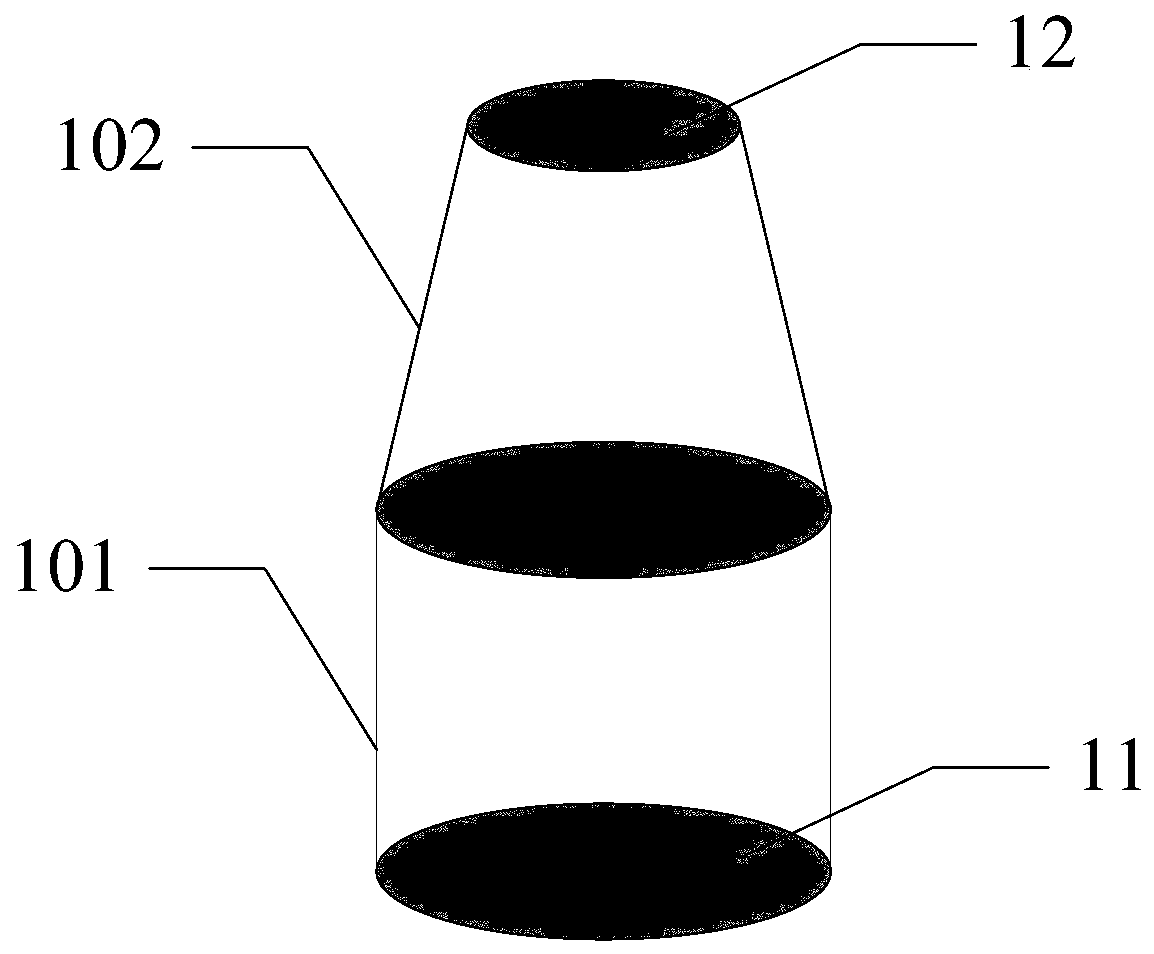

[0042] see image 3 , the guide pipe provided in Embodiment 2 of the present application is divided into two sections, from the vapor deposition inlet 11 to the vapor deposition outlet 12, the cross-sectional area of a section of the guide pipe 101 near the vapor deposition inlet 11 is the same as the cross-sectional area of the vapor deposition inlet 11 The area is the same, and the cross-sectional area of the other guide pipe 102 gradually decreases; if the cross-section of the guide pipe is circular, it can be expressed as a section of guide pipe from the vapor deposition inlet 11 to the vapor deposition outlet 12, which is close to the vapor deposition inlet 11. The caliber of 101 is the same as the caliber of the...

Embodiment 3

[0044] The guide tube provided in the third embodiment of the present application is similar to the guide tube provided in the first embodiment of the present application, and the same parts will not be repeated here, and only the different parts will be described below.

[0045] see Figure 4 , the guide pipe provided in Embodiment 3 of the present application is divided into two sections, from the vapor deposition inlet 11 to the vapor deposition outlet 12, the cross-sectional area of a section of the guide pipe 101 near the vapor deposition inlet 11 is gradually reduced to be equal to the vapor deposition The cross-sectional area of the outlet 12 is the same, and the cross-sectional area of the other guide pipe 102 is the same as the cross-sectional area of the vapor deposition outlet 12; if the cross section of the guide pipe is circular, it can be expressed as: The caliber of a section of the guide pipe 101 near the vapor deposition inlet 11 is gradually reduced t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com