Intelligent monitoring and controlling system for pretightening force and pretightening displacement of high-speed precise main shaft and control method thereof

An intelligent monitoring system and pre-tightening force technology, applied in manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., to achieve high positioning accuracy, high rigidity, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

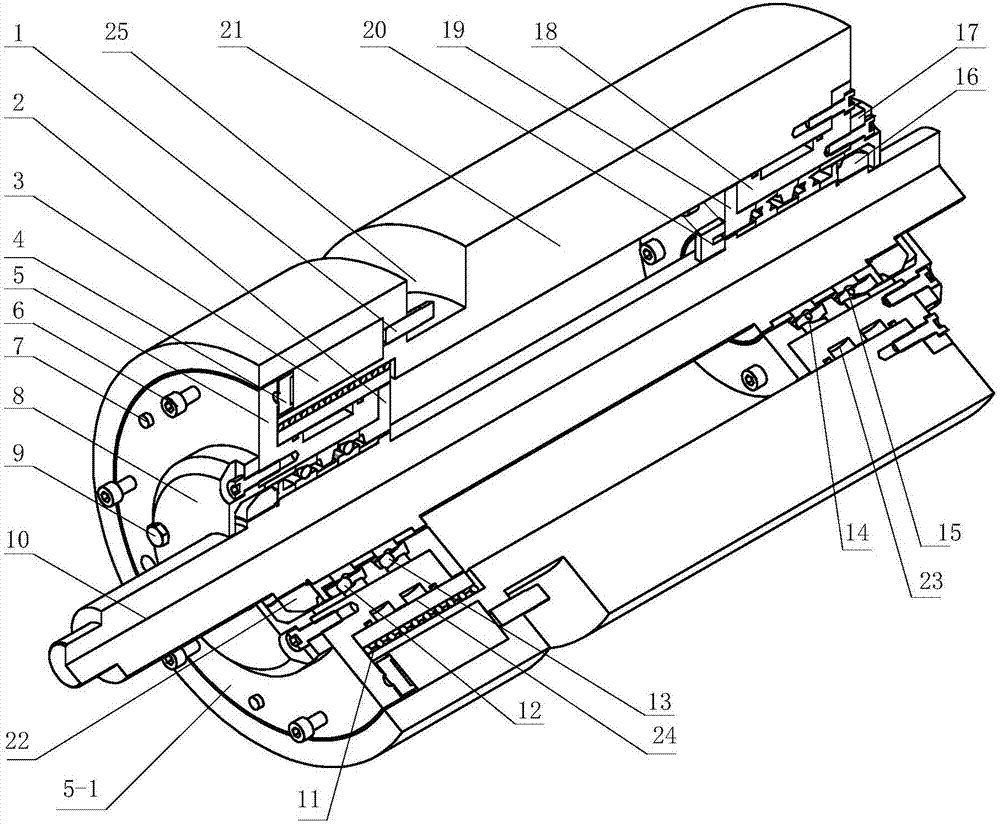

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

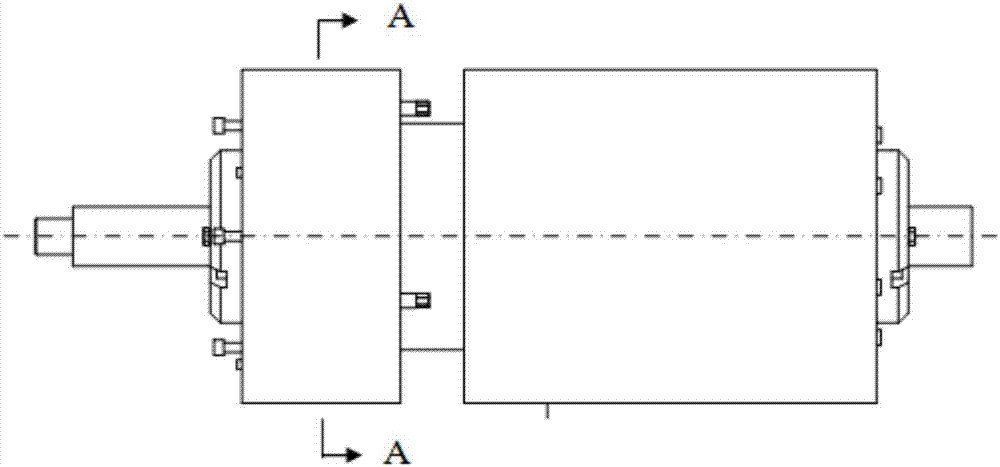

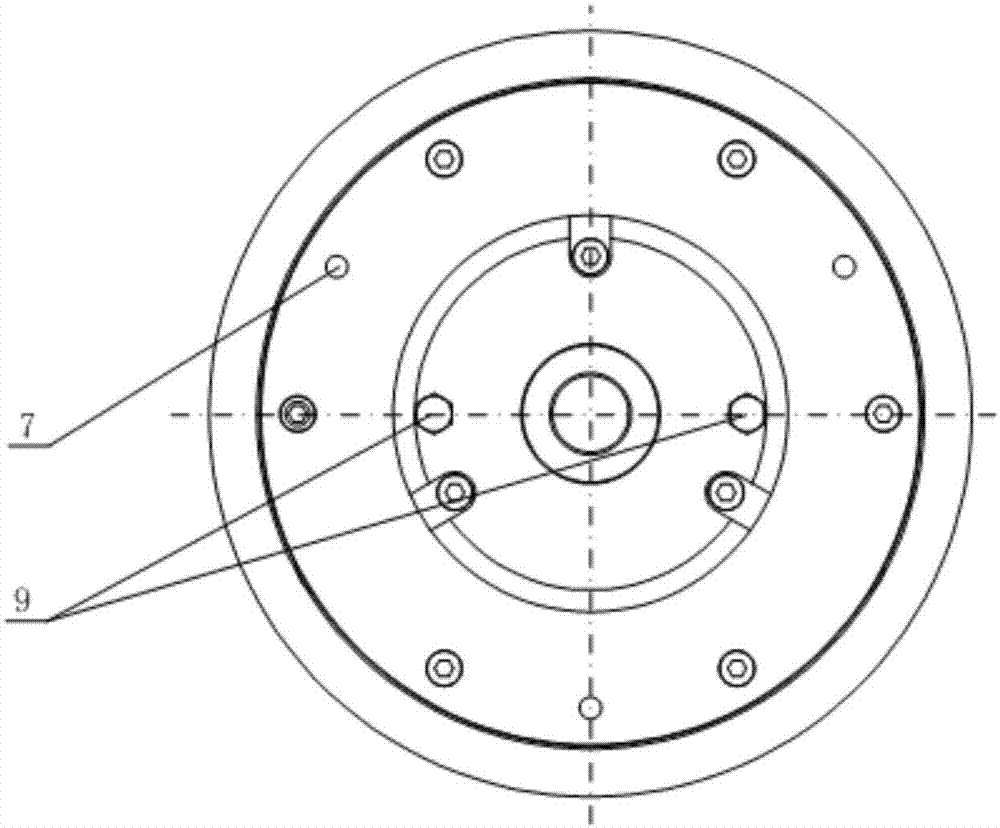

[0037] see Figure 1 to Figure 5 , an intelligent monitoring system for high-speed precision spindle preload and preload displacement, comprising a spindle housing 21, a spindle 10, a front sleeve assembly, a rear sleeve assembly, a piezoelectric actuator assembly, and a data acquisition and control system;

[0038] The main shaft housing 21 is a cylindrical structure with an inner cavity for installation, and the main shaft housing 21 is provided with an installation inner cavity for installing the front sleeve assembly, the rear sleeve assembly, and the main shaft;

[0039] The front sleeve assembly includes a front sleeve 18, a positioning end cover 19, and a front end cover 17. The front sleeve 18 is fixedly installed in the main shaft ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com