Windscreen wiper

A wiper and scraper technology, which is applied in the field of wiper, can solve the problems of slightly larger steering adjuster design, increased wind resistance of the car, and insufficient connection of fixed methods, and achieve simple and ingenious structural design, light weight, and compact and stable wiper overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

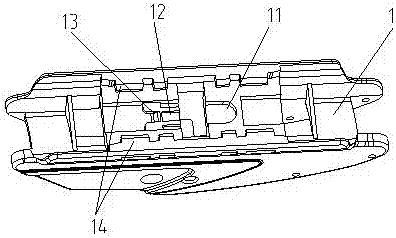

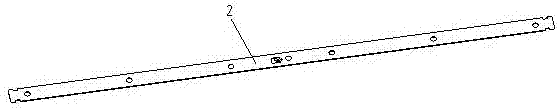

[0025] Such as Figure 1~7 As shown, a wiper blade, which includes an arm connecting fixture 1 and an elastic sheet 2; wherein,

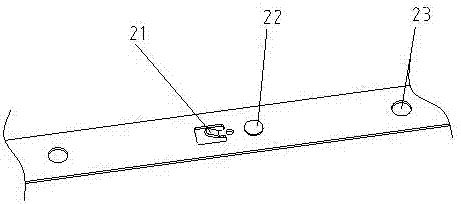

[0026] The elastic sheet 2 is provided with an upwardly tilted buckle 21 and an upwardly protruding limiting platform 22;

[0027] The arm connecting fixture 1 is provided with a wrapping groove for wrapping at least a part of the elastic piece 2 and limiting the elastic piece 2 to move up and down, forward and backward on the arm connecting fixture 1, and the arm connecting fixture 1 is also provided with There is a limit slot 11 snap fit with the limit table 22 and a snap slot 12 snap fit with the buckle 21; The buckle 21 snaps into the slot 12 and at least limits the movement of the elastic piece 2 to the left on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com