Design method for coating double correction blades

A design method, the technology directly above, applied in the design field of coating double correction vane, can solve the problems of increasing processing cost, reducing the life of the correction vane cylinder, etc., to achieve the effect of improving uniformity, reducing abnormal air leakage, and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

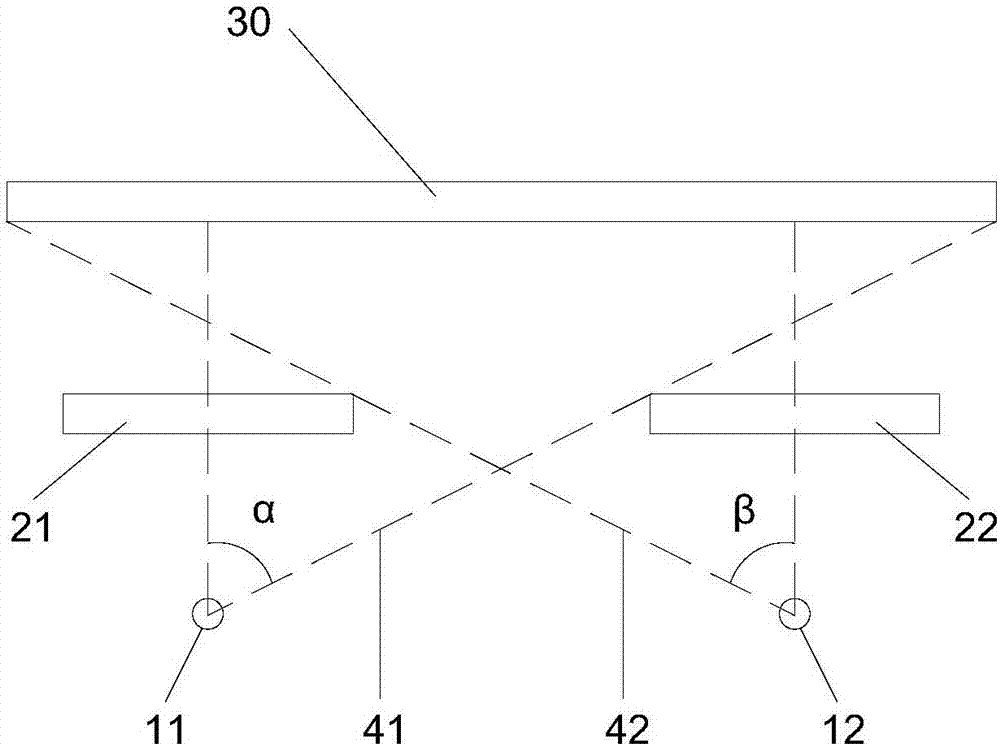

[0013] refer to figure 1 .

[0014] The invention discloses a method for designing double correcting leaves for coating, which includes the following steps: setting a first evaporation source 11 and a second evaporation source 12 in a coating machine, a first correction leaf 21 is arranged directly above the first evaporation source 11, a second The second correction lobe 22 is arranged directly above the second evaporation source 12, and the substrate 30 is arranged above the first correction leaf 21 and the second correction leaf 22; the first evaporation source 11 is located on the left side, and the second evaporation source 12 is located on the right side. side, the evaporation path from the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com